CONTENTS

Contents ...........................................................................................................1

Safety Instruction .............................................................................................2

Product Overview ............................................................................................3

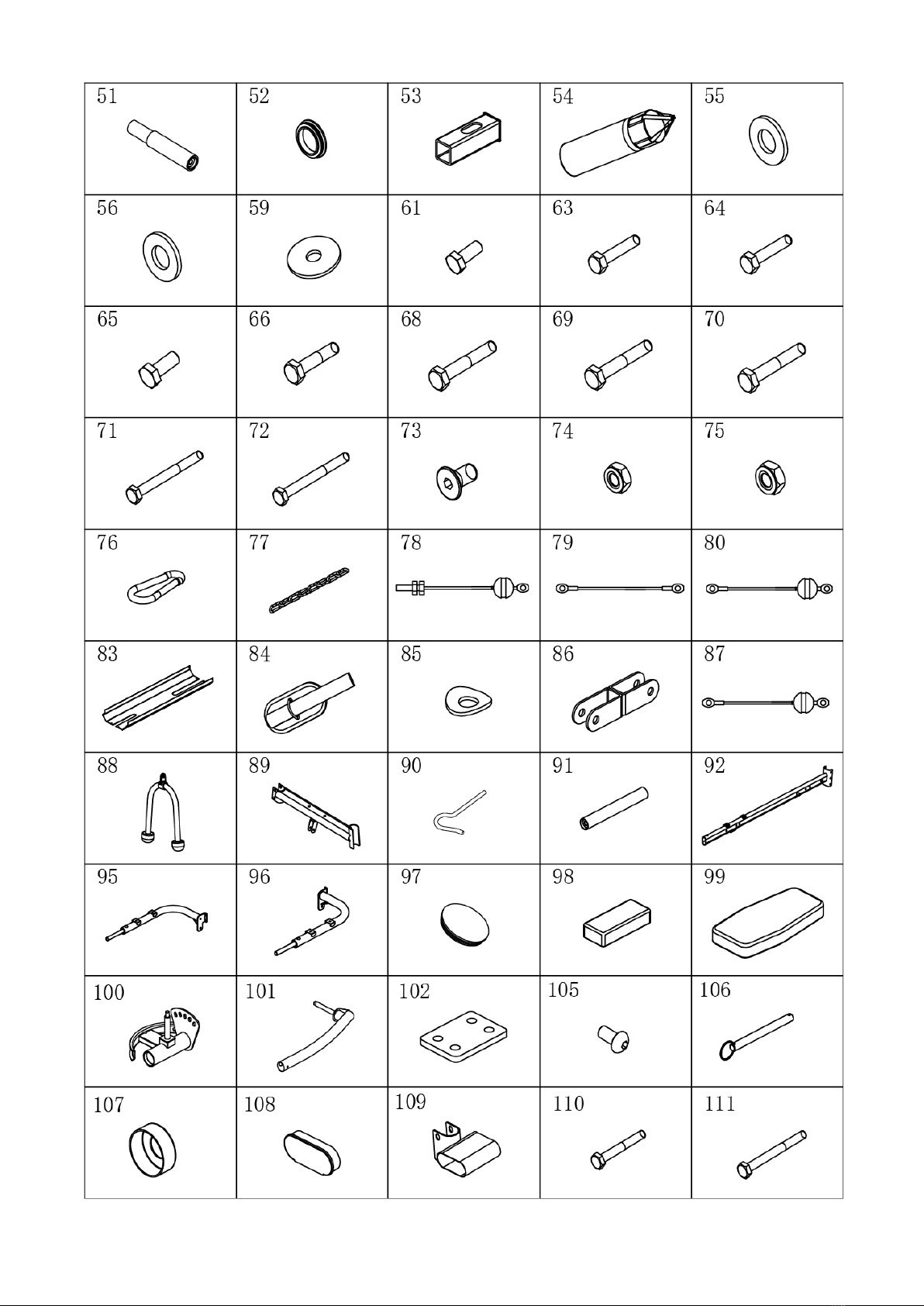

Parts List ..........................................................................................................4-9

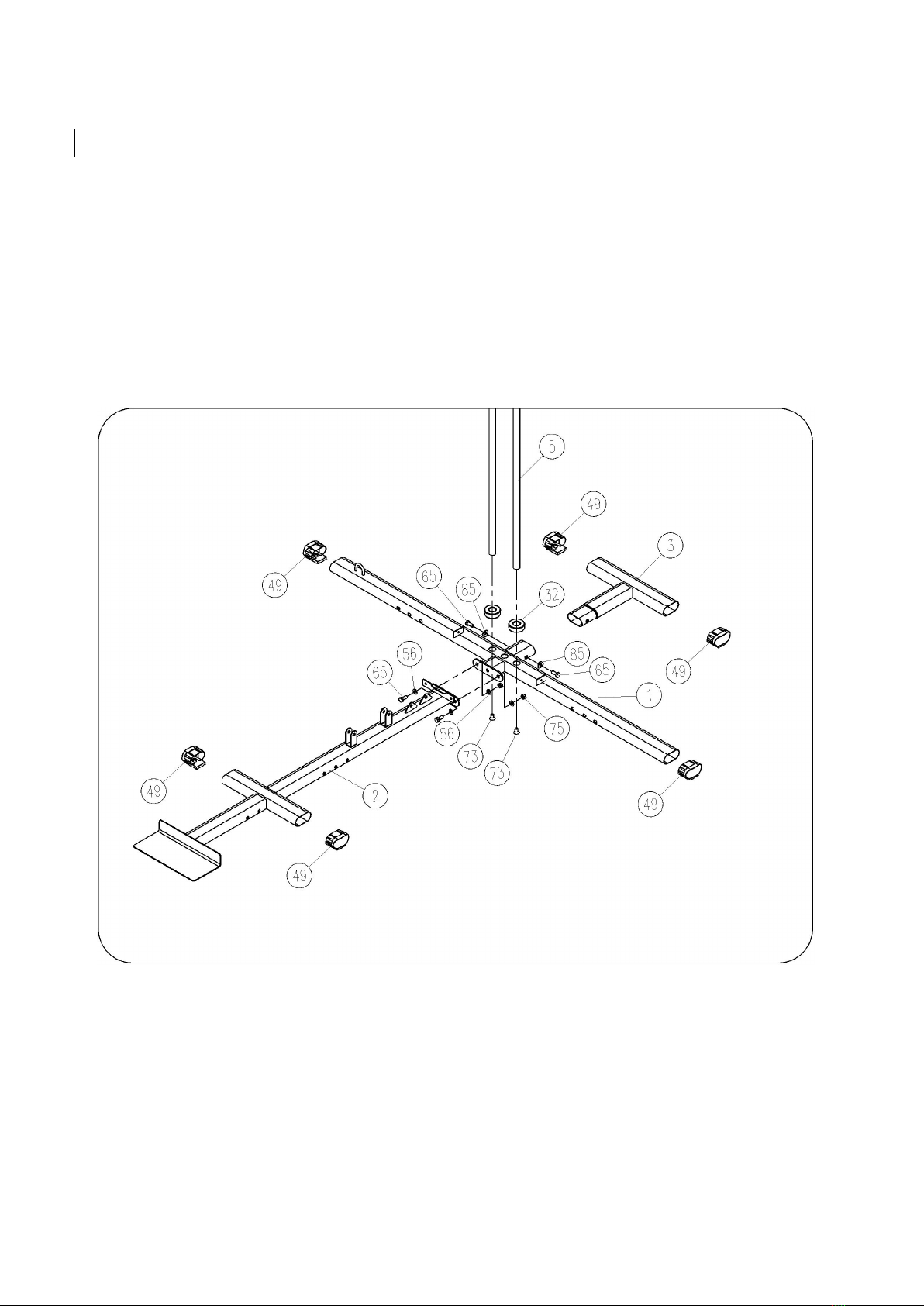

Assembly Instruction ....................................................................................10-28

Daily Care & Maintenance ............................................................................29

Friendly Reminder:

• Product or part pictures here may vary slightly from actual item due to model upgrades.

But they share similar assembly instruction. Please refer this manual as reference. Should you

have any question, please don’t hesitate to contact us for support. Thank you!

• Please check the packing details before assembly, if there is any missing part, contact after-sales

service department for support.

•

Please read all instructions carefully before using the product. Retain this user manual for future

reference.