10

INSTALLATION

Unpacking the product

UNPACKING THE PRODUCT

The solar collectors are packed in various ways depending

on the number of units supplied:

A

In a pack of 1

B

Packages of 5 collectors

Pallet contents:

- collector

- documentation envelope containing certicate of

warranty and label with bar code.

b

Keep the front of the packaging and use it to shade

the glass tubes before the system is started up.

If the solar collectors are not going to be put into oper-

ation immediately, and there is any risk of their being

exposed to rain, do not use the packaging to shade

them as it is not water-proof.

b

The instruction manual is an integral part of the so-

lar connector. Once located, read it thoroughly and

keep it safe.

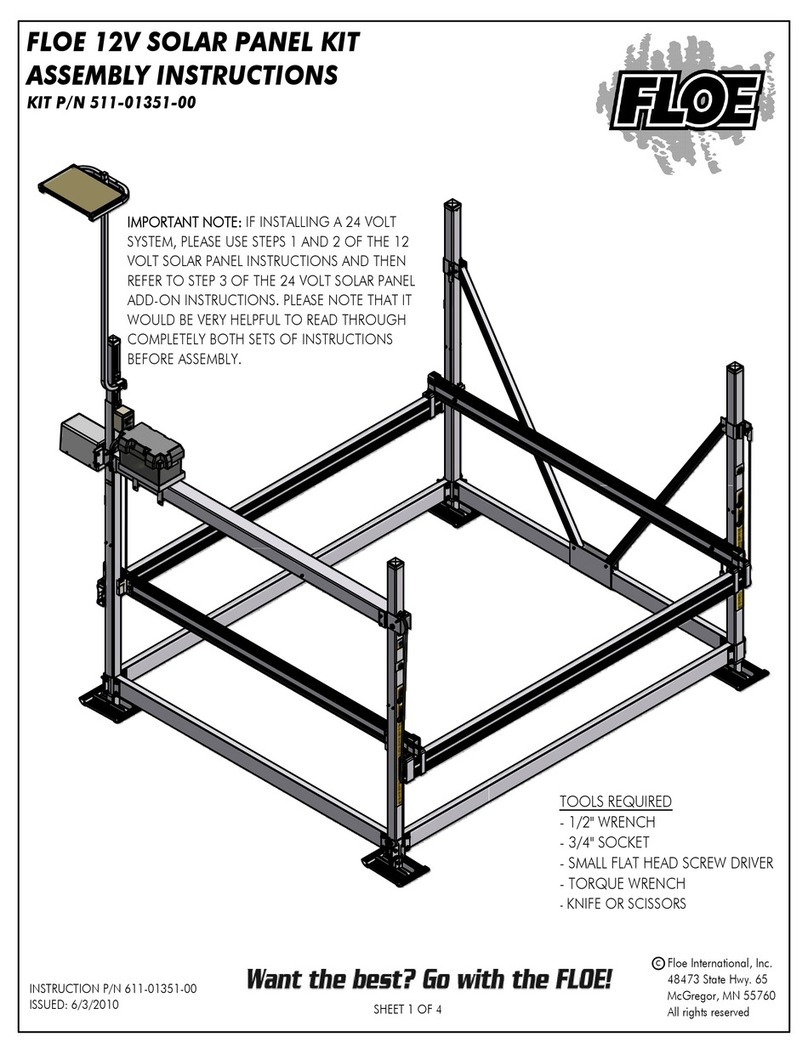

Handling

Once you have removed the outer packaging, proceed as

follows to unpack and handle the solar collector:

- Remove the PVC wrapping to free the solar collector

from the pallet

- Tilt the solar collector slightly and grip it at the four

points shown (A) to lift it.

- Use a hoist or other suitable lifting equipment to hoist

the solar collector on to the roof.

b

Wear suitable personal protective equipment and

use suitable safety devices.

a

Do not dispose of packaging material into the envi-

ronment, or leave it within the reach of children, since

it can become a potential hazard. Dispose of packag-

ing material in compliance with applicable legislation.

a

Do not lift the solar collector by its water ttings.

A

A

A

HANDLING

Installation