8

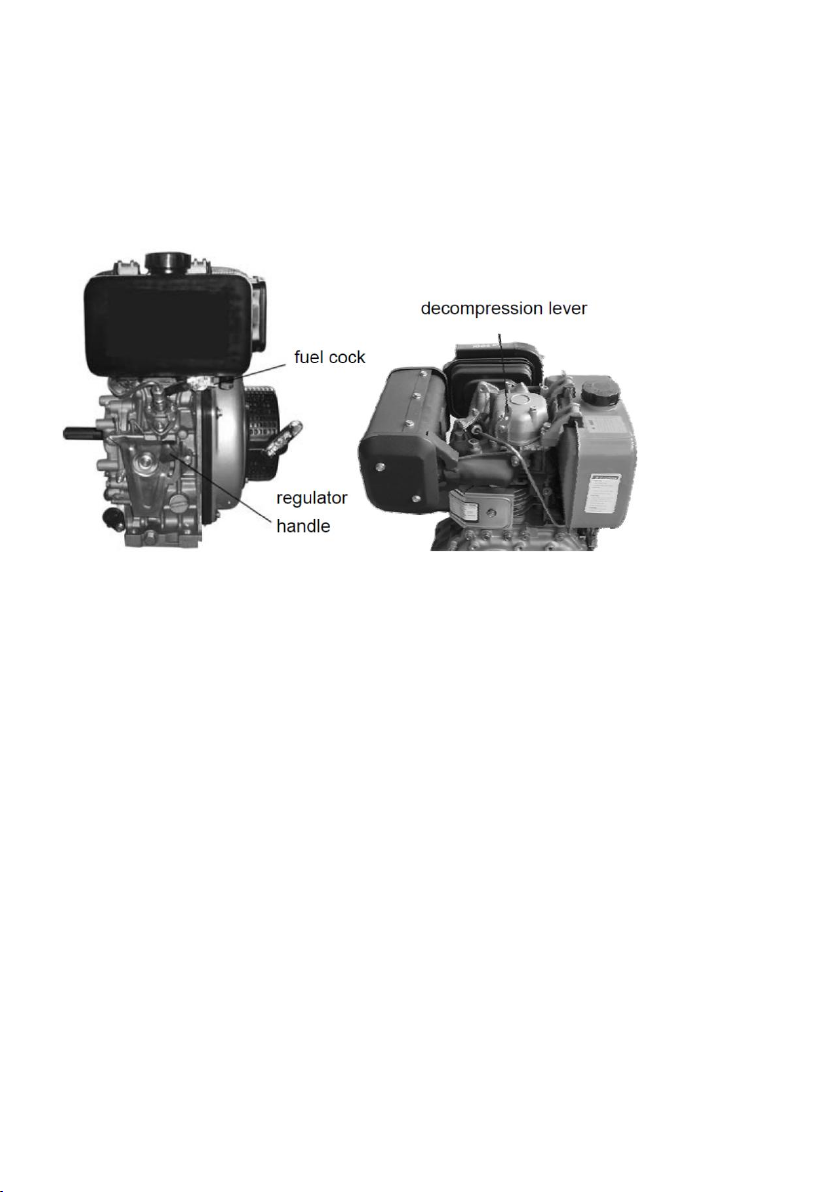

11. Set the fuel cock the “OFF” position.

12. Pull the recoil starter handles slowly, until you feel resistance. (At this

point, the decompression just begins and intake/exhaust valves are both

closed, thus the cylinder can be prevented from rust.)

13. Concerning the electric starting engine, directly turn the starting key to

“CLOSE”position.

●

The machine is best suited to the compaction of bituminous and granular

materials e.g. granular soils such as silt and clay are best compacted

using the impact force produced by a vibrating rammer.

●

Where possible the site should be graded and leveled before

commencing compaction.

●

Correct moisture content in soil is vital to proper compaction. Water acts

as a lubricant to help slide soil particles together. Too little moisture

means inadequate compaction; too much moisture leaves water-filled

voids that weaken the soil’s load-bearing ability.

●

Compaction of dry materials will be facilitated by moistening with a water

hose fitted with a sprinkler.

●

Excessive watering or water content will cause the machine to stall.

●

The optional water tank kit is recommended when the machine is used on

bituminous surfaces as the water film prevents a build up of material on

the underside of the plate.

●

The vibratory motion provides a self propelling action. Position the handle

at the opposite end of the machine to the vibrator.

●

For more information on starting and correct operating procedures of the

motor, refer to the motor operation manual supplied with the unit.

●

Increase the motor speed to the maximum setting using the hand throttle

lever, before commencing compacting.

●

The machine should be controlled by grasping the handle with both

hands and applying restraint to control the forward motion.

●

Steer the machine by moving the handle sideways to the right or left.

●

ALWAYS maintain good footing so that you do not slip and loose control

when starting or operating the machine.

●

If the optional water tank is fitted, the flow rate can be controlled by

adjusting the cock in the supply hose to sprinkler bar.

●

Inspect the water hose and its connections to ensure that they do not

leak.