Foreword 1 Issue 01

V Range 501 ●651 ●801 - Operator’s Guide

FOREWORD

The Johnston V501, 651 and 801 range of Suction Sweeper represents the highest grade of

craftsmanship and reliability that makes Johnston probably the world leader in sweeping technology.

This machine is designed for the removal of spoil on traffic or pedestrian areas, and litter collection

using the Wanderhose [Ref. EN 13019], and should only be driven by trained operatives.

This machine should not be used for sweeping hot or burning substances. In the unlikely event of

a fire, normal powder or foam fire fighting equipment can be used on this product.

An operator should receive training in the follow elements:

1 Safety Observations/Notices

2 Transit driving

3 Correct use of body prop

4 In cab controls

5 External controls

6 Sweeping techniques

7 Load discharge

8 Channel brush setting and changing

9 WSB setting and changing

10 Nozzle setting and Maxigap operation

11 Daily and weekly maintenance items

12 Driving/operation assessment

13 End of day cleaning of body and machine

Johnston Sweepers Limited can provide operator training upon request.

We would point out that it is the employers responsibility to carry out his own Risk Assessment on

the equipment in his particular working environment and work application.

This handbook should be carefully studied. In it you will find instructions for the operation and

maintenance of your JOHNSTON SWEEPER.

It is vitally important that the operator and maintenance staff have a copy of this book. The life of

the machine will depend upon following these instructions in respect of regular maintenance and

correct operating methods.

It is important that only GENUINE JOHNSTON SPARE PARTS are used when servicing and

maintaining the sweeper. This is especially important for consumables, filters etc, as the use of

non-genuine parts may cause premature failure and invalidation of warranty.

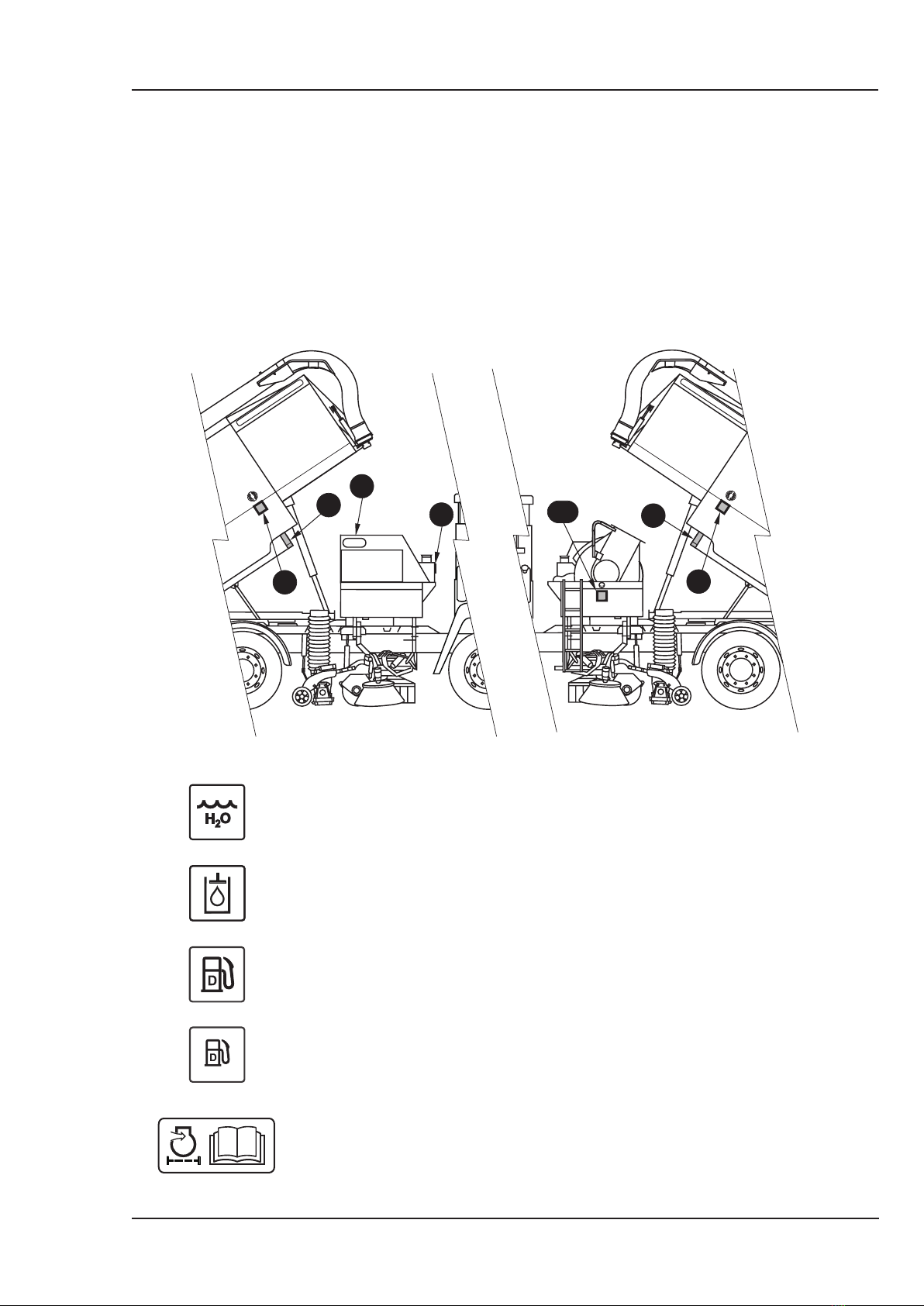

When carrying out maintenance or part replacement, additional explanatory illustrations can be

found in the Parts Manual, which shows and lists hardware, and availability of spares with the

orientation and positions of the various components.

All Copyright and rights are the property of Johnston Sweepers Ltd