Timbery BT100 User manual

Toothsetter/Guage

Safety, Operation, Limitations,

Maintenance & Parts Manual

BT100 rev. D.01

Safety is our #1 concern! Read and understand

all safety information and instructions before oper-

ating, setting up or maintaining this machine.

Form #220_en

!

2 D42doc102519 Table of Contest

Table of Contest Section-Page

SECTION 1 OVERVIEW 1-1

1.1 Toothsetter/Gauge (LTTSG) Introduction .............................................1-1

1.2 Deburring The Blade ..............................................................................1-2

SECTION 2 SETUP 2-1

2.1 Blade Support Installation ......................................................................2-2

2.2 Dial Indicator Setup................................................................................2-3

SECTION 3 OPERATION & MAINTENANCE 3-1

3.1 Blade Installation....................................................................................3-1

3.2 Toothsetter Adjustments.........................................................................3-2

3.3 Setting Point Adjustment........................................................................3-5

3.4 Toothsetter Operation.............................................................................3-7

3.5 Toothsetter Maintenance ........................................................................3-8

SECTION 4 REPLACEMENT PARTS 4-1

4.1 How To Use The Parts List ....................................................................4-1

4.2 Sample Assembly ...................................................................................4-1

4.3 Toothsetter, Complete ..........................................................................4-2

4.4 Toothsetter Parts List..............................................................................4-3

4.5 Toothsetter Stand Assembly...................................................................4-6

Overview

Toothsetter/Gauge (LTTSG) Introduction

Overview TSdoc102519 1-1

1

SECTION 1 OVERVIEW

1.1 Toothsetter/Gauge (LTTSG) Introduction

There are two steps to maintaining blades used on the Timbery sawmill. They should

ALWAYS be followed in this order:

1. Blade Sharpening

2. Toothsetting

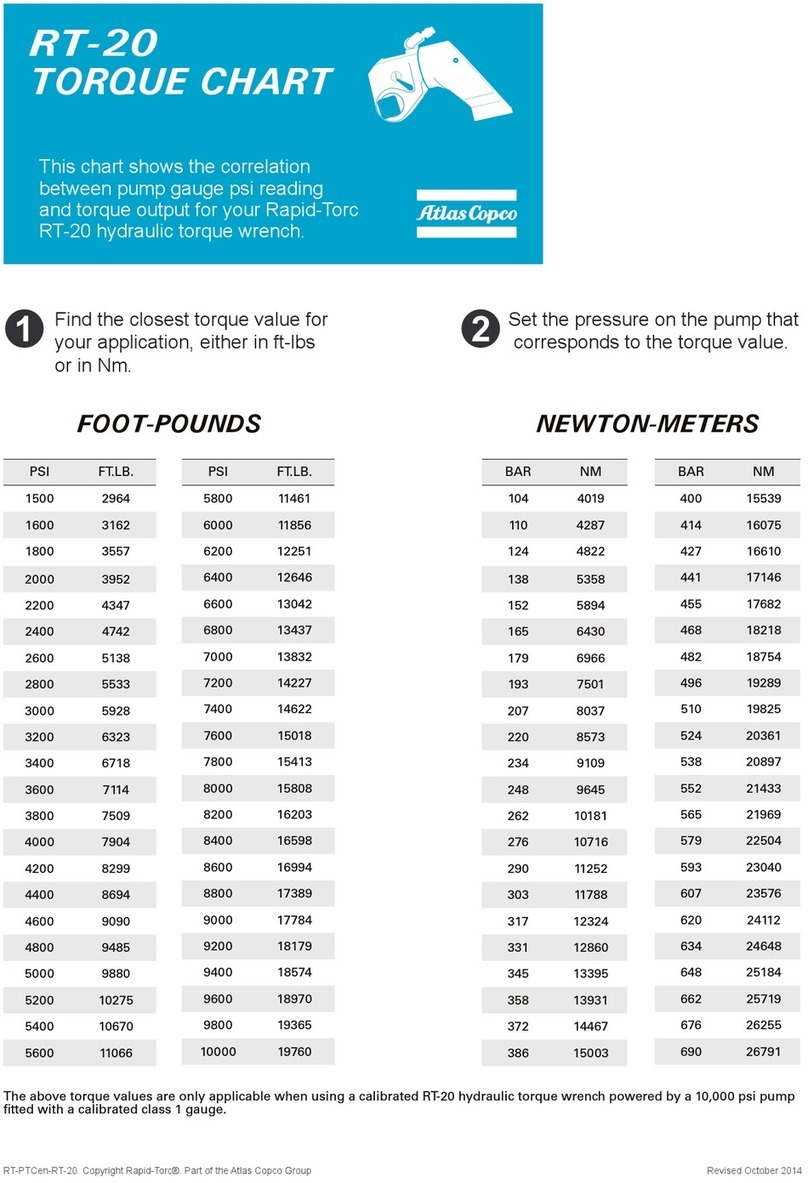

See Figure 1-1. The blades supplied by Timbery have a raker-style set in the teeth. If you

look at a blade from the top, you will see that the teeth are set (or bent out) in a repeating

sequence; straight, left and right. The teeth that are set left and right do the cutting. The

straight teeth (rakers) clear the cut of sawdust.

See Figure 1-2. As the blade is sharpened, the tip of the tooth recedes and the set

becomes smaller. Correct setting is one of the most important factors in the cutting ability

of a blade. Check used blades regularly to see if they need resetting.

The Toothsetter/Gauge (LTTSG) provided in the Blade Maintenance Package allows you

to accurately and evenly set the teeth of a bandsaw blade. The spring-loaded clamping

mechanism lets you position a tooth in front of the Gauge and clamp it in place. You can

then measure the set. The tooth is bent by clamping the blade further. This chapter

describes proper setup and operation of the toothsetter.

FIG. 1-1

FIG. 1-2

Set Left

Set Right

Raker

Set after

sharpening Original

Set

Overview

Deburring The Blade

1

1-2 TSdoc102519 Overview

1.2 Deburring The Blade

Sharpening leaves tiny metal burrs on the back side of the teeth. New blades also have

burrs. These burrs MUST be removed before the set is checked. If they are not removed,

they may cause the toothsetter to give false readings.

To remove burrs, take the blade from the Sharpener. Invert it, so that the inside of the

blade is facing out. Drag a stick of hardwood across the blade in the opposite direction

that the teeth cut. (Use the weld in the blade as a reference point for starting and stop-

ping.)

Cutting with the blade also removes burrs. If the blade you are about to set has been

used after sharpening, you will not need to deburr it. Clean the blade before removing

from the mill by running the Water Lube Option for 15 seconds. Remove the blade and

wipe dry with a rag to prevent rusting.

Setup

Setup doc102519 2-1

2

SECTION 2 SETUP

Mount the toothsetter to the stand. Use the mounting holes found in the base plate of the

setting fixture. Use the provided bolts (inserting the bolts down through the top of the

mounting plate), wing nuts and washers. Setup the toothsetter so that there is at least 32"

(81.0 cm) to the rear and to either side of the tool. This allows enough room for the blade

supports.

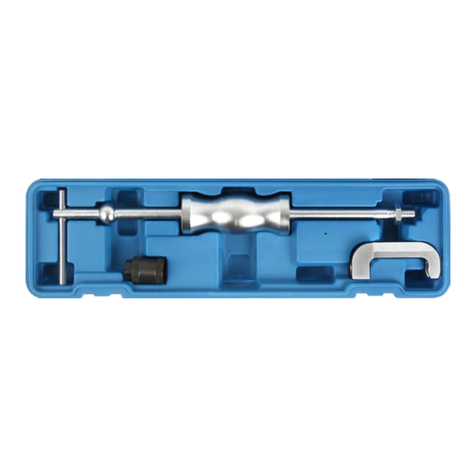

See Figure 2-1. The main components of the toothsetter are shown below. These parts

will be discussed in the following instructions.

FIG. 2-1

SM0038PL_B

Bla

d

e

S

u

p

p

o

r

t

T

u

b

e

s

(

3

)

D

i

a

l

I

n

d

i

c

a

t

o

r

R

i

g

h

t

I

n

d

e

x

P

a

w

l

Blad

e

R

e

s

t

Scre

w

s

(

2

)

Left Index Pawl

Gauge

Foot

Setting Point

Clamp

Adjustment

Nut

Clamping

Handle

Left Index Pawl

Blade Support Tubes (3)

Dial Indicator

Right Index Pawl

Blade Rest

Screws (2)

Clamping

Handle

Clamp

Adjustment

Nut

Setting Point

Gauge

Foot

Setup

Blade Support Installation

2

2-2 doc102519 Setup

2.1 Blade Support Installation

Attach the three blade support arms to the threaded mounting bar at the rear of the tooth-

setter.

See Figure 2-2. Assemble a blade support guide onto the end of each blade support arm.

Bolt from the hexed side of the guide assembly. Tighten the top bolts with the self-locking

nuts. Tighten the bottom bolts with the wing nuts.

The guides should be about 1" (2.5 cm) from the ends of the right and rear tubes and

about 2.5" (6.0 cm) from the end of the left tube. Final adjustments will be made later.

FIG. 2-2

B

l

a

d

e

s

u

p

p

o

r

t

a

r

m

Guide

assembly

SM0039PL

Guide

assembly

Blade support

arm

Setup

Dial Indicator Setup

Setup doc102519 2-3

2

2.2 Dial Indicator Setup

See Figure 2-3.

1. Back the setting point out of the way. Insert the hex key in the end of the setting con-

tact point shaft and turn counterclockwise until the setting contact point is behind the front

edge of the moving clamping plate.

2. Adjust the Dial Indicator. Clamp the gauge pin between the clamping plates. The pin

should be touching the center of the gauge foot.

The dial indicator should read 0. If the dial indicator does not show 0, loosen the dial lock

on the upper right side of the dial indicator. Rotate the dial indicator to 0 and retighten the

dial lock.

Now, remove the gauge pin from the toothsetter clamp. The dial indicator should now

read between -.001 and -.005.

FIG. 2-3

S

M

0

123PL_B

Use wrench to

back out setting

point

Clamp gauge pin

against

gauge foot Adjust Dial

to .000”

Use wrench to

back out set-

ting point

Clamp gauge pin

against gauge

foot

Adjust dial

to 0.000"

Setup

Dial Indicator Setup

2

2-4 doc102519 Setup

See Figure 2-4. If the dial indicator does not read between -.001 and -.005 with nothing

clamped, you will need to adjust the indicator mounting block:

3. Reclamp the gauge pin centered on the gauge foot.

4. Loosen the screw at the bottom of the indicator mounting block. Move the indicator

assembly back until the gauge foot does not touch the gauge pin.

5. Move the indicator assembly forward so the gauge foot touches the gauge pin and the

gauge needle moves .001 - .005. Retighten the mounting block screw. Make sure the

mounting block remains flat against the toothsetter base plate.

6. Rotate the dial face until the gauge reads zero.

7. Unclamp the gauge pin. The indicator should now read -.001 to -.005. If not, repeat steps

3-6.

FIG. 2-4

SM0124C

Loosen screw to move

dial indicator forward

or backward

Operation & Maintenance

Blade Installation

Operation & Maintenance TSdoc102519 3-1

3

SECTION 3 OPERATION & MAINTENANCE

Once the toothsetter alignments have been checked and adjustments have been made,

you are ready to measure and set blades.

Sharpening removes metal from the face of the tooth. This eventually reduces the set to a

point where the blade will not cut very well. Set should not vary more than (±)0.001 from

one tooth to the next.

The following steps will take you through operation of the toothsetter.

Note: Refer to the Tru•Sharp™ Blade Handbook for recommended set specifications for

your sawing application.

3.1 Blade Installation

1. Clean the blade and deburr before putting it in the toothsetter. Otherwise, sap

buildup on the blade or tooth will give false set readings. Metal burrs created by sharpen-

ing also will cause false readings.

2. Mount the blade in the toothsetter. Place blade between the clamping plates and on

the three guide assemblies.

NOTE: You will need to move both the left and right index pawl assemblies down and out

of the way. These will be adjusted later.

3. Set the clamping assembly to hold the blade. The clamp is set at the factory to lock

the blade firmly as the handle throws over. If the handle is difficult to push forward or

throws over before locking the blade, adjust the clamp nut.

Operation & Maintenance

Toothsetter Adjustments

3

3-2 TSdoc102519 Operation & Maintenance

See Figure 3-1.Loosen the clamp adjustment nut. Turn the clamp nut and set the dis-

tance between the clamp plates. After the clamp is adjusted properly, tighten the clamp

adjustment nut.

3.2 Toothsetter Adjustments

FIG. 3-1

SM0040PL_B

Clamp Adjustment

Nut

Clamp Adjustment

Nut

Operation & Maintenance

Toothsetter Adjustments

Operation & Maintenance TSdoc102519 3-3

3

See Figure 3-2.

1. Adjust the blade rest screws. Rest the blade evenly on the two blade rest bolts on each

side of the clamp. Adjust the rest screws until the gullet of the blade lies just above the top

of the clamp plates. (Deburring will remove burrs from the back side of the teeth, but may

not remove burrs from the gullet area. Keeping the gullet out of the clamp assembly helps

to assure accurate readings.)

2. Make final adjustments to blade support arms and guide assemblies. Adjust to

assure the blade travels smoothly. Blade should rest on rear guide, but should not touch

the bottom of either side guide assembly.

3. Adjust the setting contact point. Position the blade so the gauge foot is in between two

teeth. Use the hex key to bring the setting contact point towards the gauge foot until the

dial indicator reads 15-20 thousandths.

FIG. 3-2

SM0299B

Blade Rest

Bolt

Blade Rest

Bolt

Operation & Maintenance

Toothsetter Adjustments

3

3-4 TSdoc102519 Operation & Maintenance

4. Position the blade. Turn the blade to bring a weld into the clamping/setting assembly.

Use the weld as a reference point for starting and stopping. Start with the first tooth to the

right (See NOTE) of the weld that has been set back toward the dial indicator.

NOTE: The toothsetter sets and measures the teeth which are set away from the opera-

tor and towards the dial indicator. To measure teeth set in the opposite direction, invert

the blade and insert it in the toothsetter.

Operation & Maintenance

Setting Point Adjustment

Operation & Maintenance TSdoc102519 3-5

3

See Figure 3-3.Position that tooth in front of the gauge foot so the its edge is aligned with

the center of the setting point.

5. The index pawls are factory-set for Tru•Sharp™ blades with 7/8" tooth spacing.

Check the right (or left if the blade is inverted) side index pawl is firmly against the tooth

two teeth to the right (or left) of the one being set. To adjust, loosen the index pawl screw

with the hex key provided and move the pawl tight against the tooth. Retighten the screw.

3.3 Setting Point Adjustment

If you are setting a blade with a 10.30 or 13.29 profile, install an appropriate washer

spacer to the moving blade clamp assembly before beginning the setting operation

(see the figures below). It is not necessary to use a washer spacer when blades with 9.29

profiles are set. Each toothsetter is equipped with two washer spacers for adjusting the

setting point: a washer marked “10.30” (part No. 094312) and a washer marked “13.29”

(part No. 094313). Use the "10.30" washer for standard, 10.30 blade profiles and the

"13.29" washer for 13.29 blade profiles. The "10.30" washers are factory-installed in the

FIG. 3-3

Edge of tooth aligned with

center of setting point

Operation & Maintenance

Setting Point Adjustment

3

3-6 TSdoc102519 Operation & Maintenance

machine.

FIG. 3-4

SM0308PL_B

Operation & Maintenance

Toothsetter Operation

Operation & Maintenance TSdoc102519 3-7

3

3.4 Toothsetter Operation

1. Set the blade. Measure set by clamping the blade between the back clamping plate and

the spring-loaded pins on the front clamping plate. Remember set should not vary more

than (±)0.001 from one tooth to the next.

To add set, clamp in further on the blade. This brings the setting contact point against the

tooth. The amount you will need to bend the tooth forward to get the desired set will vary.

Recheck set and adjust as needed.

NOTE: If the clamp locks before you have added enough set, adjust the setting contact

point in. DO NOT adjust the clamp nut.

To decrease set, bend the tooth back with the slot in the correction tool provided.

Recheck set and adjust as needed.

Slide the blade to the right (or left) until the third tooth from the one just set comes in front

FIG. 3-5

SM0309PL_B

Operation & Maintenance

Toothsetter Maintenance

3

3-8 TSdoc102519 Operation & Maintenance

of the gauge foot. Push this tooth firmly against the index pawl. Check set by lightly push-

ing the handle until the spring-loaded pins in the clamping assembly push the blade

against the back plate. Read the dial indicator. Adjust set as necessary (see above).

Check every third tooth until you reach the weld.

2. Set the opposite side of blade. Remove the blade and invert it. Put the blade back in

the toothsetter with the teeth pointing to the left. Repeat the above steps to set the teeth

using the left side index pawl assembly. The amount that you must bend the teeth to end

up with the same set as the first side of the blade probably will differ.

3. Remove the blade. Take the blade out of the toothsetter. Be sure the blade is turned to

the correct side before putting it on the sawmill.

3.5 Toothsetter Maintenance

Keep the toothsetter clean.

Keep all moving parts lubricated with a light penetrating oil.

Remove the clamping assembly occasionally and clean any debris that may have

collected between the clamping plates.

Replacement Parts

How To Use The Parts List

Replacement Parts TS92doc102519 4-1

4

SECTION 4 REPLACEMENT PARTS

4.1 How To Use The Parts List

Use the index above to locate the assembly that contains the part you need.

Go to the appropriate section and locate the part in the illustration.

Use the number pointing to the part to locate the correct part number and

description in the table.

Parts shown indented under another part are included with that part.

Parts marked with a diamond () are only available in the assembly listed above the

part.

See the sample table below. Sample Part #A01111 includes part F02222-2 and

subassembly A03333. Subassembly A03333 includes part S04444-4 and subassembly

K05555. The diamond () indicates that S04444-4 is not available except in subassembly

A03333. Subassembly K05555 includes parts M06666 and F07777-77. The diamond ()

indicates M06666 is not available except in subassembly K05555.

To Order Parts:

From Europe call our European Headquarters and Manufacturing Facility in Kolo,

Poland at +48-63-2626047. From other international locations, contact the Timbery

distributor in your area for parts.

4.2 Sample Assembly

REF DESCRIPTION ( Indicates Parts Available In Assemblies Only) PART # QTY.

Sample Assembly, Complete (Includes All Indented Parts Below) A01111 1

4Sample Part F02222-22 1

Sample Subassembly (Includes All Indented Parts Below) A03333 1

5Sample Part ( Indicates Part Is Only Available With A03333) S04444-4 1

Sample Subassembly (Includes All Indented Parts Below) K05555 1

6Sample Part ( Indicates Part Is Only Available With K05555) M06666 2

7Sample Part F07777-77 1

Replacement Parts

Toothsetter, Complete

4

4-2 TS92doc102519 Replacement Parts

4.3 Toothsetter, Complete

REF. DESCRIPTION ( Indicates Parts Available In Assemblies Only) PART NUMBER QTY.

Toothsetter, Complete BMT100 / BT100

Toothsetter, Complete 087557 1

1Toothsetter Assembly, Boxed, w/o Stand & Arms 087765 1

2Arm Assembly, Blade Support 087766 1

3Stand Assembly, Toothsetter 087767 1

1

3

2

Replacement Parts

Toothsetter Parts List

Replacement Parts TS92doc102519 4-3

4

4.4 Toothsetter Parts List

REF. DESCRIPTION ( Indicates Parts Available In Assemblies Only) PART NUMBER QTY.

Arm Assembly, Blade Support 087766 1

Blade Support Assembly, Replacement A10617 1

1Tube, Blade Support Long 087519-1 1

2Tube, Blade Support Short 087670-1 2

3Guide WO/Post, Blade Support S10612 3

4Guide W/Post, Blade Support S10611 3

5Bolt, 1/4-20 X 1 1/2" Hex Head Grade 2 F05005-5 6

6Nut, 1/4-20 Self-Locking F05010-9 3

7Nut, 1/4-20 Wing F05010-13 3

TOOTHSETTER ASSEMBLY, BOXED 087765 1

TOOTHSETTER ASSEMBLY 087502 1

8Bracket, moving clamp 096863-1 1

9Bracket, Blade Support Tube 092914-1 1

SM0115P2e

22

18

24

2

62

63

64

42

43

44

45

46

47

49

50

51

52 53

54

55

60 61

12

15

56

26

27

28

29

10

11

9

1

8

30

31

37

37

39

38

39

39

48

58

59

16

18

32

33

34

35

26

20

17 19

21

13

40

41

57

4

5

6

3

7

14

36

23

65

25

66

67

Replacement Parts

Toothsetter Parts List

4

4-4 TS92doc102519 Replacement Parts

10 Pin, Toothsetter Alignment F05012-60 1

11 Tool, Set Correction 087862-1 1

12 Bolt, M10 x 35 8.8 Hex Head Full Thread Zinc F81003-17 2

13 Washer, 10.5 Flat Zinc F81055-1 4

14 Plate, Toothsetter Fixed Clamp Zinc 087503-1 1

15 Base Weldment 087504-1 1

16 Plate, Moving Clamp 096862-1 1

17 Nut, M8 Hexagon, Grade 5.8 Free Zinc F81032-1 1

18 Washer, 6.4 Flat Zinc F81053-1 8

19 Screw, M8x40-45H Hex Socket Head F81002-52 1

20 Nut, M5-8 DIN985 Zinc F81030-2 2

21 Screw, M10 x 25 8.8 Hex Socket Head Cap F81003-32 1

22 Bolt, 6/M5x25 12.9 ISO7379 Shoulder F81001-19 4

23 Plate, Clamp Wear 087463 1

24 Spring, 1/2" x 1" Red Die 004750 4

25 Nut, M5-8 Hex Zinc F81030-1 2

26 Washer, 5.3 Flat F81052-1 6

27 Pin, 3 x 20 Roll Zinc F81044-5 2

Bolt, Complete Special 087513 2

28 Shaft, Pawl Adjustment 087512-1 2

29 Block, Pawl Adjustment 087509-1 2

30 Pawl, Index 087510-1 2

31 Pin, 5 x 26 Roll Zinc F81044-2 2

32 Block, Moving Blade Clamp Upper Zinc-plated 092912-1 1

33 Washer, Zinc-plated Spacer "10.30" Profile

Washer, Zinc-plated Spacer "13.29" Profile

094312

094313

1

1

34 Bolt, M8x35 -8.8 Hex Head Full Thread Zinc F81002-13 2

35 Washer, 8.4 Flat Zinc F81054-1 2

36 Screw, M6x20-10.9 Fe/Zn5 DIN-7991 F81001-17 2

37 Screw, M6 x 16 8.8 Hex Socket Head Cap Zinc F81001-21 2

38 Screw, M6 x 20 8.8 Hex Socket Head Cap Zinc F81001-22 6

39 Washer, 6.4 Flat Zinc F81053-1 4

40 Bolt, M6x80-8.8 Hex Head Full Thread Zinc F81001-61 2

41 Spring, LC-045E-12 P04734 2

Clamp Assembly, Toothsetter 087438

42 Washer, Z 6.1 Split lock Zinc F81053-3 4

43 Pin, 5 x 16 Roll Zinc F81044-3 2

44 Bushing, Toothsetter 087442-1 1

45 Nut, M12 x 1.25-8 Hex Zinc F81034-8 1

46 Bushing, Zinc Toothsetter 087440-1 1

47 Bearing, 51103 FLT Thrust Ball 086675 1

48 Housing, Toothsetter Bearing 087439-1 1

49 Ring, 17 Interior Retaining F81090-21 1

50 Ring, 32W Interior Retaining F81090-5 1

51 Bolt, Threaded Push Pull 087441-1 1

52 Bolt, M8x20-5.8 Hex Head Full Thread Zinc F81002-1 1

Handle Assembly, Toothsetter Clamp

Table of contents