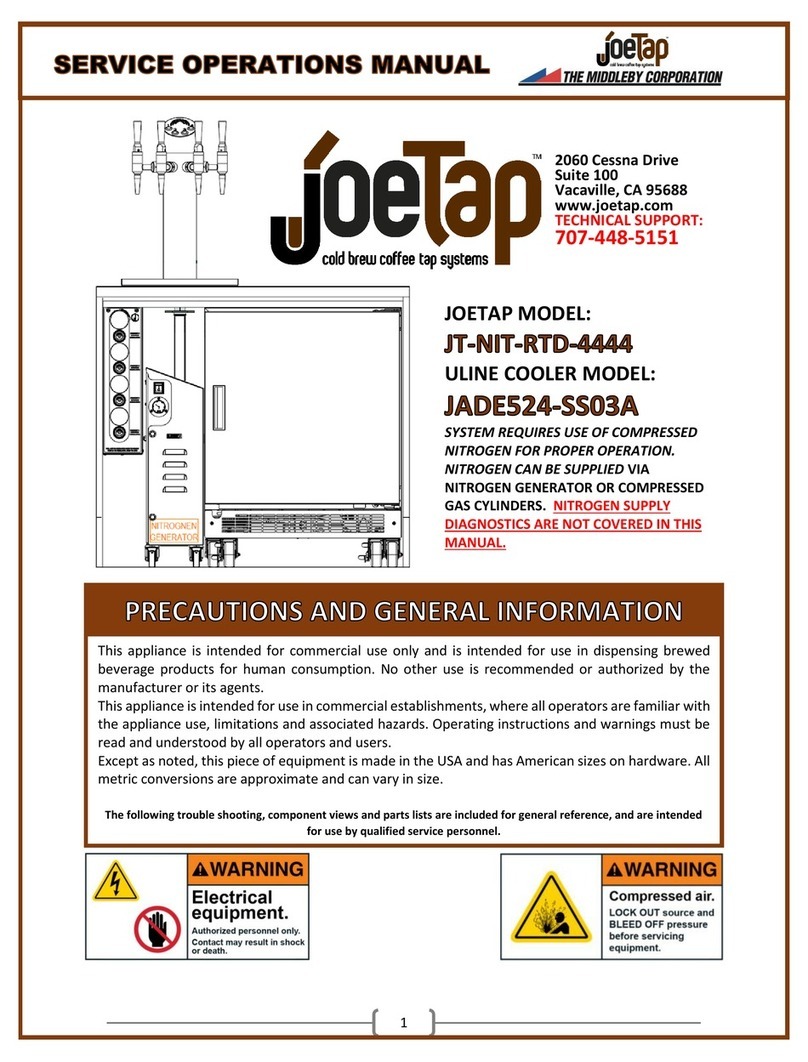

JoeTap JADE524-SS03A User manual

This appliance is intended for use in

commercial establishments, where all

operators are familiar with the appliance

use, limitations and associated hazards.

Operating instructions and warnings

must be read and understood by all

operators and users.

2060 Cessna Drive

Suite 100

Vacaville, CA 95688

www.joetap.com

TECHNICAL SUPPORT:

707-448-5151

JOETAP MODEL:

ULINE COOLER MODEL:

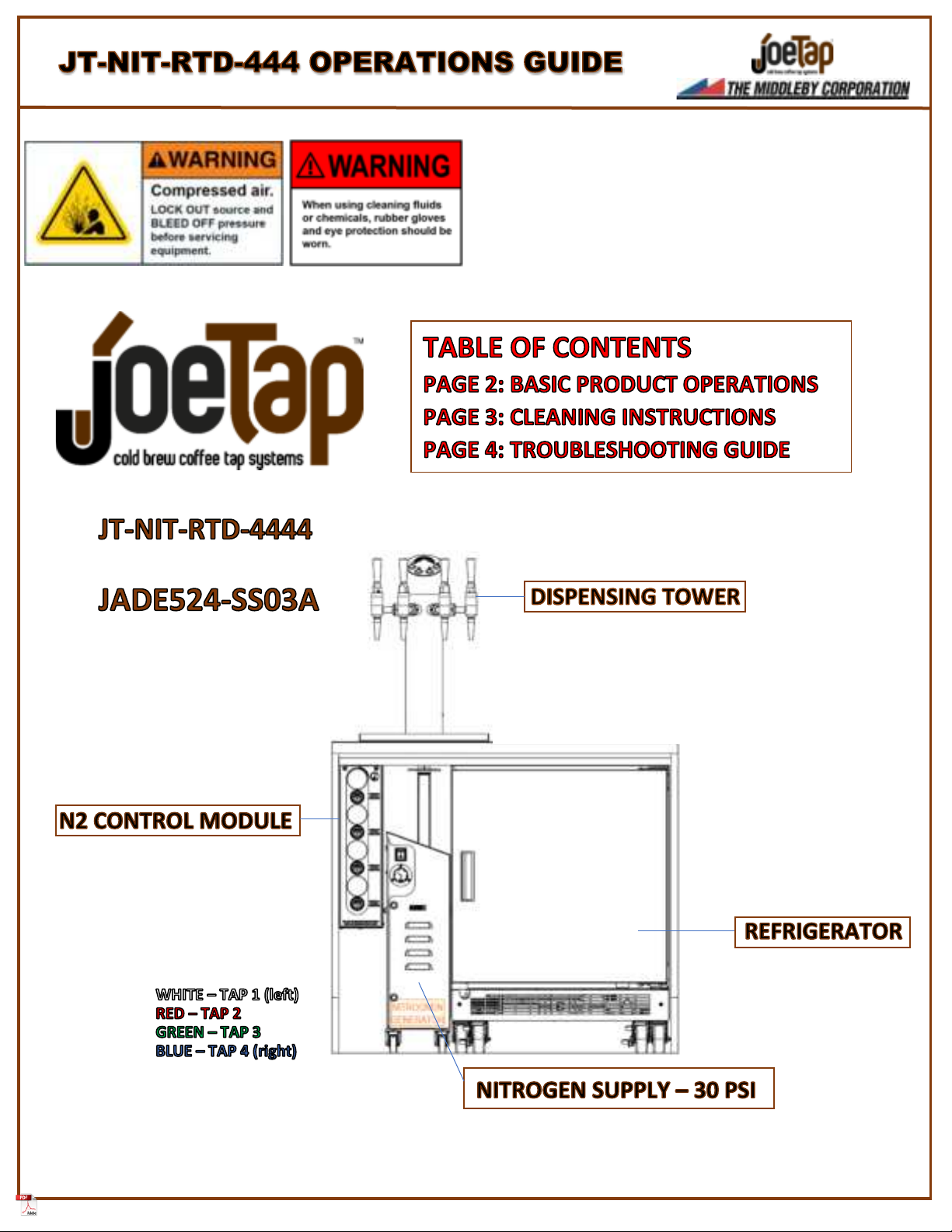

•INPUT PRESSURE 30 PSI

•Independent Nitrogen infusion

pressure adjustments and gauges

for each tap: Recommended setting

12 PSI

•Solenoid controlled N2 activation

for each tap

•Color Coded nitrogen supply lines

o

o

o

o

•Four taps/Four different beverages

•Independent Nitrogen Infusion

Control for each tap

•Illuminated switches for visual

confirmation of Nitro activation

•LED ON = Nitro Active

•Cold storage for up to 4

kegs (2.5 or 3 gallon/ea.)

•Independent temperature

and defrost controls

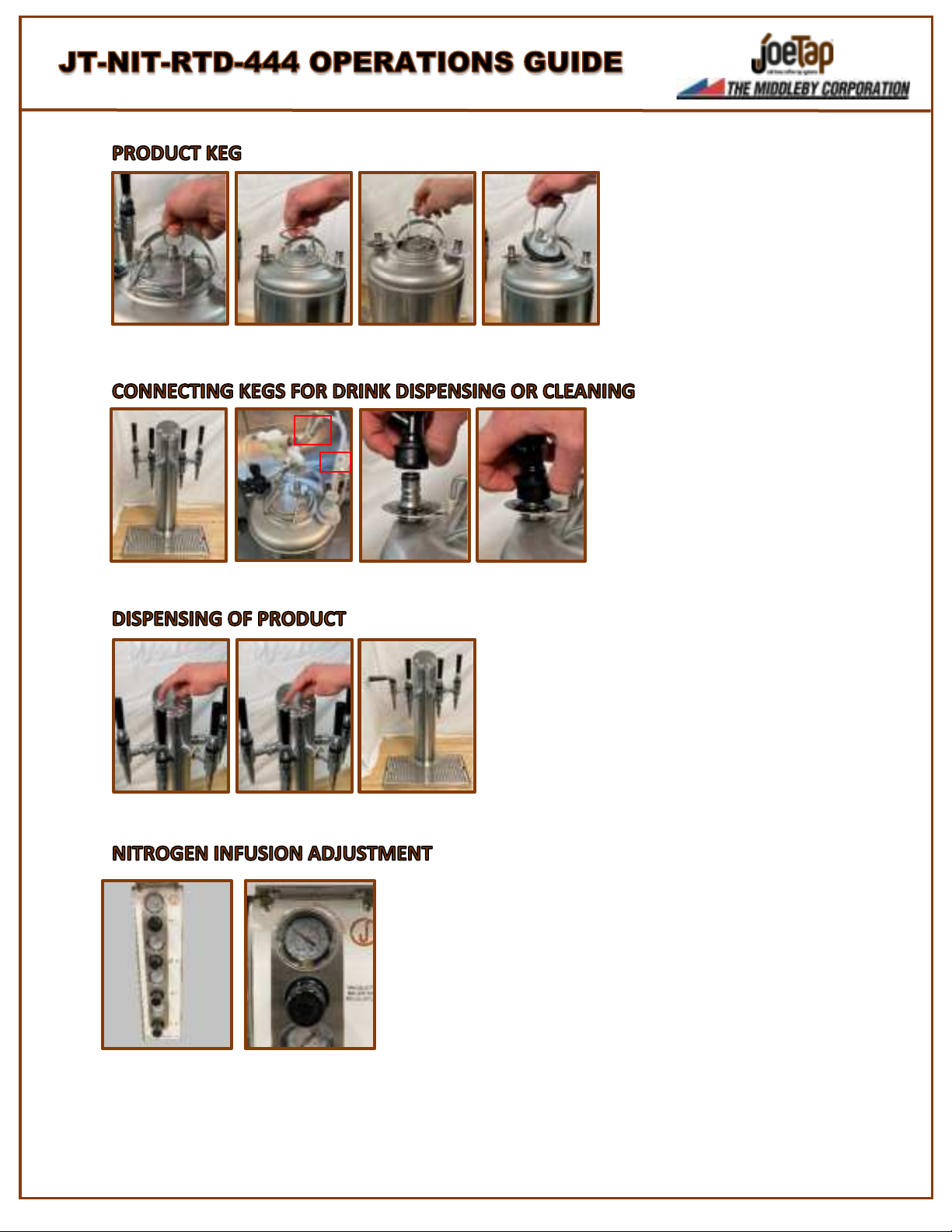

Relieve any static pressure in the product keg

by lifting the ring on the pressure relief valve.

Once drained of pressure, lift the locking

mechanism of the tank lid and press

downward on the lid to push it inside the tank.

Twist the lid sideways and tilt it slightly to

remove the lid from the tank. To re-insert and

lock the lid, reverse the steps as shown.

Using the Tap Numbers printed on the top of

the Dispensing Tower as a guide, connect the

labelled Product Supply (BLACK) and Nitrogen

Supply (GREY) lines to the correct product keg

by placing them on the keg connectors, lifting

connector sleeve upward and firmly pressing

downward until the connector locks into

place. Product lines are labelled 1-4 from left

to right to correspond with faucets on the

tower which are also 1-4 left to right.

Each of the 4 product taps can pour both nitrogen-infused and

non-infused beverages. This option is selected by pressing the

buttons at the top of the Dispensing Tower:

ILLUMINATED BUTTON = NITROGEN INFUSION

NON-ILLUMINATED BUTTON = NO NITROGEN INFUSION

Once the desired nitrogen option has been selected, pull the tap

handle to a fully horizontal position to dispense product. It is

important that the buttons are left in an illuminated position when

the system will be idle for extended periods, such as overnight.

The regulators located on the front of the Nitrogen Control Module allow for

independent control of nitrogen infusion for beverages at each tap. The gauges

will indicate the current pressure setting for each regulator. Increasing the

nitrogen pressure by turning the regulator knob CLOCKWISE will increase the

amount of nitrogen infusion in the beverage. Optimal infusion pressures will vary

depending on the type of beverage being dispensed, but generally, setting the

infusion pressures between 9 and 12 PSI will provide the desired infusion levels.

Any changes should be done in small steps as alterations of 1 PSI will have a

noticeable effect on product pours. When decreasing pressures, multiple pours

are necessary to allow the pressures to stabilize.

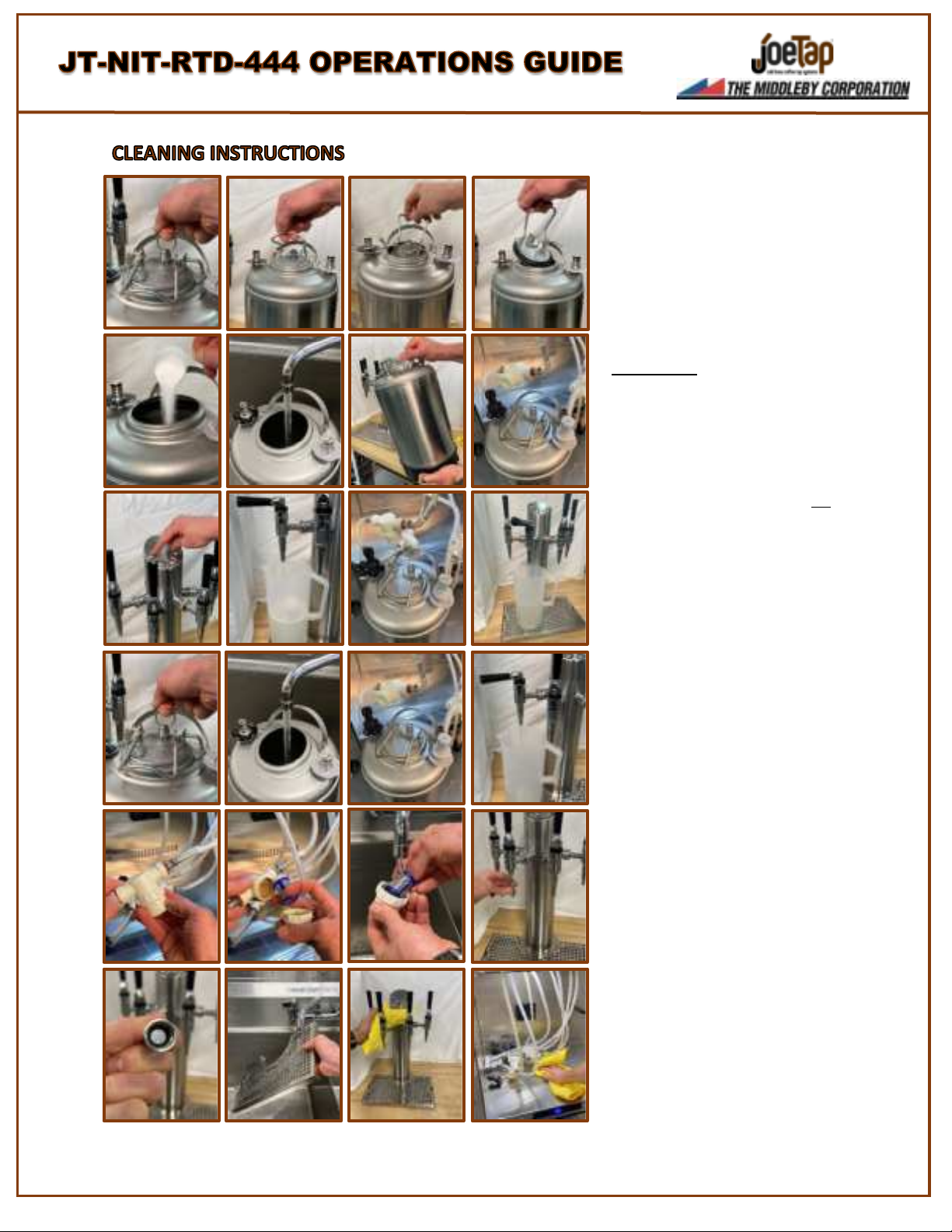

Relieve any static pressure in the product keg

by lifting the ring on the pressure relief valve.

Once drained of pressure, lift the locking

mechanism of the tank lid and press

downward on the lid to push it inside the tank.

Twist the lid sideways and tilt it slightly to

remove the lid from the tank.

STERA-SHEEN®: Mix one, 2-ounce packet of

Stera-Sheen® sanitizer powder with 2 gallons /

7-1/2 liters of 100°F / 38°C potable water in a

clean product tank. Gently swirl water in tank

to mix sanitizer. Connect ‘Product 1’ and ‘N1’

ball lock connectors to keg.

Ensure all Nitro select switches are not

illuminated. Open tap #1 until approximately

64 ounces of sanitizer has dispensed. Leaving

the ‘N1’ connector in place, switch the liquid

Ball-Lock connector to ‘Product 2’. Open tap

#2 until 64 ounces of sanitizer has been

dispensed. Repeat this process for taps #3 and

#4. Disconnect keg and relieve pressure.

Allow sanitizer to remain in the system for 5

minutes. Rinse the keg well and refill with 100°

water. Follow the same procedure as the

sanitizing process by connecting the ‘Product

1’ and ‘N1’ connectors to keg. Dispense 64

ounces of water from Tap #1 and continue the

rinsing process for Taps 2 –4. Disconnect keg

and relieve pressure.

Open each tap to relieve pressure from lines.

Disassemble each of the 4 product filters. If

they are too tight to unscrew by hand, use a

tool with a protective barrier to prevent

damage to the housing. Remove and rinse the

filter membranes and lower housings under

warm clean water. Reassemble the filter

housings. Unscrew all 4 Tap Nozzles and verify

the holes in the Diffusion Plates are clear of

debris.

If debris is present, wash with sanitizer over a

bucket to prevent losing nozzle internals.

Reinstall nozzles. Wash and sanitize the Drip

Tray. Using a towel moistened with sanitizer,

wipe down the tower assembly and

refrigerator.

CLEANING PROCESS COMPLETE

NO PRODUCT POUR

ALL FAUCETS

NO NITROGEN PRESSURE

VERIFY THAT THE NITROGEN GENERATOR IS PLUGGED

IN AND THE POWER SWITCH IS IN THE ‘ON’ POSITION.

IF A GAS CYLINDER IS BEING USED, VERIFY SUFFICIENT

PRESSURE WITHIN THE TANK BY CHECKING THE

PRESSURE GAUGE ON THE OUTPUT REGULATOR.

NO PRODUCT POUR

SINGLE FAUCET

NO PRODUCT IN KEG

REMOVE BOTH THE GRAY AND BLACK CONNECTORS

FROM KEG AND RELEASE THE PRESSURE BY LIFTING

THE RING ATOP THE PRESSURE RELIEF VALVE.

REMOVE LID AND VERIFY AMPLE PRODUCT IN KEG.

BAD CONNECTION AT PRODUCT KEG

REMOVE BOTH THE GREY AND BLACK BALL-LOCK

CONNECTORS FROM THE KEG AND RE-INSERT THEM

FIRMLY.

PRODUCT FILTER IS CLOGGED

REMOVE BLACK BALL-LOCK CONNECTOR FROM

AFFECTED PRODUCT KEG AND BRIEFLY OPEN THE

AFFECTED TAP TO REMOVE PRESSURE FROM THE

LINE. UNSCREW BOTTOM OF FILTER HOUSING, THEN

REMOVE FILTER ELEMENT INSIDE. CLEAN ELEMENT

WITH APPROVED SANITIZER AND RE-INSTALL.

RECONNECT KEG AND VERIFY OPERATIONS.

NOZZLE AT TAP IS CLOGGED

REMOVE NOZZLE FROM DISPENSING FAUCET AND

CHECK FOR BLOCKAGE. IF BLOCKAGE IS PRESENT,

REMOVE NOZZLE INTERNALS AND CLEAN WITH

APPROVED SANITIZER.

NITRO POUR ONLY

ALL FAUCETS

POOR CONNECTION TO POWER SUPPLY

VERIFY THAT THE LOW-VOLTAGE POWER SUPPLY

CONNECTOR IS PROPERLY INSERTED INTO THE BACK

OF THE NITROGEN CONTROL MODULE AT THE LOWER

SECTION OF THE REAR PANEL.

PRIMARY NITROGEN PRESSURE TOO HIGH

VERIFY PRESSURE OUTPUT OF NITROGEN SOURCE IS

SET TO 30PSI. ADJUST OUTPUT REGULATOR AS

NEEDED.

ALL PRODUCT HAS BEEN EXPOSED TO NITROGEN

PRESSURE FOR MORE THAN 48 HOURS

DISCARD PRODUCT AND CONNECT A KEG OF FRESH

PRODUCT TO AFFECTED TAPS.

NITRO POUR ONLY

SINGLE FAUCET

PARTIALLY CLOGGED NOZZLE/MISSING RESTRICTOR DISK

REMOVE NOZZLE FROM DISPENSING FAUCET AND

CHECK FOR BLOCKAGE OR MISSING RESTRICTOR DISK.

IF BLOCKAGE IS PRESENT, REMOVE NOZZLE

INTERNALS AND CLEAN WITH APPROVED SANITIZER.

PRODUCT HAS BEEN EXPOSED TO NITROGEN PRESSURE

FOR MORE THAN 48 HOURS

DISCARD PRODUCT AND CONNECT A KEG OF FRESH

PRODUCT TO AFFECTED TAPS.

NON-NITRO POUR

ONLY –SINGLE

FAUCET

MANUAL NITROGEN SHUT-OFF VALVE IS CLOSED

VERIFY THAT THE MANUAL NITROGEN SHUT-OFF

VALVES LOCATED AT THE BASE OF THE TOWER,

UNDER THE COUNTERTOP, ARE IN THE OPEN

POSITION.

NITRO CARRYOVER

WHEN SWITCHING

FROM NITRO POUR

TO NON-NITRO POUR

INFUSION REGULATOR SET TOO HIGH

AT THE FRONT OF THE NITROGEN CONTROL MODULE,

PULL THE KNOB OF THE AFFECTED REGULATOR TO

UNLOCK IT. SLIGHTLY ROTATE COUNTER-CLOCKWISE

AND CONDUCT A TEST POUR. CONTINUE

ADJUSTMENT AND TEST AS NEEDED. (9-12PSI)

PRIMARY NITROGEN PRESSURE TOO HIGH

VERIFY PRESSURE OUTPUT OF NITROGEN SOURCE IS

SET TO 30PSI. ADJUST OUTPUT REGULATOR AS

NEEDED.

PRODUCT HAS BEEN EXPOSED TO NITROGEN PRESSURE

FOR MORE THAN 48 HOURS

DISCARD PRODUCT AND CONNECT A KEG OF FRESH

PRODUCT TO AFFECTED TAPS.

This manual suits for next models

1

Other JoeTap Accessories manuals