3

GB

2. Safety regulations

Warning:

Never use the high-pressure cleaner with

inflammable, toxic or other such liquids as could

impair the correct operation of the high-pressure

cleaner. Risk of explosion or poisoning!

Never direct the water jet at persons, animals or

plants.

To avoid the risk of electrical shock, never direct

the water jet at the machine itself, at electrical

parts or other electrical equipment.

Never use the high-pressure cleaner in the rain.

Risk of short-circuiting!

Never allow the high-pressure cleaner to be used

by children or unauthorized persons. Risk of

injury!

Never touch the plug or socket-outlet with wet

hands as this could result in electric shock!

Never operate the high-pressure cleaner when

the mains cable is damaged. Risk of electric

shock and short-circuiting!

Never operate the high-pressure cleaner with a

damaged high-pressure hose. Risk of bursting!

Never lock the pistol trigger in the ON position.

Risk of injury!

Never change or adjust the setting of the control

valve. Risk of bursting!

To avoid malfunctioning, never change the

original diameter of the water jet.

Never leave the high-pressure cleaner

unattended.

To avoid the risk of short-circuiting, do not carry

the high-pressure cleaner by the mains cable.

Safety precautions

To avoid short-circuiting, all live parts must be

protected against the water jet.

Connect up the high-pressure cleaner only to an

approved, earthed power source. An earth-

leakage circuit-breaker (30 mA) will provide

additional personal protection.

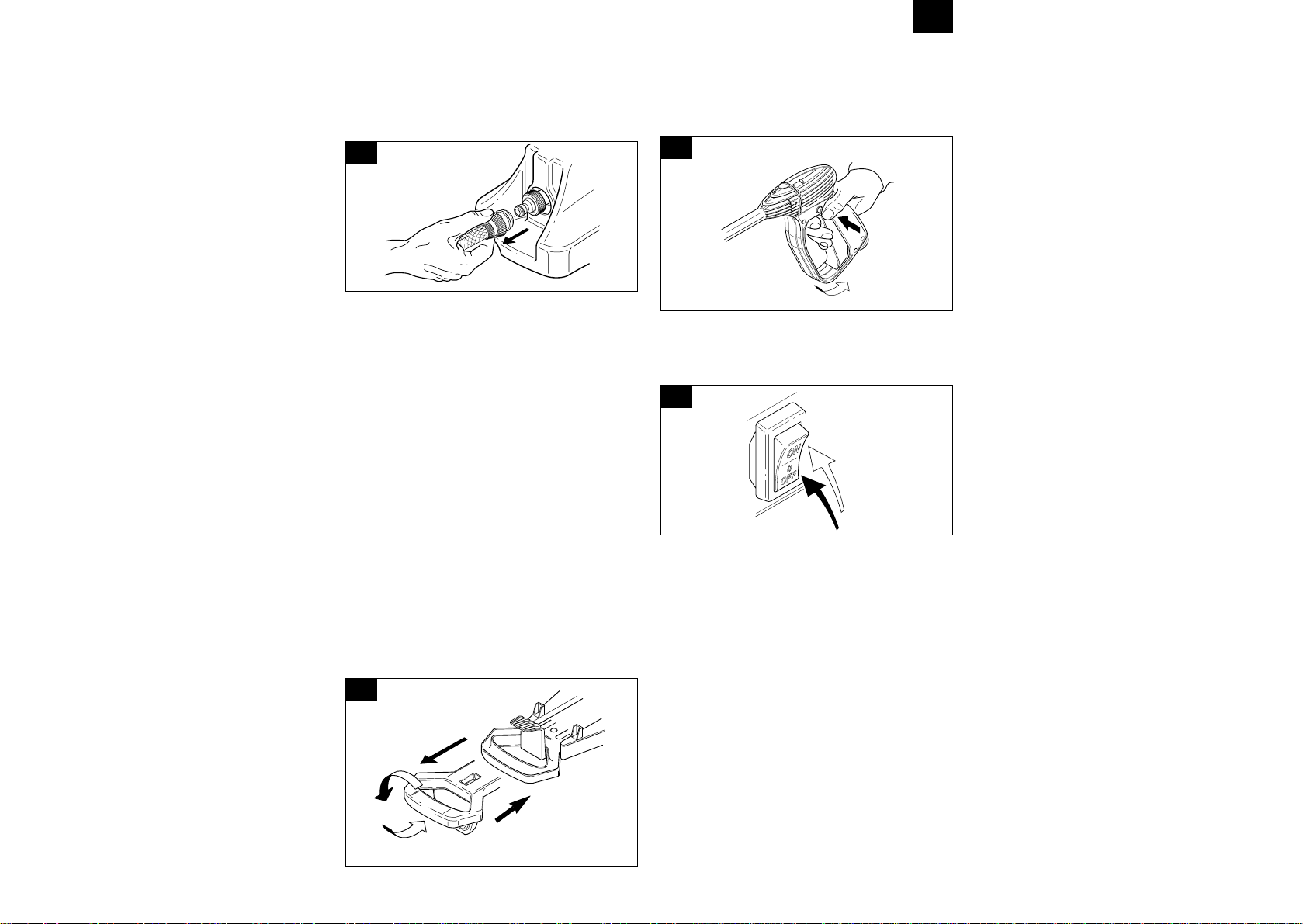

As the high pressure can cause parts to

rebound, always wear protective clothing and

goggles when operating the machine.

To prevent the high-pressure cleaner from

starting up by accident, always disconnect from

the mains before doing any maintenance or

repair work on the machine.

As the high-pressure jet has a kickback effect,

make sure you have a firm hold of the pistol

when pressing trigger.

Observe the regulations of your local water

board. Under DIN 1988, the high-pressure

cleaner can be connected up to the drinking-

water supply only if the feed pipe is fitted with a

safety device to prevent backwater with

drainage.

The electrical parts must be serviced and

repaired only by a qualified electrician.

Always release the residual pressure before

disconnecting the hose from the high-pressure

cleaner.

Make sure the screwed parts are screwed on

tightly and check the other components of the

high-pressure cleaner for damage or wear and

tear both before use and at regular intervals.

Make sure that people and animals do not come

within 15 m of the high-pressure cleaner when in

use.

3. General regulations

Please keep these instructions carefully for

future reference.

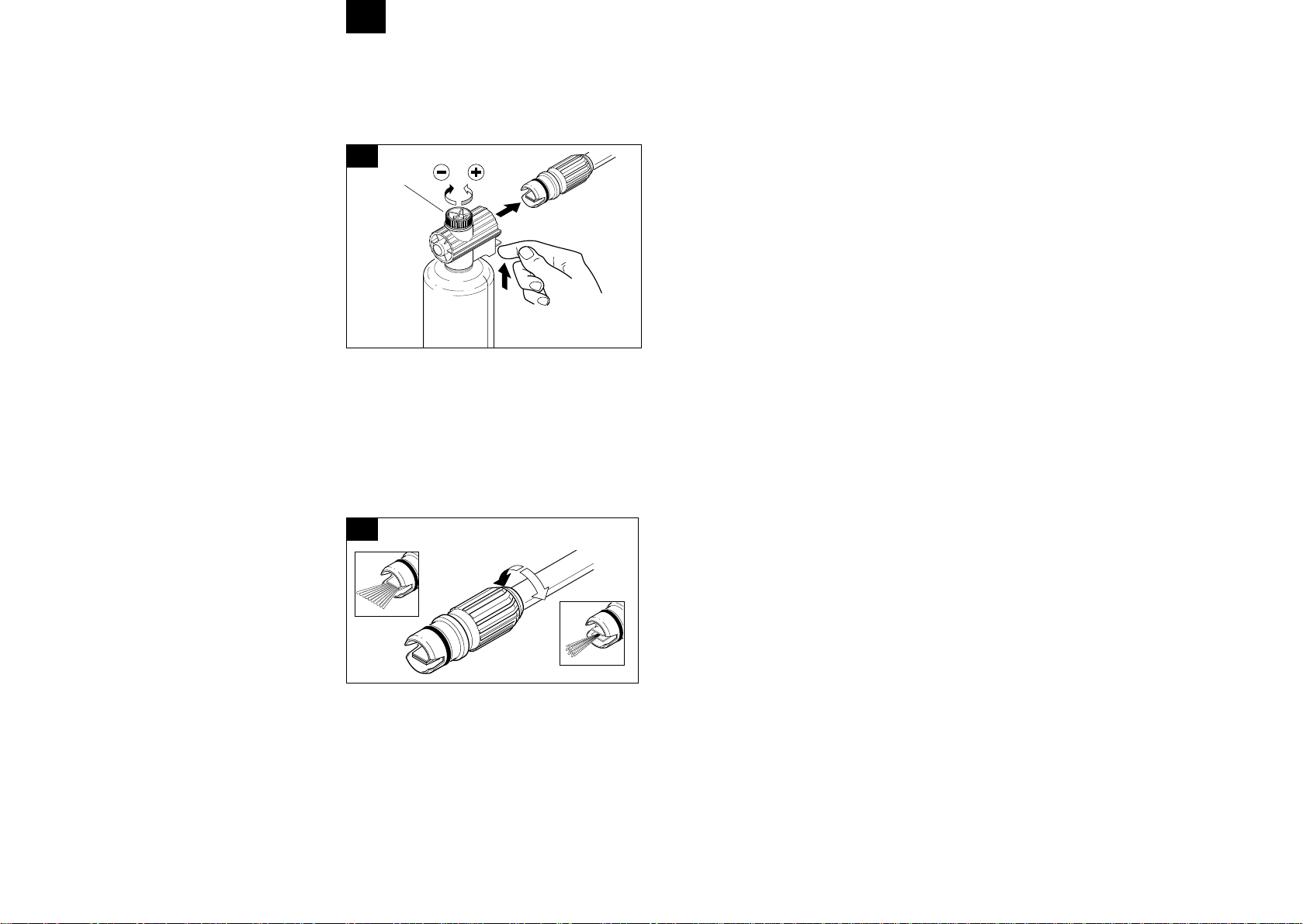

Before switching on the high-pressure cleaner,

make sure the water supply is in good working

order. Dry running will cause serious damage to

the seals.

Never pull on the mains cable in order to remove

the plug.

If the high-pressure cleaner is too far away from

the objects to be cleaned, do not move it by

pulling the high-pressure hose but instead use

the handle provided.

To avoid damaging the seals, do not operate the

high-pressure cleaner for longer than 1 minute

when the pistol is closed.

In the winter months, store the high-pressure

cleaner in a frost-free place.

Make sure the air vents are not blocked when

operating the machine.

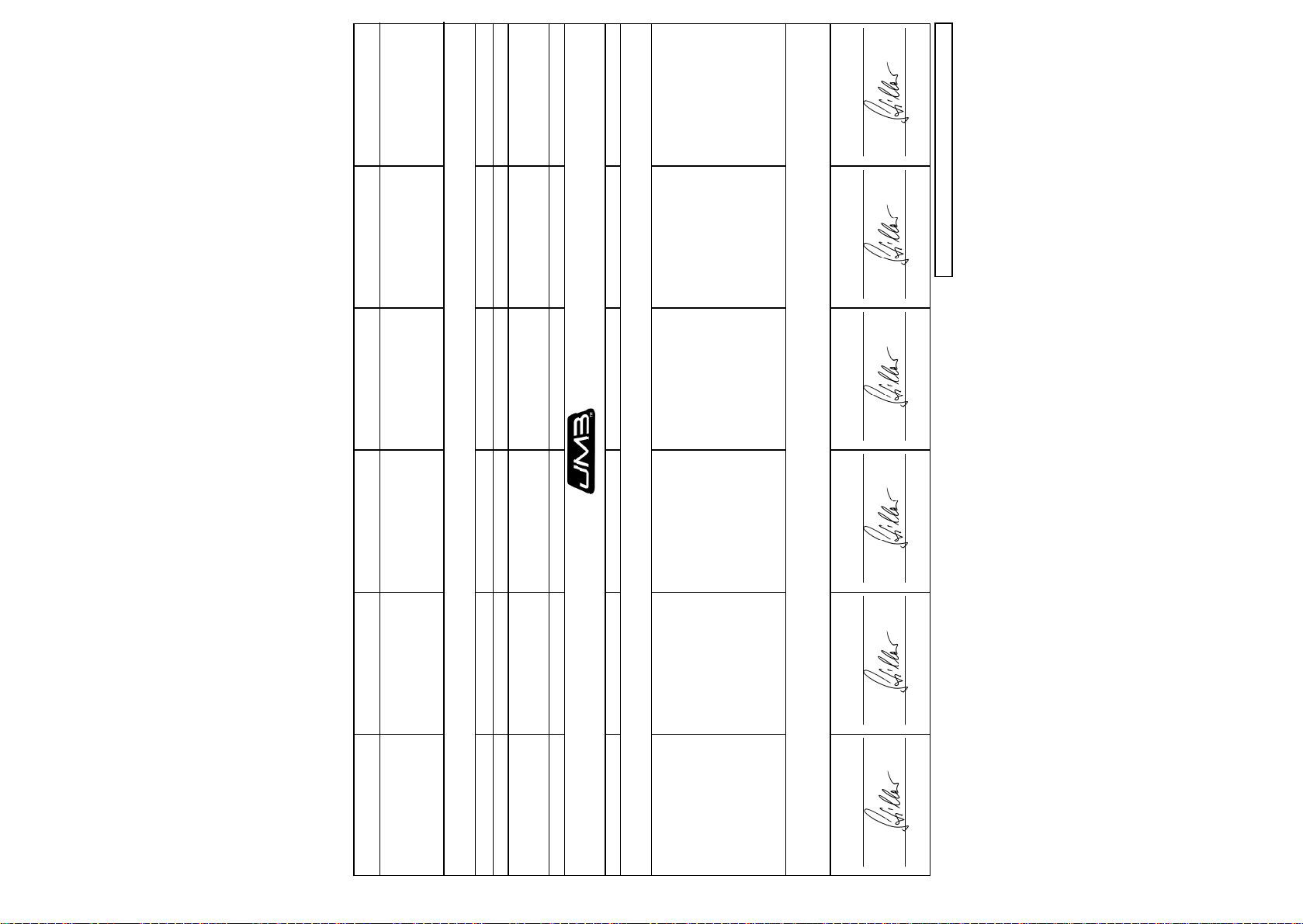

The cross-section of the extension cable must be

in keeping with the length, i.e. the longer the

lead, the thicker the cable must be. Furthermore,

use only cables of the protection type „IP X 5“.

The exact values are listed in the table.