Precautions

•Drain the moisture from the tank daily to help prevent corrosion.

•Pull the pressure relief valve ring daily to ensure proper function and clear possible obstructions.

•To provide proper ventilation for cooling, the compressor must be kept at least 12” (31 cm) from

the nearest wall, in a well-ventilated area.

•Fasten the compressor securely and release tank pressure before transporting.

•Protect the air hose and electric cordfrom damageand puncture. Inspect them weekly for weak or

worn spots, and replace if necessary.

•To reduce the risk of electric shock, do not expose to rain. Store indoors.

•Never operate the compressor if the power cord or plug is damaged. Take the

equipment to the nearest Authorized Service Center, to have it replaced.

Basic Air Compressor Components

Manual 58-7992 V 1.7– 8 Gallon compressor

2005-7-19

8

•Oil-less air compressors are factory lubricated for life and do not

require any further lubricated.

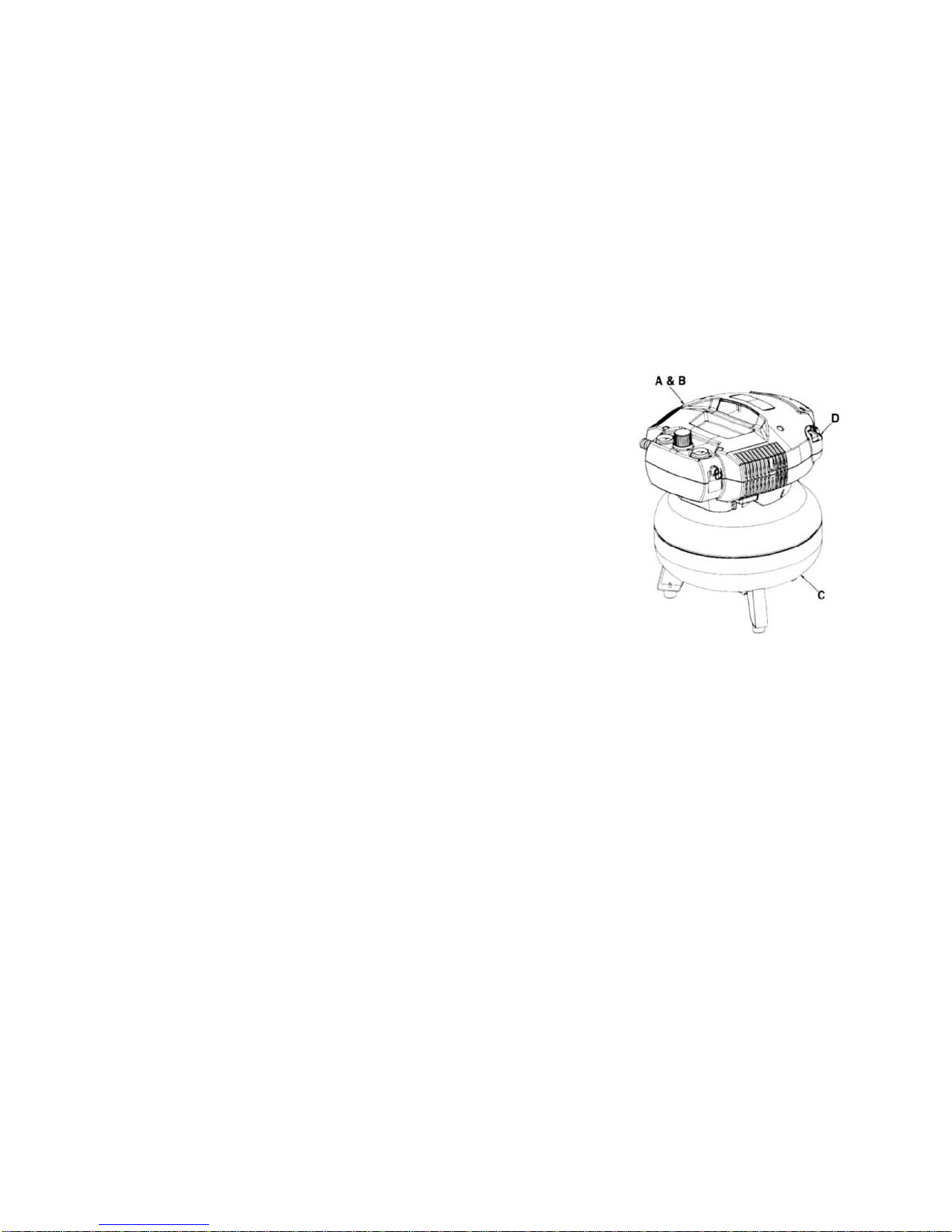

•The basic components of the air compressor are the electric motor,

pump, pressure switch, and tank. The electric motor (A) powers the

pump. The electric motor is equipped with an overload protector and

an automatic reset. If the motor becomes overheated, the overload

protector will shut it down to prevent damage to the motor. When the

motor cools sufficiently, it will automatically restart.

•The pump (B) compresses the air and discharges it into the tank.

•The tank (C) stores the compressed air.

•The pressure switch (D) shuts down the motor and relieves air

pressure in the pump and transfer tubwhen the air pressure in the tank

reaches the kick-out pressure. As compressed air is used and the

pressure level in the tank drops to the kick-in pressure, the pressure switch restarts the motor

automatically, without warning, and the pump resumes compressing air.

Fig 1

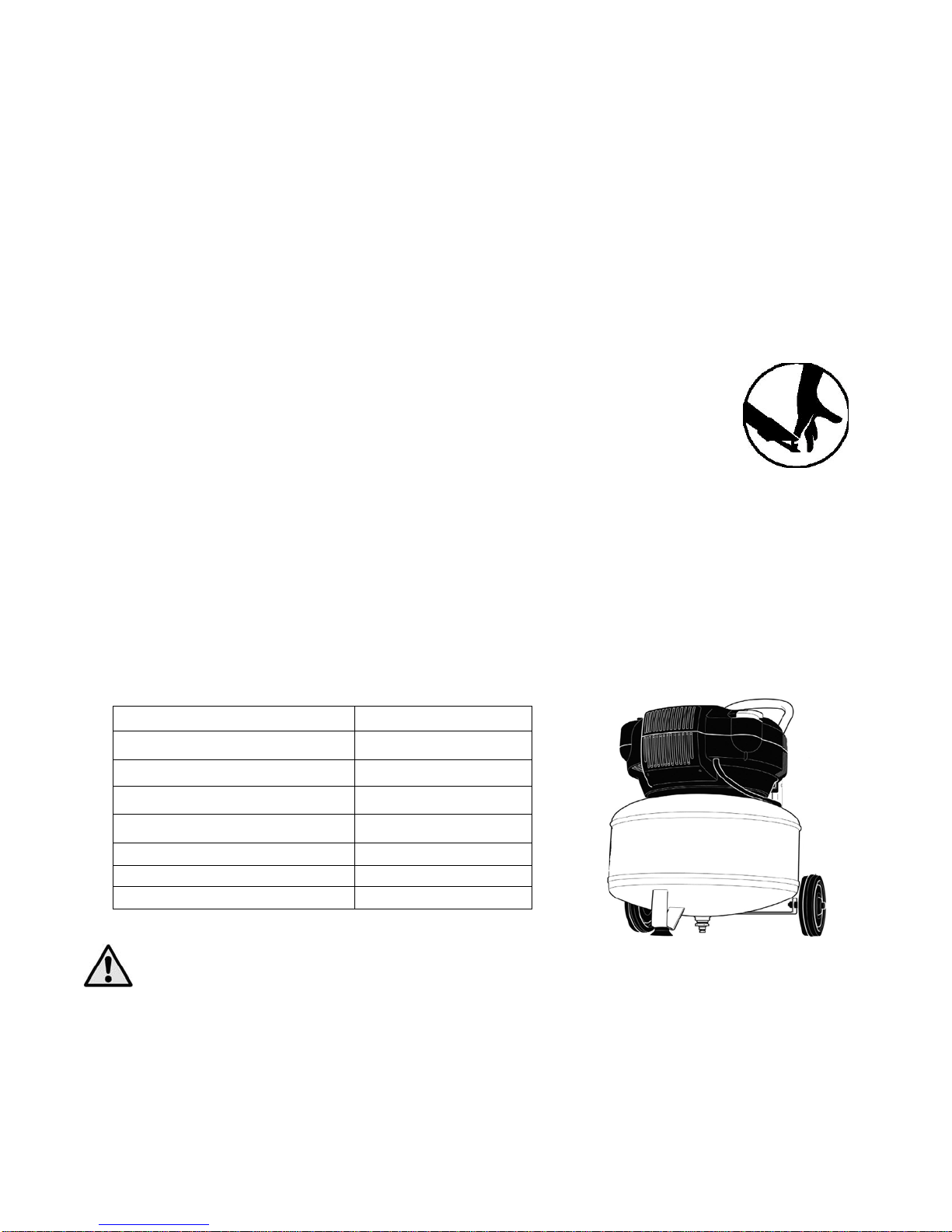

Assembling the Compressor

1.Unpack the air compressor. Inspect the unit for damage. If the unit has been

damaged in transit, contact the carrier and complete a damage claim. Do this

immediately as there is a time limit to damage claims. The carton should contain:

- Air compressor

- Operator and parts manuals

- Handle

- 3/8” x 25’ Air Hose (x1)

2.Tighten the handle into its position with the screws included.

3.Check the compressor’s specifications label to ensure that you have received the model ordered,

and that it has the required pressure rating for its intended use.

4.Locate the compressor according to the following guidelines:

a. Position the compressor near a grounded electrical outlet (see GROUNDING INSTRUCTIONS,

above).

b.The compressor must be at least 12”(31 cm) from any wall or obstruction, in a clean,

well-ventilated area, to ensure sufficient air flow and cooling.