General Specification

The ranges of Metastream couplings covered by this manual, are designed to transmit torque

between the rotating shafts of a driving and driven machine, whilst accomodating the inevitable

lateral, angular and axial misalignment, which will exist between two coupled machines.

The usual extentof supply comprises:

•a hub for the DRIVING machine (motor) shaft

•a hub for the DRIVEN machine shaft

•a factory assembled transmission unit, comprising two packs of flexible metallic discs,each

bolted to a “guard ring” and to a common spacer (distance piece), which separates the two disc

packs, The overall length of the transmission unit issized to suitthe shaft end separation of the

coupled machines

•a set of fasteners to assemble the transmission unitto the two hub flanges.

IMPORTANT

These instructions should be read in conjunction with any application specific general arrangement

drawing which maybe supplied with the coupling.

Selection verification

Although a coupling may be correctly specified at the time of order placement, the duty conditions

can sometimes change prior to the coupling being put into service. Information is available from

John Crane to advise on the selection and limitations of their power transmission products, but the

USER is ultimately responsible for verifying the suitability of the selection for the actual service

conditions.

The coupling and its manner ofuse must conform to any legal or licensing requirements, and, where

appropriate, meetlocal health and safety requirements.

IMPORTANT: If the conditions of operations are changed without approval from John Crane, then

we would decline responsibility for anyconsequentdamage and the USER would assume all risks.

Documentation supplied with the coupling should be retained for future reference.

Unpacking and Storage

The coupling should be unpacked and examined for any signs of transit damage. Particular attention

should be paid to hub bores and spigot/recess local diameters.

If the coupling is not to be used immediately, it should be re-packed and stored in a dry place away from

directheat.

Documentation supplied with the coupling should be retained for future reference.

Installation

Prior to installing the coupling ensure that the machinery is made safe

•Remove the coupling from its packaging and carefully inspect for signs of damage. Particular attention

should be paid to the hub bores and the spigot/recess location features, which should be free from

burrs and other damage.

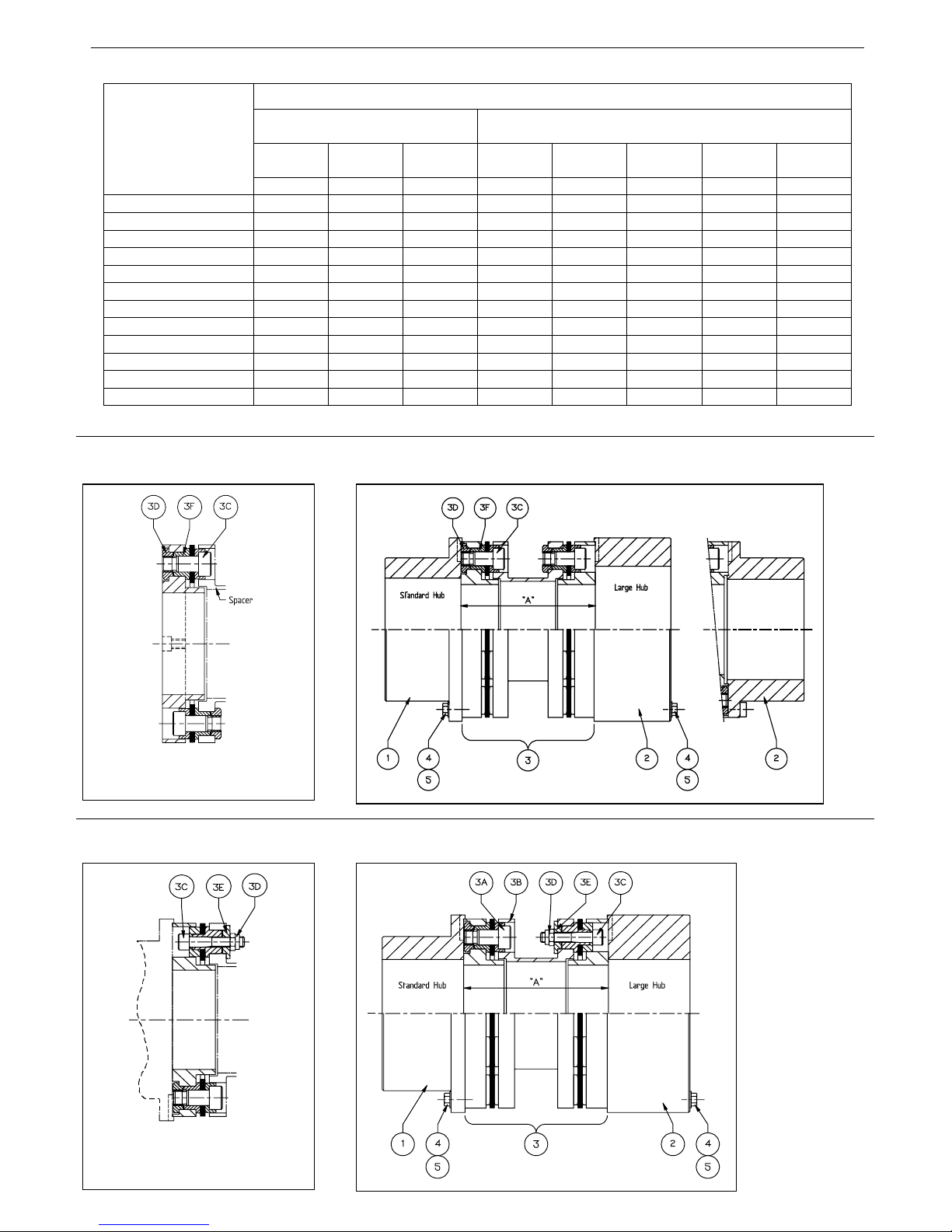

•Fit the Driver (1) and Driven (2) hubs to the corresponding machine shafts. Normally, John Crane

supply parallel bored and keywayed hubs, individually machined to give a light interference fit with the

associated shaft. If it is necessary to apply some heating to the hub to assist fitting, then a warm oil

bath will usually be adequate.

Hubs must be adequately supported during installation to avoid accidental damage should

they slip.

It is usual to install the hub such that the hub face and shaft end are flush, but consultthe arrangement

drawing, or other particular instructions,to check the configuration for individual designs.

Align the centre lines of the driving and driven machine shafts as follows:

•With one machine firmly bolted down, set the distance between shaft ends (DBSE) according to

drawing or catalogue dimension ‘A’

IMPORTANT: DBSE is usually measured between the inner face of the hubs and should not be

taken as the length of the transmission unit at its maximum diameter

•Align the shaft centre lines both horizontallyand vertically byaligning the hub flanges. The John Crane

coupling alignment kit and reverse peripheryprocedure allows rapid and accurate alignment of shafts.

IMPORTANT: The misalignment tolerances quoted in literature and on drawings allow for dynamic

conditions and variations. For the best service from the coupling, John Crane recommend that

installed misalignment is no more than10% ofthe maximum allowable misalignment, allowance being

made for any anticipated movements which will occur during operation (eg. thermal movements on

hut pumps).

•Check spigot and recess locations on the hubs and transmission unit for burrs or other signs of damage

and then fit the transmission unit(3) between the hubs.

THE TRANSMISSION UNIT MUST BE ADEQUATELY SUPPORTED DURING INSTALLATION

TO AVOID ACCIDENTAL DAMAGE SHOULD IT SLIP.

It may be necessary to compress the transmission unit whilst sliding it between the hubs, and facilities are

provided to make it easier:

1. on smaller units,lever slots are provided in the hub flanges

2. on larger units, including the TLK, the spacer flanges are drilled so

that the hub bolts (4) may be used to compress the transmission unit

sufficiently to clear the spigot location (see sketch).

Maximum compression ofthe gap ‘X’ should notexceed 0.8 times the

coupling maximum axial misalignement value, unless indicated

otherwise on the general arrangement drawing.

IMPORTANT: Always remove the compression bolts as soon as the transmission unit is in position

and before fully tightening the hub bolts.

Fit the hub bolts (4) (and locking washers (5) if supplied) and tighten these evenly to locate the transmission

unit, ensuring that the spigots enter their recess squarely. Boltsshould be tightened in a “diametrically

opposite” sequence to the valuesquoted in Table 1.If a general arrangement drawing issupplied with the

coupling, then torque values quoted on that drawing take precedence.

•Rotate the machinery two or three timesslowly to ensure it moves freely.

The coupling is now ready for continuous and trouble free service.

John Crane Italia SpA

Via Giotto 3

20053 Muggiò (MI)

Tel. 039-2714.1

Fax 039-2714.300

Operation

BEFORE STARTING THE MACHINERY, ENSURE THAT ALL NECESSARY SAFETY

PROCEDURES ARE BEING OBSERVED

When operated within the duty conditions for which they were designed, John Crane Metastream

flexible disc couplings will give long and trouble free service. Routine examination should include

a periodic check on the tightness of fasteners and visual inspection of transmission components

for signs offatigue or wear.

Ifthe coupled machinery isdisturbed atany time, then shaft alignment should be re-checked as a

matter of routine. Alignment checking is also recommended if a deterioration of installation

alignment during service is suspected.

Inspection and Maintenance

MAINTENANCE WORK MUST ONLY BE CARRIED OUT BY SUITABLY QUALIFIED

PERSONNEL WHEN THE EQUIPMENT IS STATIONARY AND HAS BEEN MADE SAFE

John Crane Metastream flexible power transmission couplings are designed to give long and

trouble free service if operated within the conditions for which they were specified. Failures are

rare and can generally be attributed to:-

•excessive misalignment

•severe torsional overload

In all cases of coupling failure, the cause should be identified and corrected before replacing the

coupling.

The usual mode of failure of flexible disc couplings is rupture of the flexing membranes. In such

circumstances, it is possible to repair the coupling byfitting a replacement disc pack assembly.

ATTENTION: When repairing John Crane Metastream flexible disc couplings, only John

Crane approved parts should be used.

•To replace the transmission unit (3), first remove the hub bolts (4) and then withdraw the

transmission unitusing the lever slots in the hubs or compression bolt feature in the spacer as

appropriate.

TRANSMISSION UNIT MUST BE ADEQUATELY SUPPORTED DURING REMOVAL

TO AVOID ACCIDENTAL DAMAGE SHOULD IT SLIP

•Identify the bolts which connect the disc packs to the spacer piece. Slacken and remove

these drive bolts (3C) and nuts (3D) and carefully dismantle the disc pack assemblies from

the spacer piece. Do not attempt to dismantle the disc pack assemblies any further;

replacementdisc packs are always supplied complete with a new guard ring.

•Subsequent refurbishment is dependent on the type of coupling involved and the precise

configuration of the replacement membrane pack. It is recommended that BOTH membrane

packs be replaced,as failure of one inevitably results in some damage to the other.

TSP (TSA) REPLACEMENT PACK

•Complete the removal ofthe old disc packassemblies by pressing the washers(3E) out of the

holes in each spacer flange.

•Identify the fasteners which attach the disc packs to the spacer. Disassemble the loosely

assembled nuts (3D) and separate the bolts (3C)and washers (3E).

•Fit new washers (3E) into the spacer.

•Carefully press the protruding sleeves in each disc pack into the holes in the spacer flange,

taking care notto over-strain the flexible discs. Insertthe drive bolts (3C) from the guard ring

side and secure using the locknuts (3D). Tighten the locknuts evenly to the correct SPACER

BOLT tightening torque value given in Table 1.

•Complete the refurbishment of the transmission unit by replacing the second disc pack

assembly.