III

Contents

Preface.............................................................................................. I

Manual Instruction ..................................................................... I

Target Reader............................................................................. I

Use the Manual........................................................................... I

Symbol Used .............................................................................. I

1 Safety Instructions.................................................................... 1

2 Product Introduction................................................................. 4

2.1 Power Pack application system Introduction ..................... 4

2.2 Product’s Introduction ........................................................ 5

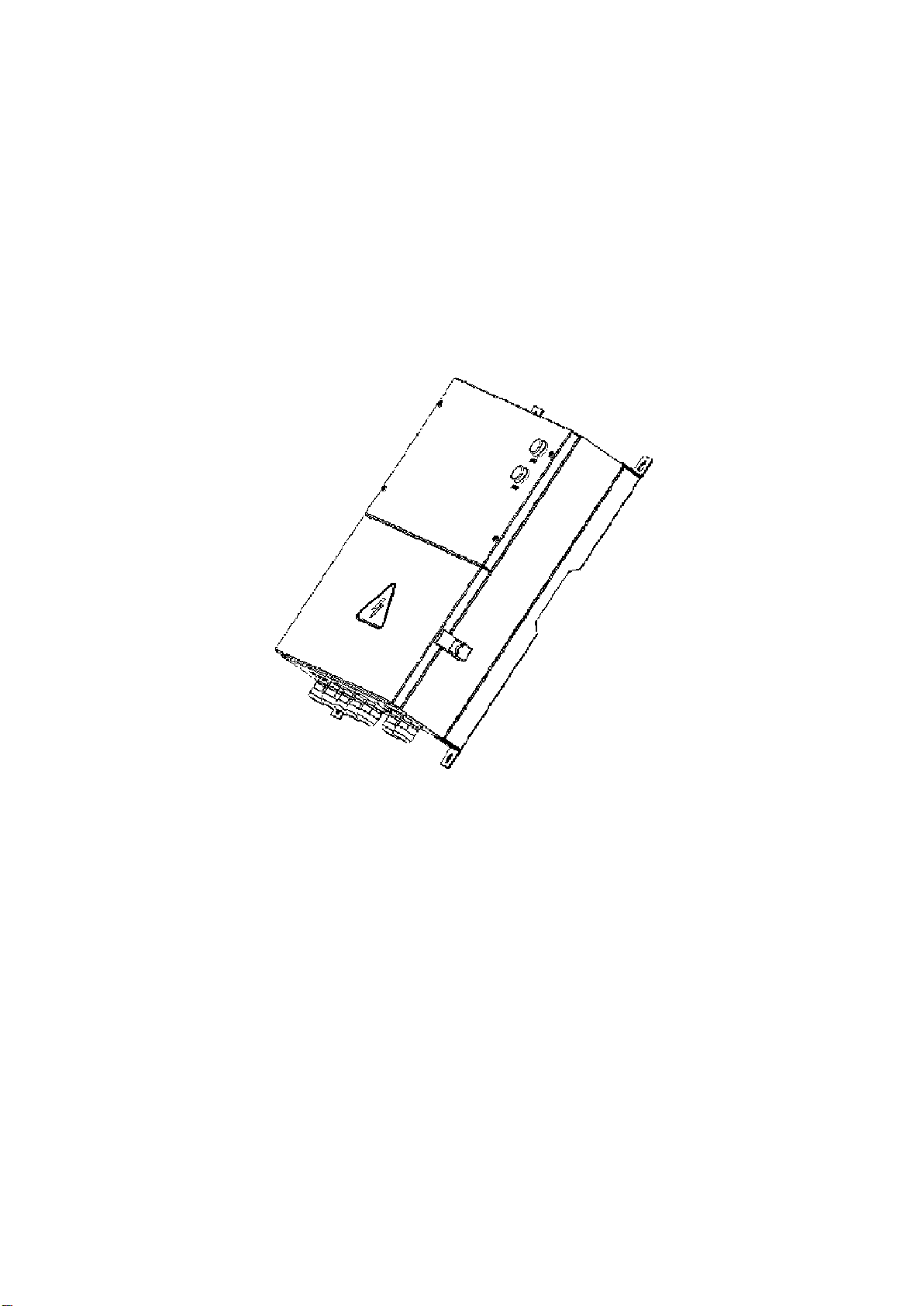

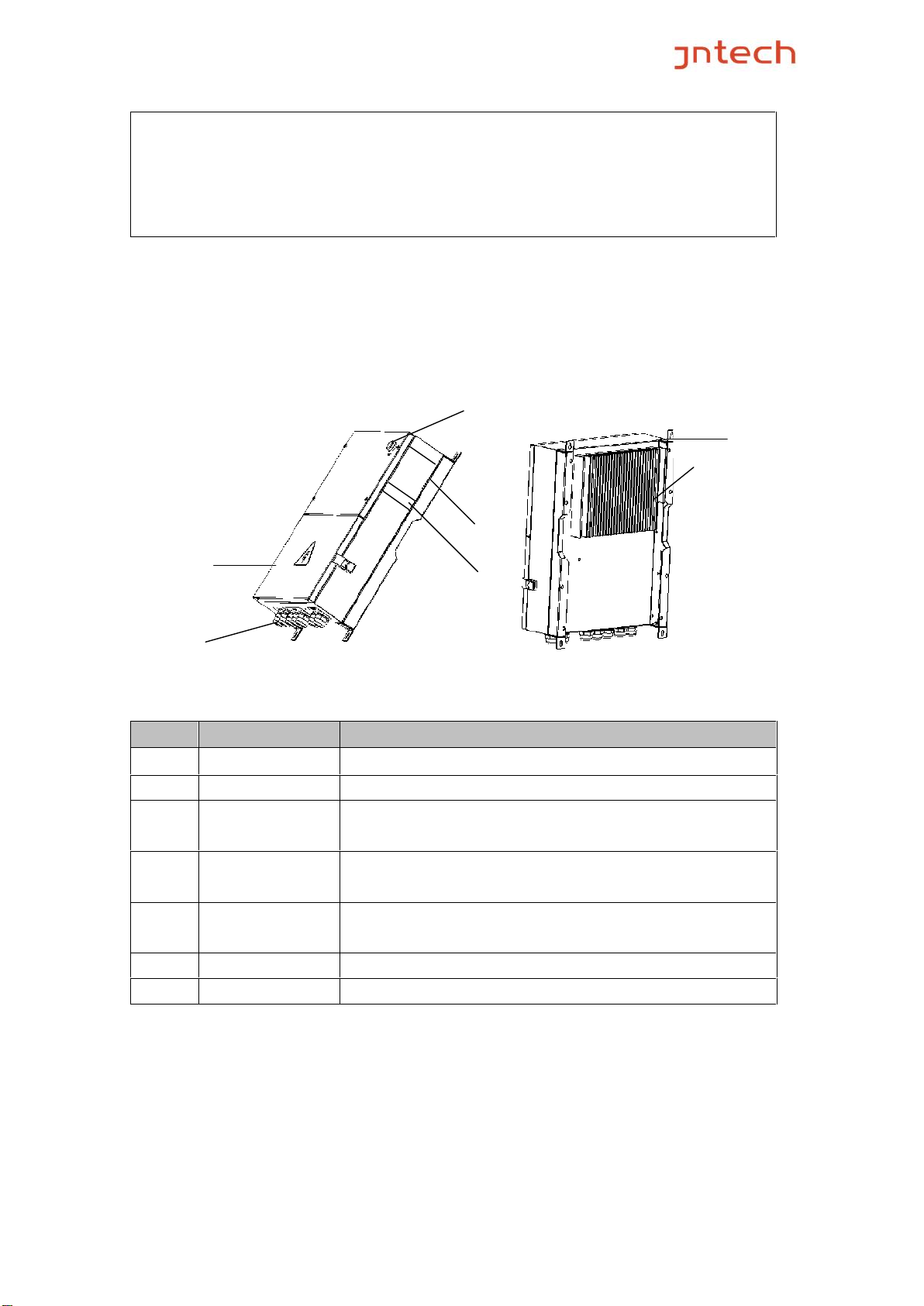

2.2.1 Appearance.................................................................. 5

2.2.2 Production Dimensions............................................... 6

2.2.3 Product Name.............................................................. 6

3 Power Pack Unpacking ............................................................. 7

3.1 Unpacking Check ................................................................ 7

3.2 Identify Power Pack............................................................. 8

4 Installation procedure............................................................... 9

4.1 Prepare Installation Tools ................................................... 9

4.2 Installation Site Required...................................................10

4.3 Installation Direction..........................................................10

4.4 Installation of Power Pack..................................................12

5 Electrical Connection...............................................................13

5.1 Power Pack Connecting Terminals.....................................13

5.2 Cable Selection ..................................................................16

5.3 Connector Disassembling ..................................................16

6 Power Pack Commissioning ....................................................17

6.1 Inspection before Commissioning .....................................17

6.2 First Commissioning of Power Pack ..................................19

7 Common troubleshooting and maintenance............................22

7.1 Troubleshooting .................................................................22

7.2 Maintenance .......................................................................23

7.3 Contact Customer Service .................................................23

8 Appendix..................................................................................24