5

Chapter I. Safety information and Warning

1. Training

a) Please read this manual carefully, and learn how to operate and use the tiller.

b) Don’t allow children and anyone without proper training to operate this tiller to avoid

injury.

c) Keep all persons (especial the kids) and pets away from the tilling working area.

2. Preparation

a) Move all the sundries away from the tiller working area.

b) Before engine starting, be sure the clutch is disengaged and the shift lever is in the neutral

position.

c) It is not allowed to operate the tiller without wearing proper coat. Wearing the antiskid

shoes can improve the stability on the slide surface.

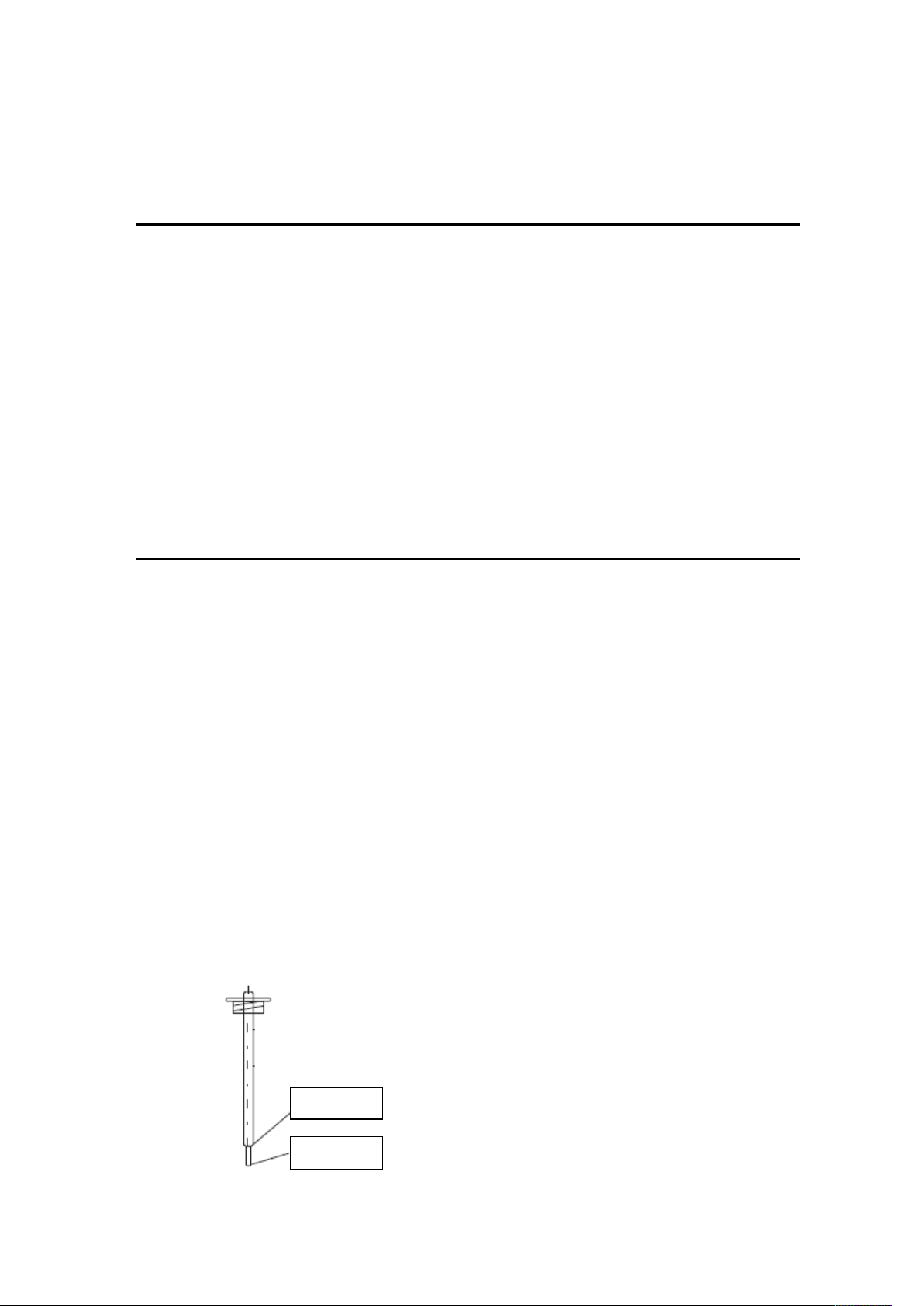

d) Be careful the fuel, it is extremely flammable.

1) Using the proper tank to store the fuel.

2) It is not allowed to refuel when engine is working or before engine cooled. Refueling the

lube oil into the tank is not permitted.

3) Refuel in a well-ventilated area with the engine stopped.

4) Before starting, tightening the fuel cap, and cleaning the spilled fuel.

e) When engine running, any adjustment is not allowed (except the special adjustment

recommended by manufacturer).

f) Please wear the safety glasses for any operation, such as: preparation, operation and

maintenance.

3. Operation

a) Keep your hands and feet away from the rotating parts while engine is running.

b) Be careful to operate on (or across) the cobble road, pavement or highroad. Be careful the

potential risk and traffic. Taking the passenger is not allowed.

c) Please stop the engine and check if the tiller be broken after striking sundries. It is not

allowed to start or operate before it is repaired if broken.

d) Attention the operation floor, avoid slipping down.

e) Any unusual vibration is the sign of fault should stop and inspect machine immediately.

f) Stop the engine, while leaving the operation position, cleaning the rotor, doing

maintenance, adjusting or checking the machine.

g) After using, should do the preventive measures, such as: disengage the power output, gear

in neutral position, engine off.

h) Before cleaning, maintenance and inspection, the engine should be off, and ensure all the

moving parts to be stopped.

i) Exhaust contains poisonous gas; don’t use the tiller in enclosure space.

j) No protective devices, no operation the tiller.

k) Keep away from the kids and pets.

l) To avoid over tilling depth, and over speed, cause the machine overload.

m) The tiller should not be run in high speed on the slippery road, be careful the back

situation when using backward gear.