Johnson Controls JMW Series Owner's manual

Other Johnson Controls Heat Pump manuals

Johnson Controls

Johnson Controls VBR09 Series User manual

Johnson Controls

Johnson Controls PHE4 Series User manual

Johnson Controls

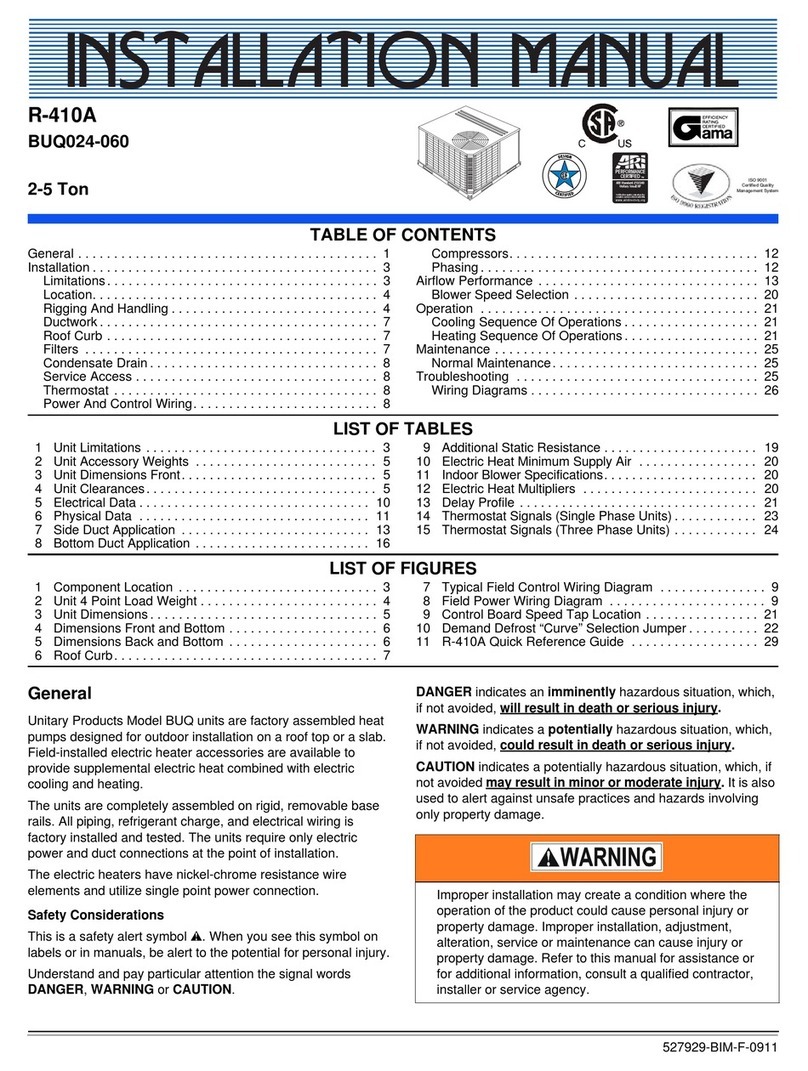

Johnson Controls Duct R-410A Quick start guide

Johnson Controls

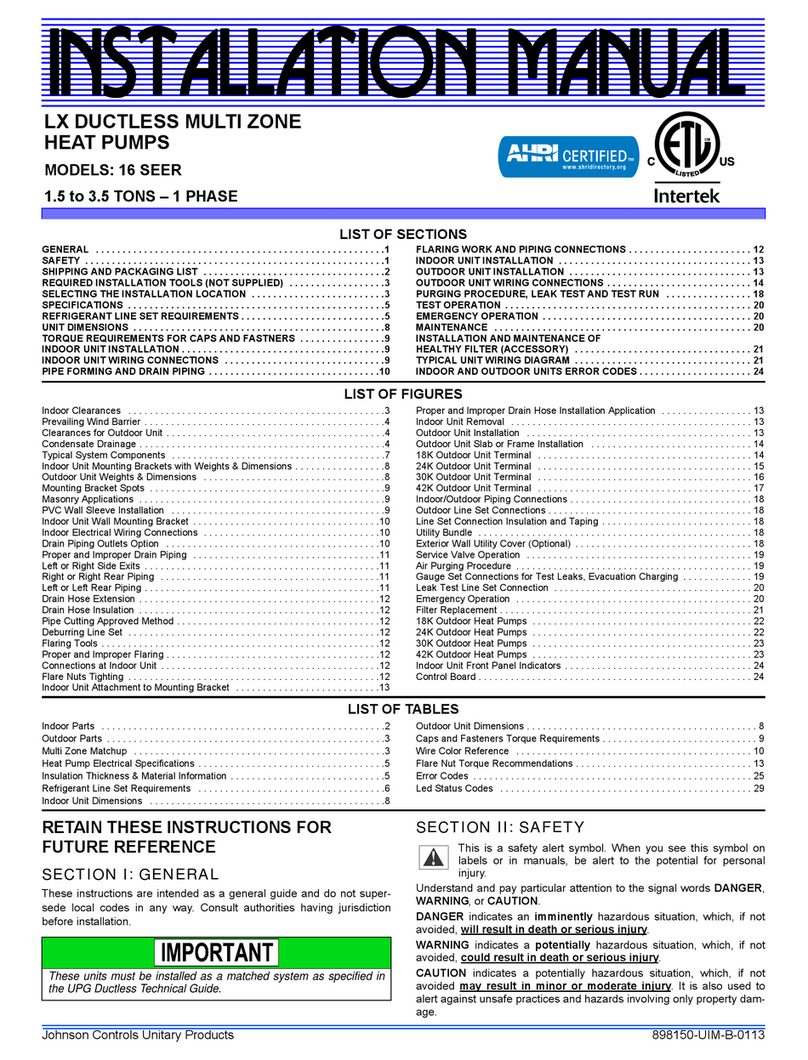

Johnson Controls LX Series Quick start guide

Johnson Controls

Johnson Controls YORK BCHO-74G Manual

Johnson Controls

Johnson Controls XAF Series User manual

Johnson Controls

Johnson Controls 15 SEER - YZE / HC5B / HL5B SERIES User manual

Johnson Controls

Johnson Controls RC Series User manual

Johnson Controls

Johnson Controls YORK EUKC-09 AA User manual

Johnson Controls

Johnson Controls Duct R-410A User manual

Johnson Controls

Johnson Controls 13 SEER - THGD User manual

Johnson Controls

Johnson Controls JE-Series User manual

Johnson Controls

Johnson Controls UC User manual

Johnson Controls

Johnson Controls Frick IDC2 User manual

Johnson Controls

Johnson Controls HMH7 Series User manual

Johnson Controls

Johnson Controls RJ H Series Owner's manual

Johnson Controls

Johnson Controls PREMIUM EFFICIENCY VPCS Series Installation and operating instructions

Johnson Controls

Johnson Controls VB09 Installation and operating instructions

Johnson Controls

Johnson Controls CHJD Series User manual

Johnson Controls

Johnson Controls DHPM09NWM42Q1 User manual

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

Carrier

Carrier WSHP Open v3 Integration guide

TGM

TGM CTV14CN018A Technical manual

Carrier

Carrier 38MGQ Series installation instructions

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Carrier

Carrier 48EZN installation instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet