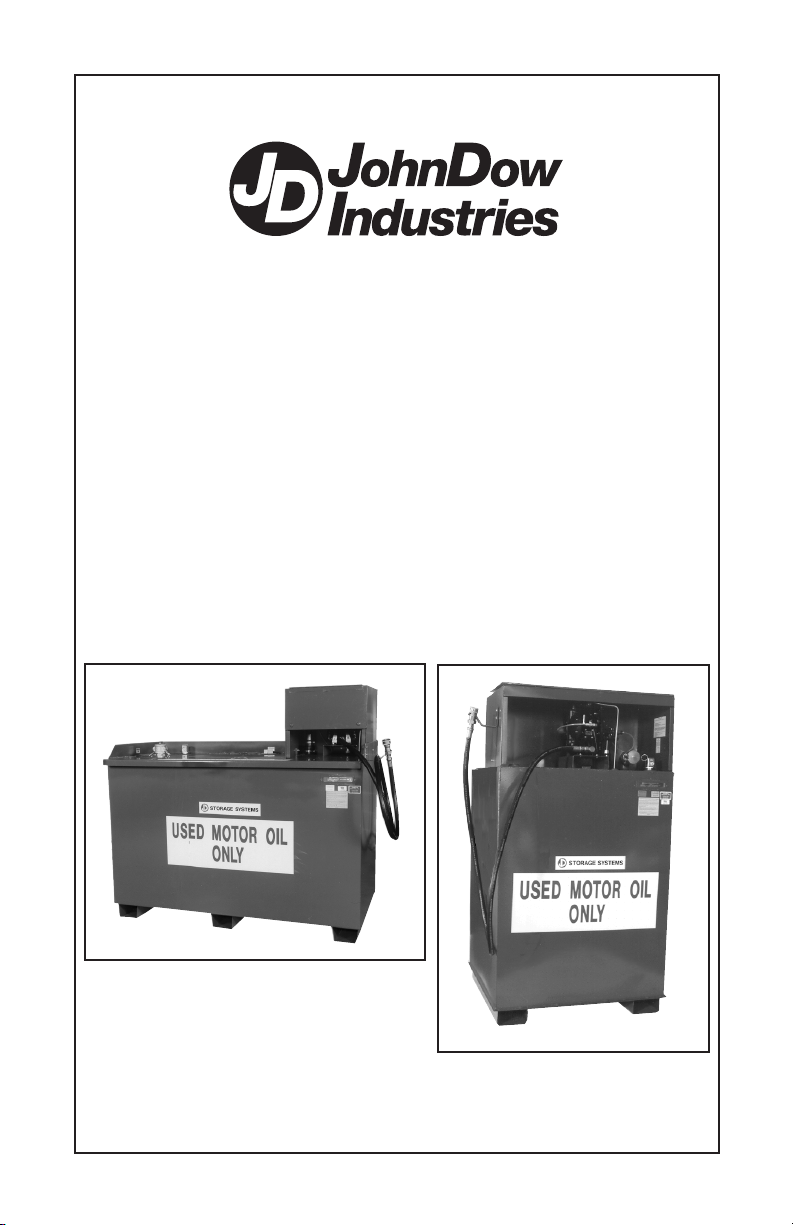

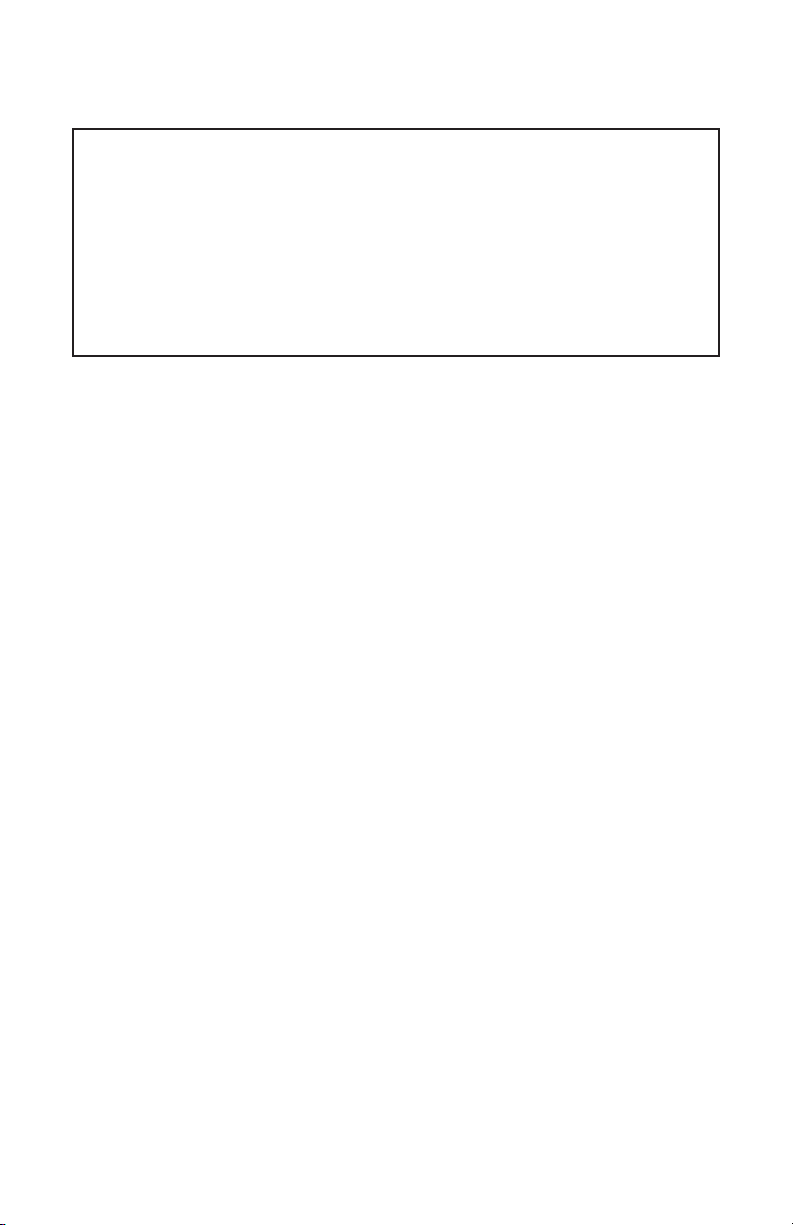

Assembly Instructions Operating Instructions

Please read the following before pro eeding with installation

and operation of the JohnDow Used Oil Storage System.

Installation:

1. Position the tank in a lo ation that is within 2” of level.

2. Atta h the 10’ x 3/4” intake hose to the pump.

3. Install the liquid level gauge in the 2” oupling at the left

read of the tank a ording to the instru tions provided

with the gauge.

4. If required by lo al regulations, install ne essary venting

through the 4” oupling lo ated at the enter of the tank.

5. Install the hose hanger by bolting it on the outside of the

tank.

6. Atta h air supply to the onne tion on the rear of the

se urity abinet.

7. Install qui k dis onne t adapter to waste oil drain.

Operation:

1. Position the full waste oil drain next to the system and

onne t the intake hose to the drain.

2. Open the valve on the waste oil drain assembly.

3. Turn on the air supply to start the pump and transfer of

used oil

4. When the oil drain is empty - dis onne t the hose and

then turn off the air supply.

Automatic Overfill Protection

The JohnDow Used Oil Storage System is equipped with an automati

air shut-off valve that stops the air supply to the pump to prevent over-

filling and overflowing the tank. The air valve will engage when the tank

is at approximately 85% of apa ity.

Do not attempt to override the shut-off valve as this may ause damage

to the valve assembly and result in overflowing the tank. Call your used

oil hauler immediately.

Double-Wall, 110% Secondary Containment

The double-wall tank design provides prote tion against oil leakage in

the unlikely event the inner tank should fail. The outer tank will ontain

over 110% of the volume of the inner tank.

Two oupling on the extreme left end of the tank allows for inspe tion of

the outer tank ontainment hamber. Use aution to avoid pouring any

oil into the outer tank hamber.

Security Cover

The se urity over prote ts the pump and shut-off valve from damage.

If it is ne essary to remove this over, the air supply must be dis on-

ne ted from the ba k inside of the over first. The qui k dis onne t air

fittings allow the air hose to be removed by simply depressing the grey

ring around the plasti hose and pulling the hose out. The re onne t,

push the hose into the fitting unit, it is se ure.

.L. Listed 1” Diaphragm Pump

The air diaphragm pump is designed to run effi iently at 60 psi. The air

regulator is pre-set at the fa tory and should not need adjustment.

If the pump fails to run:

• Make sure the air supply is properly hooked up.

• Make sure the tank is not full and automati shut-off has ut the air

supply.

If the pump runs but is not pumping oil:

• Dis onne t the intake hose from the pump and he k for su tion at

the hose onne tion point. If there is su tion at the pump, then he k

the qui k dis onne t oupler on the other end of the hose for debris

that ould be blo king the flow.

• If there is no su tion at the pump, all our Servi e Department at

1-800-433-0708 for help.

CA TION:

Before attempting to transfer oil, always check the tank level

to determine if sufficient capacity is available. This will pre-

vent possible overfilling of the tank. Call your authorized

used oil hauler to evacuate the tank.