3. MAIN PURPOSE AND FUNCTION

3.1 Purpose: It can be used for outside piling operation in farms, orchard fences

or barriers.

3.2 Function

3.2.1 It is a handheld gasoline pile driver which boasts light weight and low

discharge capacity.

3.2.2 The product conforms to design of man-machine engineering, reduces

working strength of the operator to the greatest extent, and boasts simple and

comfortable operation. The operator can achieve 360° all-around operation.

3.2.3 It can regulate impact energy and impact frequency and be applied to a

variety of piles ≥30mm or ≤120mm in diameter.

3.2.4 Advantage: Save the trouble of using heavy machines such as generator,

air compressor, and trucking-lorry.

3.2.5 The operating handle of the machine is rubber and plastic sponge handle

which can greatly reduce the recoil force of the machine. It’s installed with

two-way Damping Spring which makes the user more comfortable.

4. PREPARATION BEFORE USE

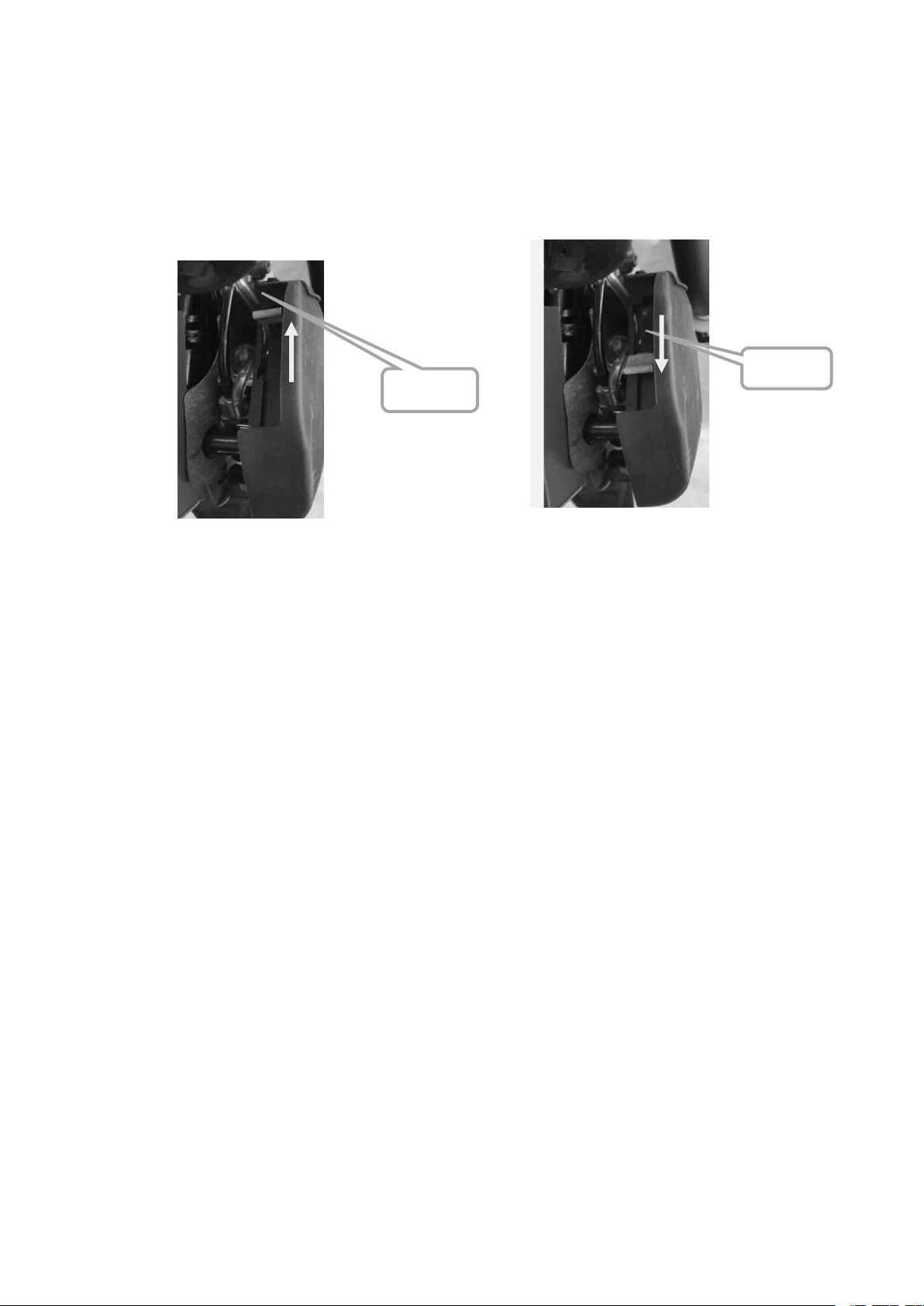

4.1Piling Socket

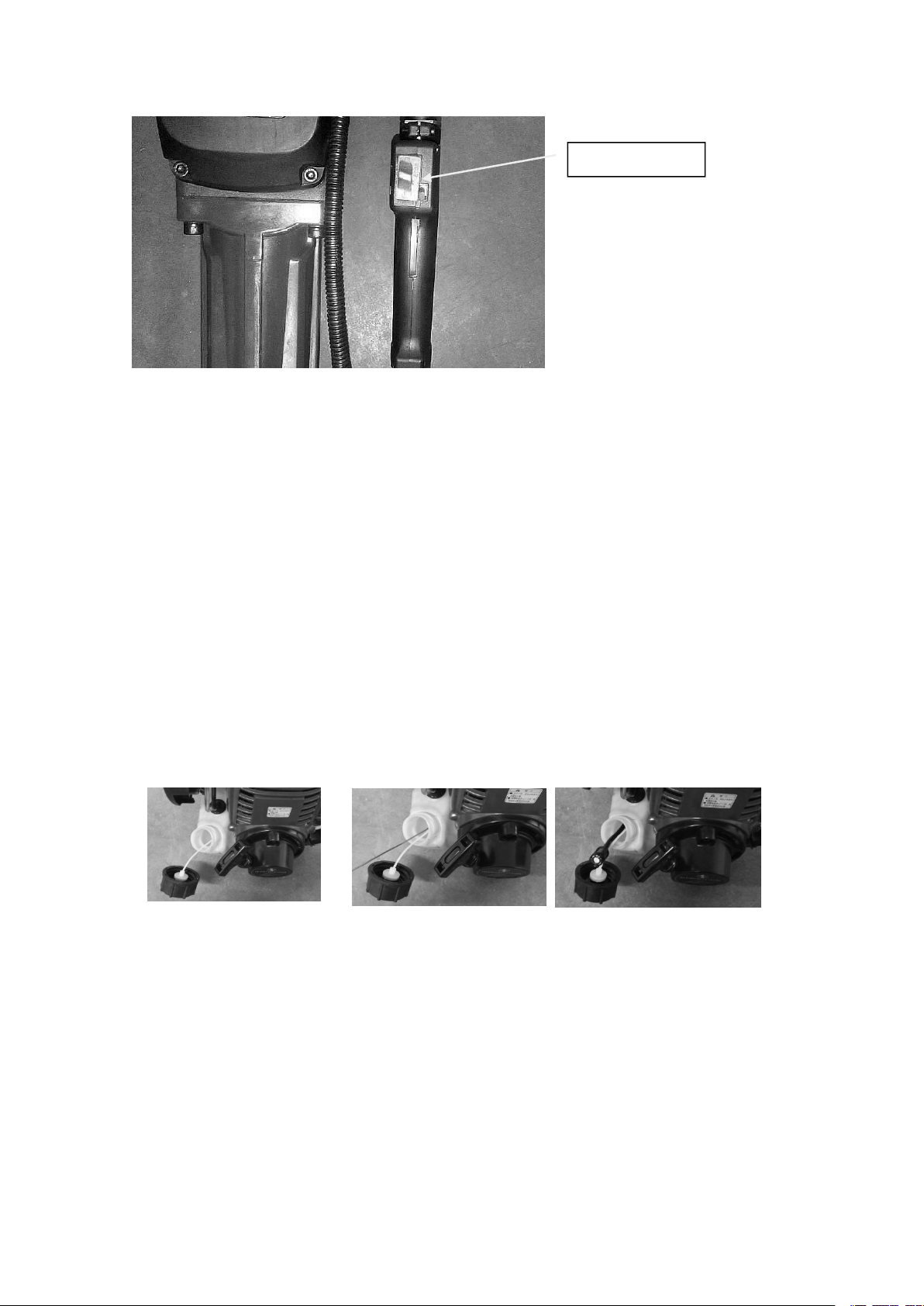

4.1.1 Install Piling Socket Re-tainer of specifications of Max:69mm, Max:100mm,

Max:120mm,which are suitable for the pile size. See Fig.3 for the knob.

Fig 3

4.2 Fuel

4.2.1 Use qualified gasoline above 90# and un-lead gasoline.

4.2.2 Fuel oil shall be added in an area where the gasoline engine is shut down

and away from open fires and well ventilated.

4.2.3 A freshly operated gasoline engine should be cooled to ambient

temperature before refueling

4.2.4 Do not add too much oil. The oil shall not exceed the neck of Fuel Tank

Filling Port. If fuel spills, wait until the fuel is removed or volatilizes completely

and then restart the machine.

4.2.5 After refueling, tighten the lid of Fuel tank.