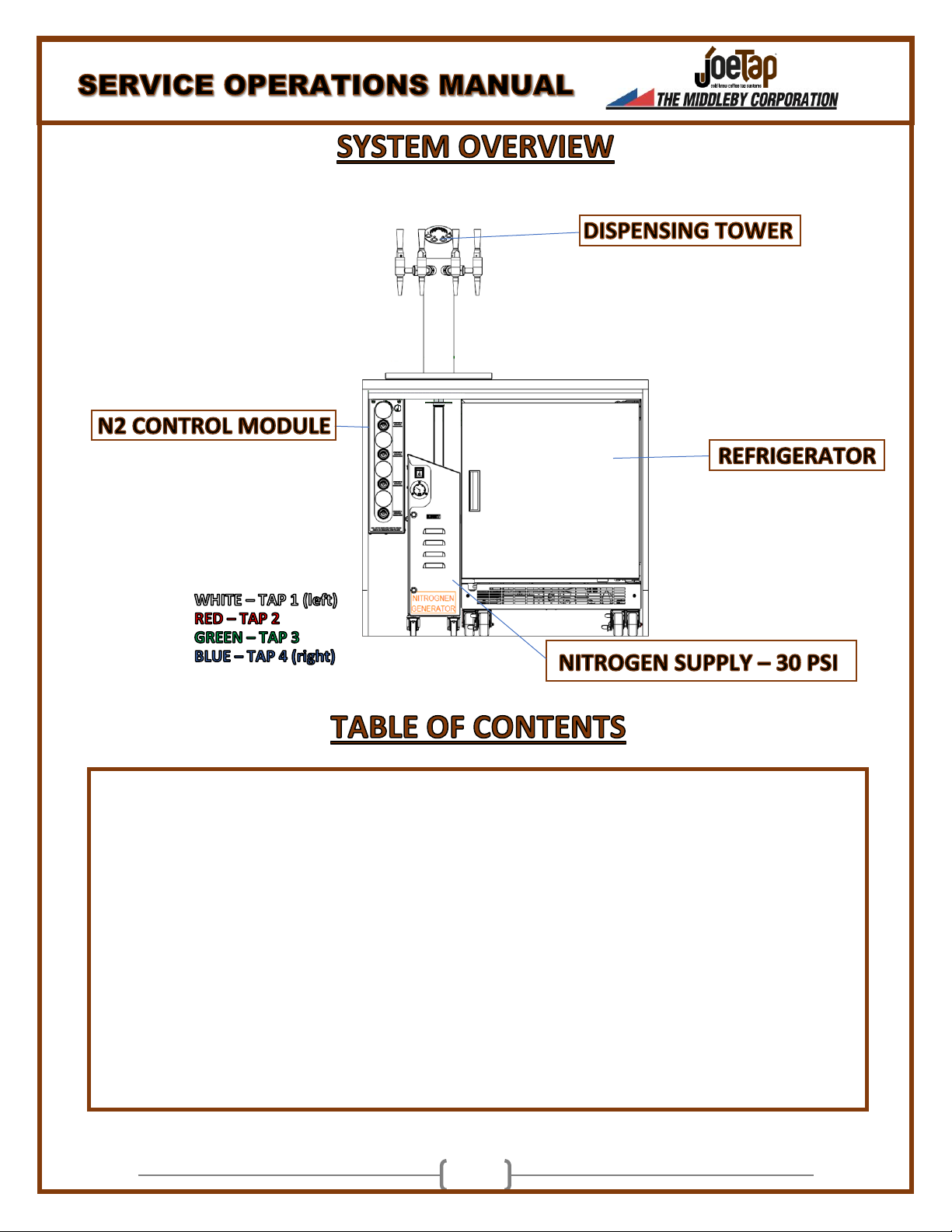

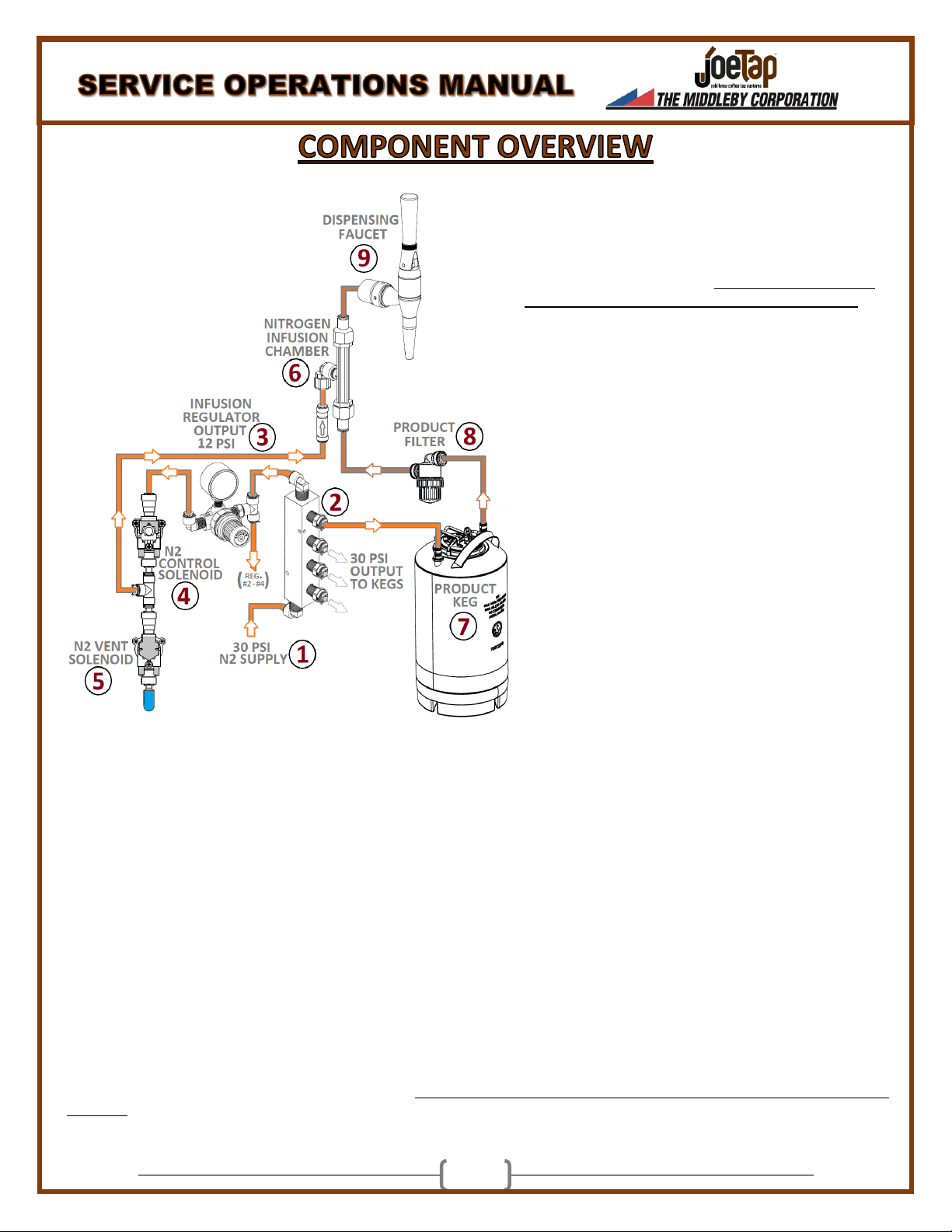

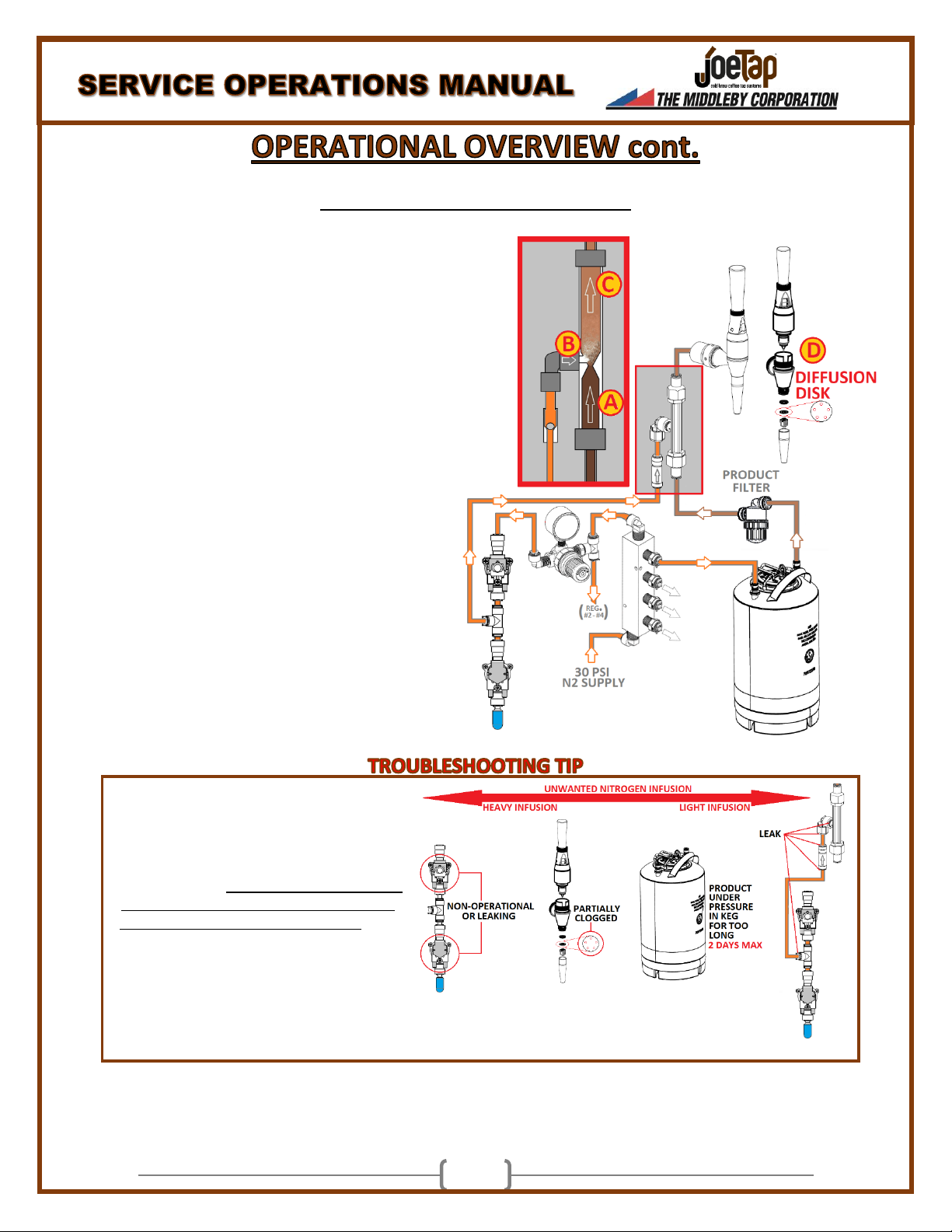

1. 30 PSI N2 SUPPLY INPUT

LOCATION: REAR PANEL OF N2 CONTROL MODULE.

N2 supplied via a Nitrogen generator or compressed gas cylinder.

Adjustments to this pressure can be made via a regulator at the

output of either nitrogen source. Supply pressure dictates the

amount of pressure displacing liquid from the product keg.

Factory recommended setting: 30 PSI (50PSI MAX)

2. NITROGEN DISTRIBUTION BLOCK

LOCATION: INSIDE N2 CONTROL MODULE

Distributes incoming N2 Pressure to 4 separate kegs in the

refrigerator. These pressures are not independently adjustable.

3. INFUSION REGULATORS (X4)

LOCATION: FRONT OF N2 CONTROL MODULE

Regulates N2 Pressure to each tap for proper infusion with liquid

product within the N2 Infusion Chamber (6). Easily adjusted at

the front of N2 Control Module. Increasing this pressure will add

more froth to final product.

Factory recommended setting: 12 PSI.

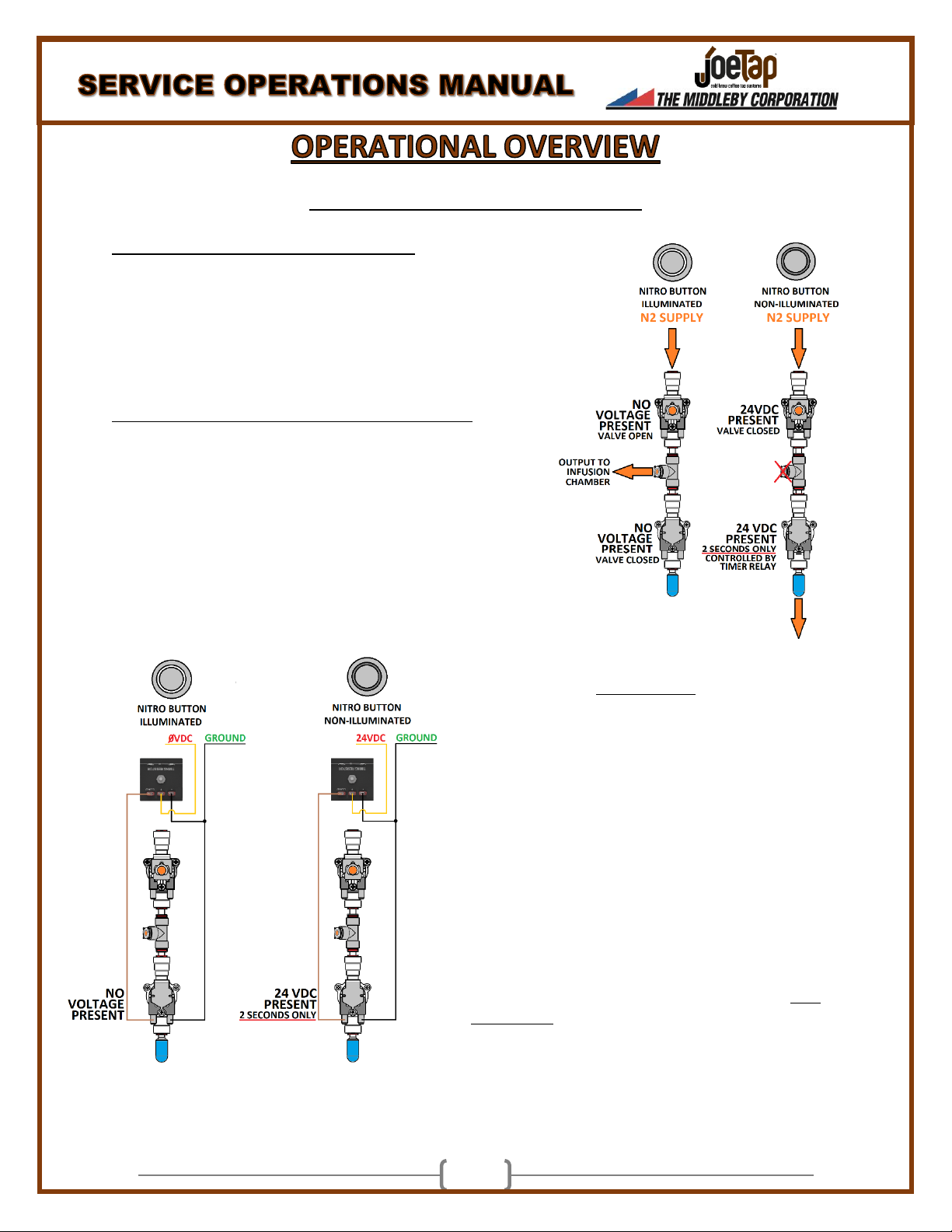

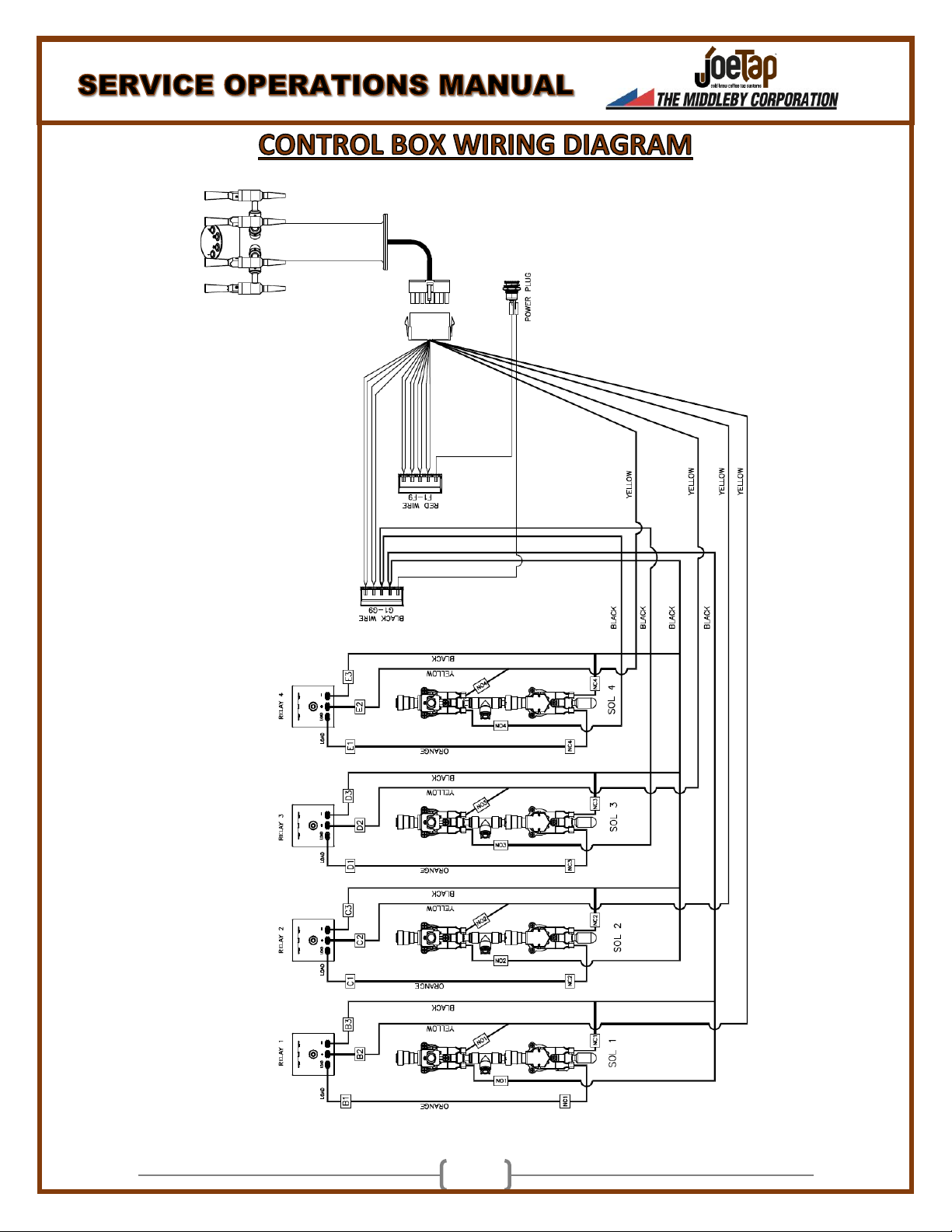

4. N2 CONTROL SOLENOID (X4 -Normally

Open/24VDC/88-90Ω)

LOCATION: INSIDE N2 CONTROL MODULE.

Activated by the Nitrogen Select buttons at the top of the

Dispensing Tower, the N2 Control Solenoids determine the

presence of N2 pressure at the Infusion Chamber. These valves

are NORMALLY OPEN. An illuminated N2 Select Button DOES

NOT apply 24VDC to the valve, allowing a nitrogen infused

beverage to be dispensed.

5. N2 VENT SOLENOID (X4 -Normally Closed/24VDC/88-90Ω)

LOCATION: INSIDE N2 CONTROL MODULE.

When N2 supply pressure to the Infusion Chamber is stopped by the N2 Control Solenoid, any static N2 pressure in the supply line is vented

through the N2 Vent Solenoid for 2 seconds. This is controlled via Timer Relays inside the N2 Control Module.

6. NITROGEN INFUSION CHAMBER (X4)

LOCATION: INSIDE DISPENSING TOWER

Nitrogen pressure controlled by the N2 Control Solenoid is blended with liquid product from the kegs to produce a nitrogen infused beverage.

7. PRODUCT KEG (UP TO 4)

LOCATION: INSIDE REFRIGERATOR

Rated at 2.5 or 3 gallons, these product kegs store beverage products prepared by the customer. Liquid is forced from the kegs by incoming

Nitrogen pressure at 30 PSI. *NOTE* Storing product kegs under Nitrogen pressure for more than 48 hours will saturate the product with

Nitrogen gas and cause frothy beverages to be dispensed at all times.

8. PRODUCT FILTER (X4)

LOCATION: INSIDE REFRIGERATOR

A removable and cleanable particulate filter that prevents clogging of smaller orifices within the dispensing tower

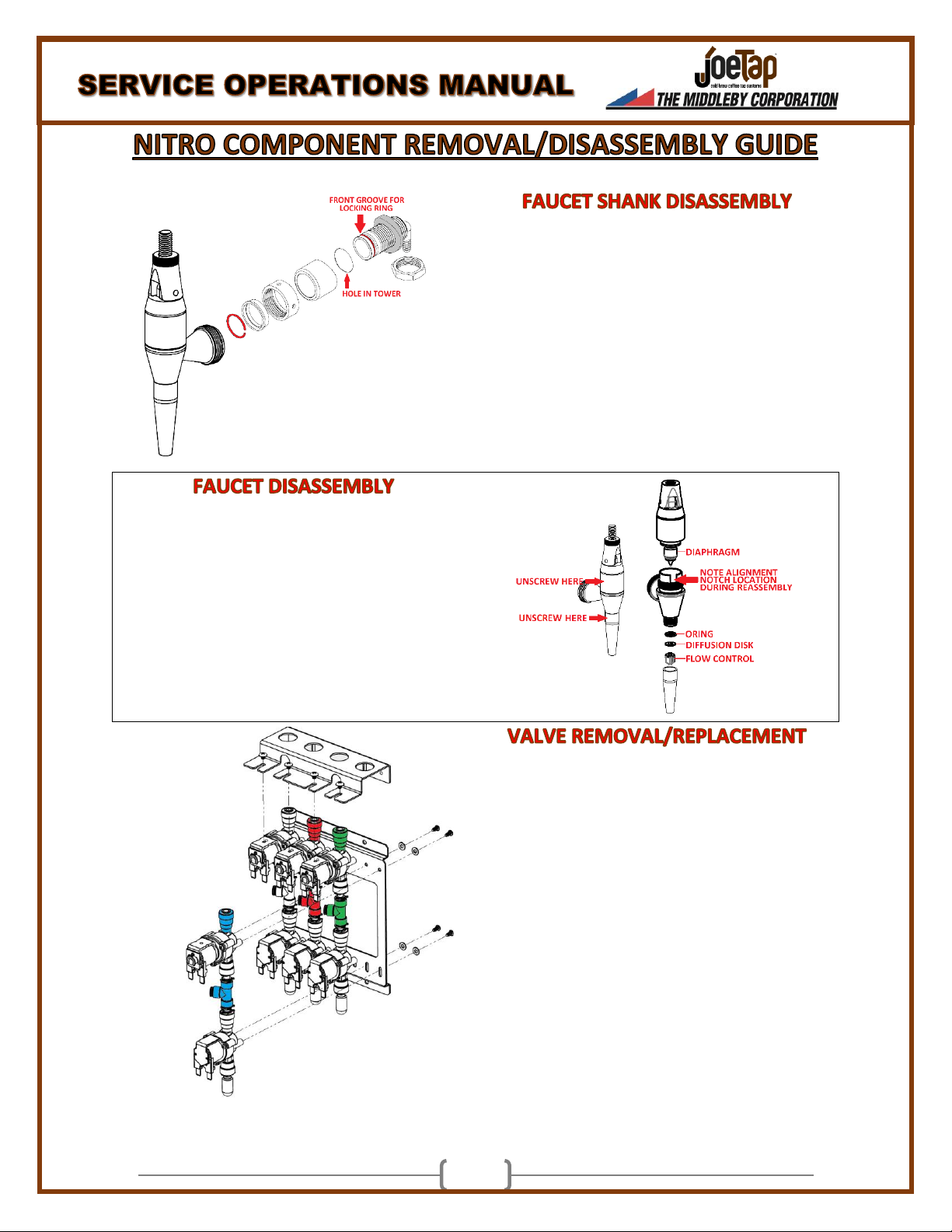

9. DISPENSING FAUCET (X4)

LOCATION: TOP OF DISPENSING TOWER

A manually operated lever utilized for dispensing of product. It is important that the lever is pulled to a completely horizontal position for proper

dispensing. The faucet is serviceable with available internal components.