8.917-986.0 • DBA • Rev. 12/10

5

PRESSURE WASHER OPERATOR’S MANUAL

12. Never make adjustments on machine while in op-

eration.

13. Be certain all quick coupler fittings are secured

before using pressure washer.

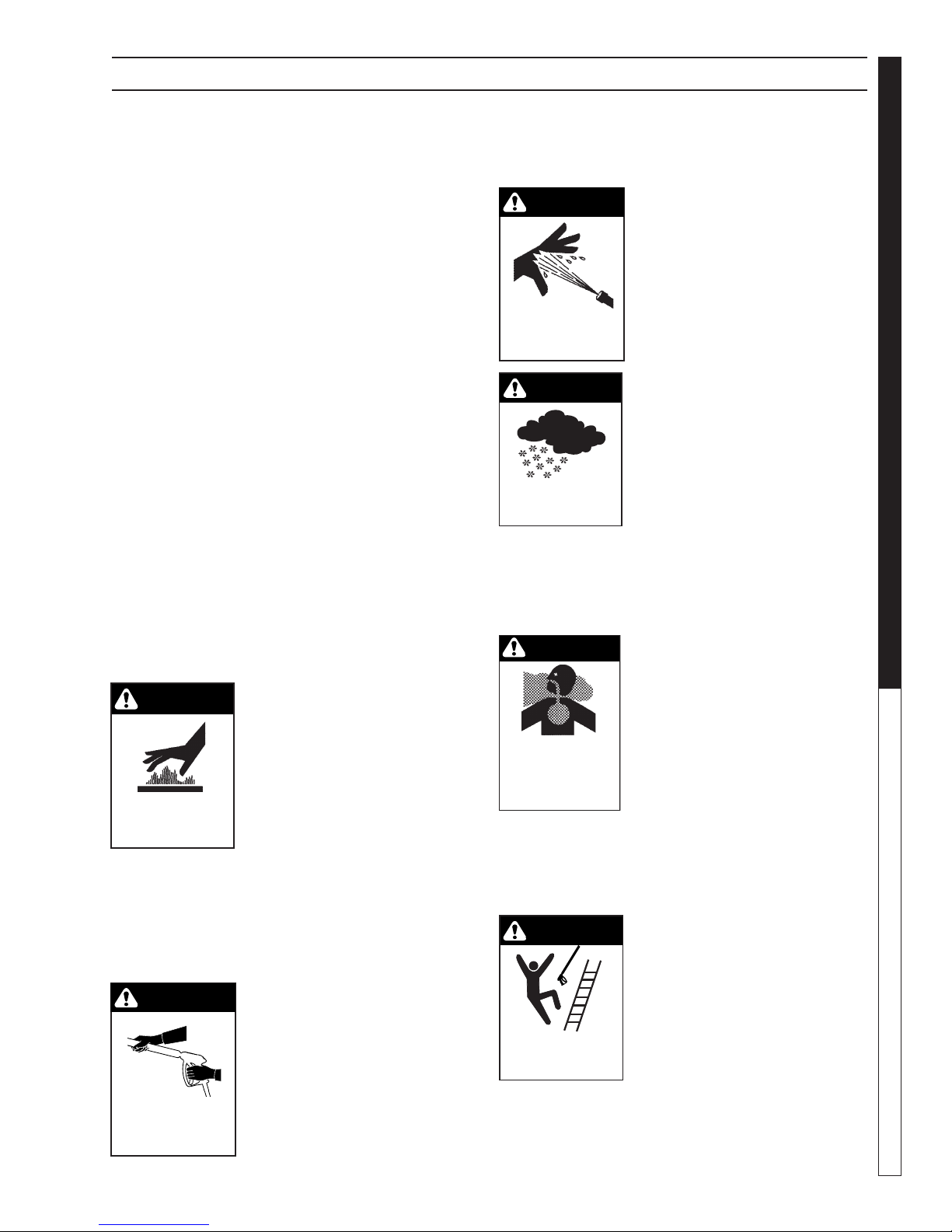

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

WARNING

WARNING: High pressure devel-

oped by these machines will

cause personal injury or equip-

ment damage. Keep clear of

nozzle. Use caution when oper-

ating. Do not direct discharge

stream at people, or severe in-

jury or death will result.

WARNING

PROTECT FROM

FREEZING

WARNING: Protect machine from

freezing.

14. To keep machine in best

operating conditions, it is

important you protect machine

from freezing.Failure to protect

machine from freezing

could cause malfunction of the

machine and result in death,

serious bodily injury, and/or property damage. Fol-

low storage instructions specified in this manual.

15. Inlet water must be clean fresh water and no hotter

then 90°F.

WARNING

RISK OF

ASPHYXIATION. USE

THIS PRODUCT ONLY IN

A WELL

VENTILATED AREA.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

16. Avoid installing machines

in small areas or near ex-

haust fans. Adequate ox-

ygen is needed for com-

bustion or dangerous car-

bon monoxide will result.

17. Manufacturer will not be liable

for any changes made to our standard machines

or any components not purchased from us.

18. The best insurance against an accident is precau-

tion and knowledge of the machine.

WARNING

RISK OF INJURY FROM

FALLS WHEN USING

LADDER.

WARNING: Be extremely careful

when using a ladder, scaffolding

or any other relatively unstable

location. The cleaning area

should have adequate slopes

and drainage to reduce the pos-

sibility of a fall due to slippery

surfaces.

19. Do not allow acids, caustic or abrasive fluids to pass

through the pump.

IMPORTANT SAFETY INFORMATION

WARNING: This product contains chemicals known

to the state of California to cause cancer and birth

defects or other reproductive harm. Operation of

this equipment may create sparks that can start

fires around dry vegetation. A spark arrestor may

be required. The operator should contact: Local

fire agencies for laws or regulations relating to fire

prevention requirements.

7. Allow engine to cool for 1-2 minutes before refu-

eling. If any fuel is spilled, make sure the area is

dry before testing the spark plug or starting the

engine. (Fire and/or explosion may occur if this is

not done.)

Gasoline engines on mobile or portable equipment

shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of

the dispensing point; and

d. with an allowance made for expansion of the

fuel should the equipment be exposed to a

higher ambient temperature.

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled

in a safe manner.

8. When in use , do not place machine near flammable

objects as the engine is hot.

9. Do not store or use gasoline near this machine.

WARNING

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas

of spray gun and wand. Do not

place hands or feet on non-insu-

lated areas of the pressure

washer.

10. Transport/Repair with fuel tank

EMPTY or with fuel shut-off valve

OFF.

11. To reduce the risk of injury, close supervision is

necessary when a machine is used near children.

Do not allow children to operate the pressure

washer. This machine must be attended during

operation.

TRIGGER GUN KICKS

BACK - HOLD WITH

BOTH HANDS

WARNING

WARNING: Grip cleaning wand

securely with both hands before

starting. Failure to do this could

result in injury from a whipping

wand.