Date:

Manual:

Rev:

2020-02-04

M395

F2

JOWA Ag-S

Silver Ion Water Treatment System

Standard

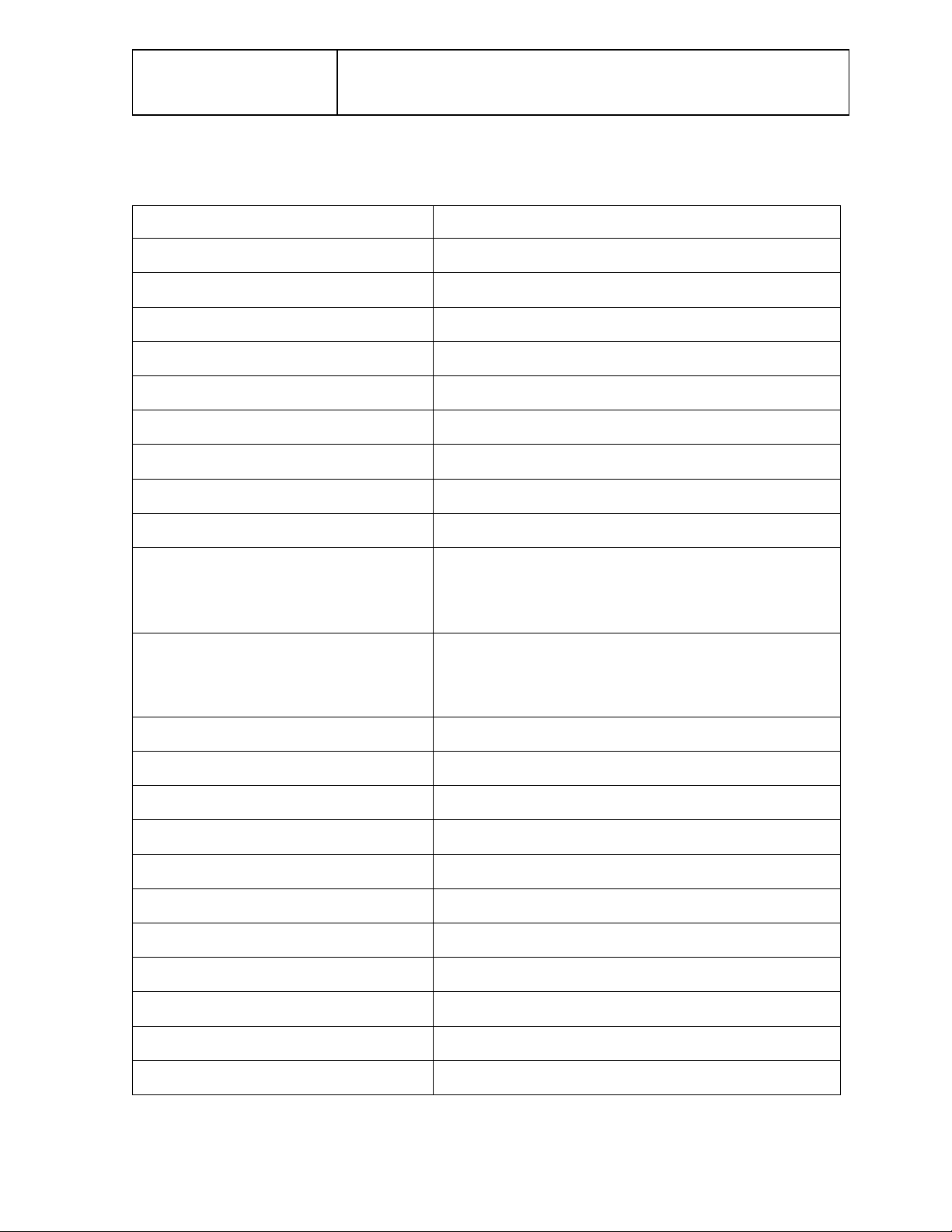

Table of Contents

1.0 Introduction............................................................................................ 1

1.1 General ................................................................................................ 3

2.0 Technical Specification......................................................................... 4

3.0 Treatment of Water................................................................................ 5

3.1 Standard Installation – Tank Recirculate Mode.................................... 5

3.2 Direct Flow Mode ................................................................................. 6

3.3 Options................................................................................................. 6

4.0 Installation.............................................................................................. 7

4.1 Mounting .............................................................................................. 7

4.2 Piping Connections .............................................................................. 7

4.3 Electrical Connections.......................................................................... 8

4.4 Typical connections.............................................................................. 9

5.0 Operation................................................................................................ 9

5.1 Start Up................................................................................................ 9

5.1.1 Tank Recirculate Mode ...................................................................... 10

5.1.2 Direct Flow Mode ............................................................................... 10

5.1.3 Final Setup......................................................................................... 11

5.2 Operating the Menu System .............................................................. 11

5.3 Operating Modes................................................................................ 12

5.4 The Menu Structure ........................................................................... 13

5.4.1 Water System Tank Size Entry .......................................................... 16

5.4.2 Watermaker Flow Rate Entry (Optional – when using a watermaker) 16

5.4.3 Setting Final Silver Dosage Level ...................................................... 17

5.4.4 Set Volume for Flowmeter pulse (Optional – when using flowmeter). 17

5.4.5 Flush water through system – when solenoid valve installed............. 17

5.4.6 Setup Relays (Optional – when using outputs) .................................. 18

5.4.7 Select Direct Flow Mode .................................................................... 18

5.4.8 Setup Input for Direct Flow................................................................. 18

5.5 Error List ............................................................................................ 19

5.6 Replacement of the Electrode............................................................ 21

5.7 Maintenance ...................................................................................... 22

5.8 Flash Pattern for Power LED ............................................................. 22

6.0 Trouble Shooting................................................................................. 23

6.1 Resetting the Ag-S ............................................................................. 25

7.0 Spare Parts List ................................................................................... 26

8.0 Flow Diagrams ..................................................................................... 27

9.0 Mechanical Drawings .......................................................................... 29

10.0 Electrical Drawings.............................................................................. 30

11.0 Additional Items................................................................................... 31