3

SAFETY RULES

WARNING: When using gardening

appliances, basic safety precautions should al-

ways be followed to reduce the risk of fire and

serious injury. Read and follow all instructions.

This power unit can be dangerous! Operator is

responsible for following instructions and warn-

ings on unit and in manual. Read entire instruc-

tion manual before using unit! Be thoroughly fa-

miliar with the controls and the proper use of the

unit. Restrict the use of this unit to persons who

read, understand, and follow instructions and

warnings on unit and in manual. Never allow

children to operate this unit.

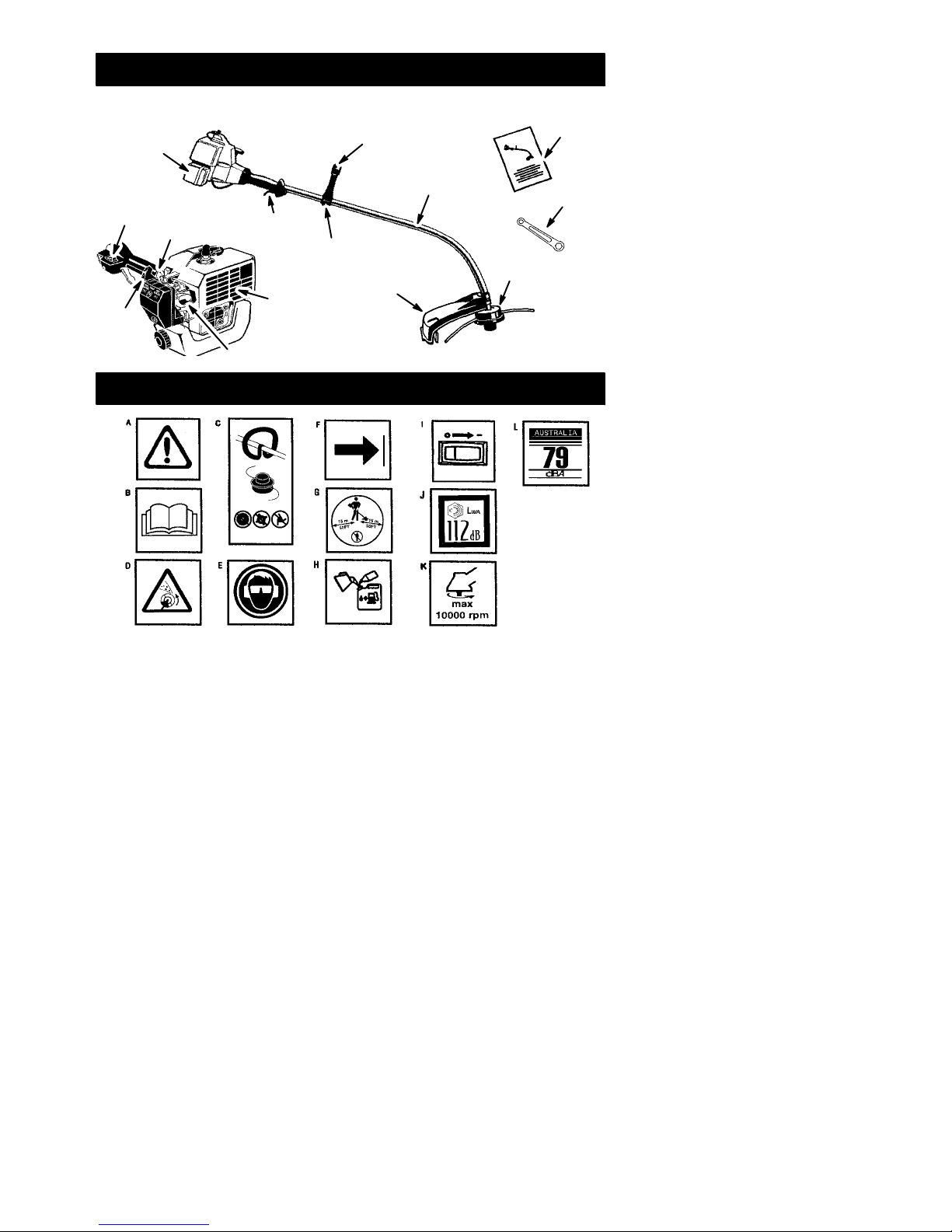

SAFETY INFORMATION

ON THE UNIT

INSTRUCTION

MANUAL

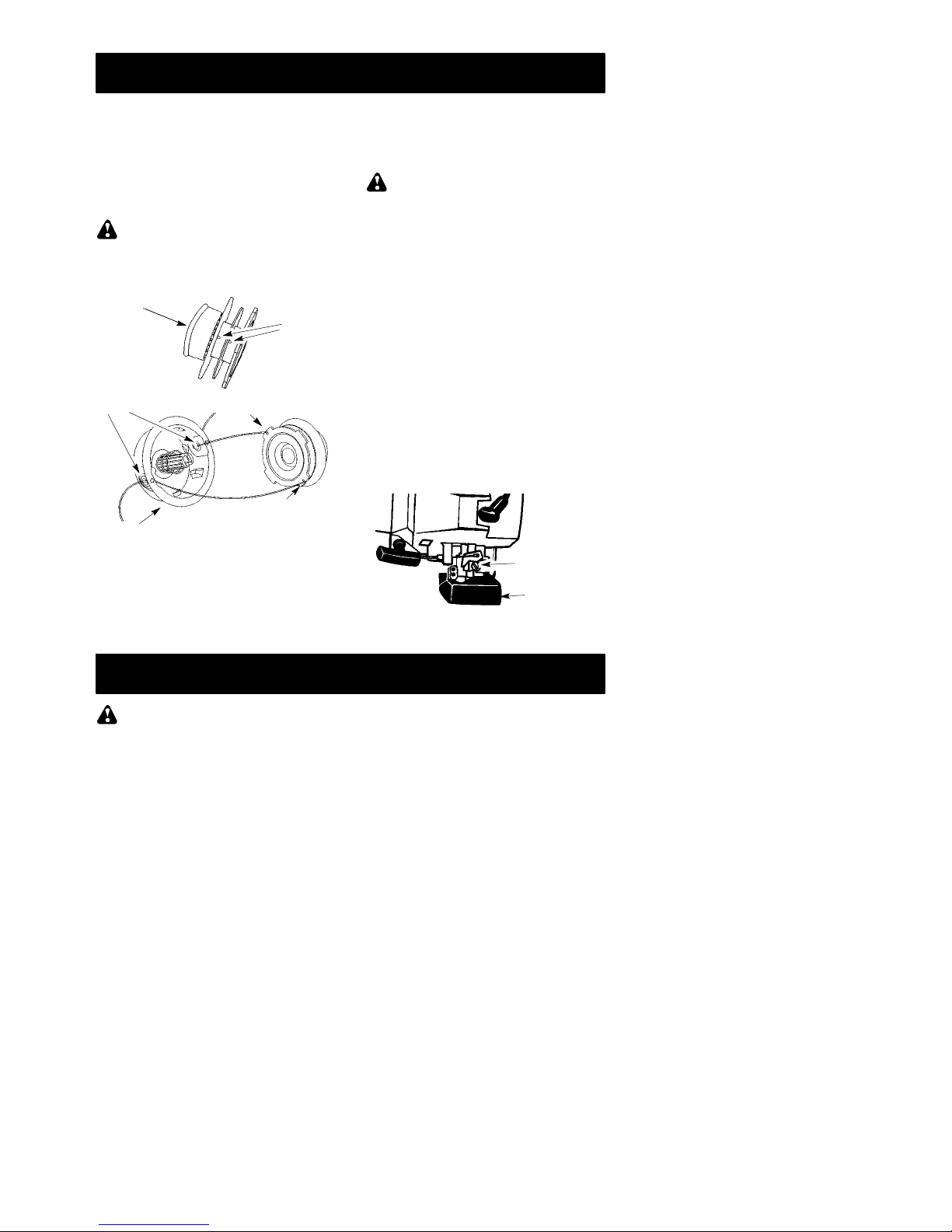

DANGER: Never use blades, wire, or

flailing devices. This unit is designed for line

trimmer use only. Use of any other accessories

or attachments will increase the risk of injury.

WARNING: Trimmer line throws ob-

jects violently. You and others can be blinded/

injured. Wear safety glasses and leg protec-

tion. Keep body parts clear of rotating line.

Safety Glasses or similar eye protection

Boots

Hazard Zone

15 meters

Keep children, bystanders, and animals 15 me-

ters away. If approached stop unit immediately.

If situations occur which are not covered in

this manual, use care and good judgement. If

you need assistance, contact your authorized

service dealer.

OPERATOR SAFETY

SDress properly. Always wear safety

glasses or similar eye protection when op-

erating, or performing maintenance, on

your unit (safety glasses are available).

Eye protection should be marked Z87.

SAlways wear face or dust mask if operation

is dusty.

SAlways wear heavy, long pants, long

sleeves, boots, and gloves. Wearing safety

leg guards is recommended.

SAlways wear foot protection. Do not go

barefoot or wear sandals. Stay clear of

spinning line.

SSecure hair above shoulder length. Secure

or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc.

They can be caught in moving parts.

SBeing fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

SStay Alert. Do not operate this unit when you

are tired, ill, upset or under the influence of al-

cohol, drugs, or medication. Watch what you

are doing; use common sense.

SWear hearing protection.

SNever start or run inside a closed room or

building. Breathing exhaust fumes can kill.

SKeep handles free of oil and fuel.

UNIT / MAINTENANCE SAFETY

SDisconnect the spark plug before performing

maintenance except carburetor adjustments.

SLook for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep in good working

condition.

SReplace trimmer head parts that are

chipped, cracked, broken, or damaged in

any other way before using the unit.

SMaintain unit according to recommended

procedures. Keep cutting line at proper

length.

SUse only 2 mm diameter Jonsered®brand

line. Never use wire, rope, string, etc.

SInstall required shield properly before using

the unit. Use only specified trimmer head;

make sure it is properly installed and se-

curely fastened.

SMake sure unit is assembled correctly as

shown in this manual.

SMake carburetor adjustments with lower

end supported to prevent line from contact-

ing any object.

SKeep others away when making carburetor

adjustments.

SUse only recommended Jonsered®acces-

sories and replacement parts.

SHave all maintenance and service not ex-

plained in this manual performed by an au-

thorized service dealer.

FUEL SAFETY

SMix and pour fuel outdoors.

SKeep away from sparks or flames.

SUse a container approved for fuel.

SDo not smoke or allow smoking near fuel or

the unit.

SAvoid spilling fuel or oil. Wipe up all fuel spills.

SMove at least 3 meters away from fueling

site before starting engine.

SStop engine and allow to cool before re-

moving fuel cap.

SAlways store gasoline in a container ap-

proved for flammable liquids.