900589-UIM-A-1012

4Johnson Controls Unitary Products

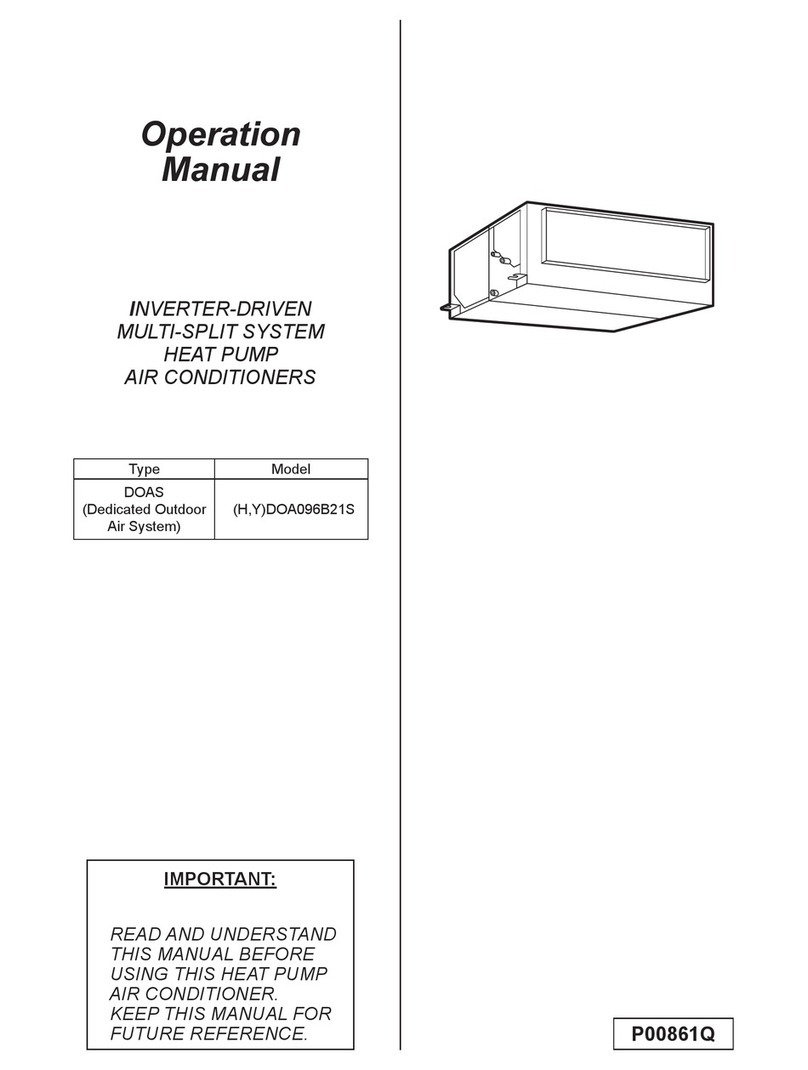

CRITICAL COIL PROJECTION

The coil assembly must be located in the duct such that a minimum dis-

tance is maintained between the top of the coil and the top of the duct.

Refer to Table 4.

SECTION IV: DUCT CONNECTIONS

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an instal-

lation that the duct system be properly designed and installed.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space.

Where return air duct is short, or where sound may to be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of duct work is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorp-

tion of moisture from the surrounding air into the insulation. The supply

air duct should be properly sized by use of a transition to match unit

opening. All ducts should be suspended using flexible hangers and

never fastened directly to the structure. Duct work should be fabricated

and installed in accordance with local and/or national codes. This

includes the standards of the National Fire Protection Association for

Installation of Air-Conditioning and Ventilating Systems, NFPA No. 90B.

SECTION V: CONDENSATE DRAIN

CONNECTIONS

All drain lines should be pitched away from unit drain pan and should be

no smaller than the coil drain connection.

Route the drain line so that it doesn’t interfere with accessibility to the

coil, furnace, air handling system or filter and will not be exposed to

freezing temperatures.

Instruct the owner that the evaporator coil drain pan should be

inspected and cleaned regularly to prevent odors and assure proper

drainage.

Coils should be installed level or pitched slightly toward the drain end.

Suggested pitch should not exceed 1/4-inch per foot of coil.

If the coil is provided with a secondary drain it should be piped to a loca-

tion that will give the occupant a visual warning that the primary drain is

clogged. If the secondary drain is not used it must be capped.

DO NOT use TeflonTM tape, “pipe dope”, or other sealants. The use of a

sealant may cause damage and premature failure of the drain pan.

SECTION VI: REFRIGERANT LINE

CONNECTION

Connect lines as follows:

1. Suction and liquid line connections are made outside the duct.

2. Wrap a water soaked rag around the coil connection tubes inside

the duct to avoid damaging the TXV bulb.

3. Purge refrigerant lines with dry nitrogen.

4. Braze the suction and liquid lines.

5. Attach the duct access panel to the duct.

Refer to Outdoor unit Installation Manual for evacuation, leak check and

charging instructions.

Lines should be sound isolated by using appropriate hangers or strap-

ping.

All evaporator coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or

equivalent. DO NOT use soft solder.

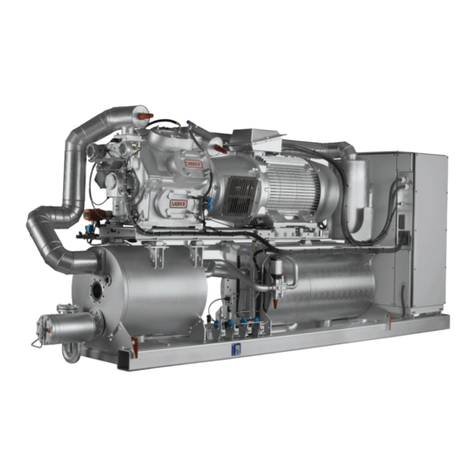

FIGURE 5: Upflow Coil Installation

TABLE 3:

Coil Projection Dimensions - UC Coils

COIL SIZE DIMENSION “C” INCH

UC18 3-1/2

UC24 4-1/2

UC30 4-1/2

UC36 5-1/2

UC48 6-1/2

UC60 9

Dimension “C” should be at least 2/3 of dimension “D”. See Figure 5.

Equipment should never be operated without filters.

FIELD

FABRICATED

COIL ACCESS

FIELD

FABRICATED

SUPPORT

BRACKETS (x2)

“C” (MIN.)

“D”

FIELD

FABRICATED

DUCTWORK

3” (MIN.)

UPFLOW

FURNACE

AIR

FLOW

Avoid Double Trapping.

Threaded drain connections should be hand tightened, plus no more

than 1 turn.

Coil is under inert gas pressure. Relieve pressure from coil by

depressing schrader core.

Dry nitrogen should always be supplied through the tubing while it is

being brazed, because the temperature required is high enough to

cause oxidation of the copper unless an inert atmosphere is provided.

The flow of dry nitrogen should continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only

low pressure dry nitrogen is introduced into the tubing. Only a small

flow is necessary to displace air and prevent oxidation.

Route the refrigerant lines to the coil in a manner that will not

obstruct service access to the coil, air handling system, furnace flue

or filter.