JP-33 SERVICE MANUAL

- -

9

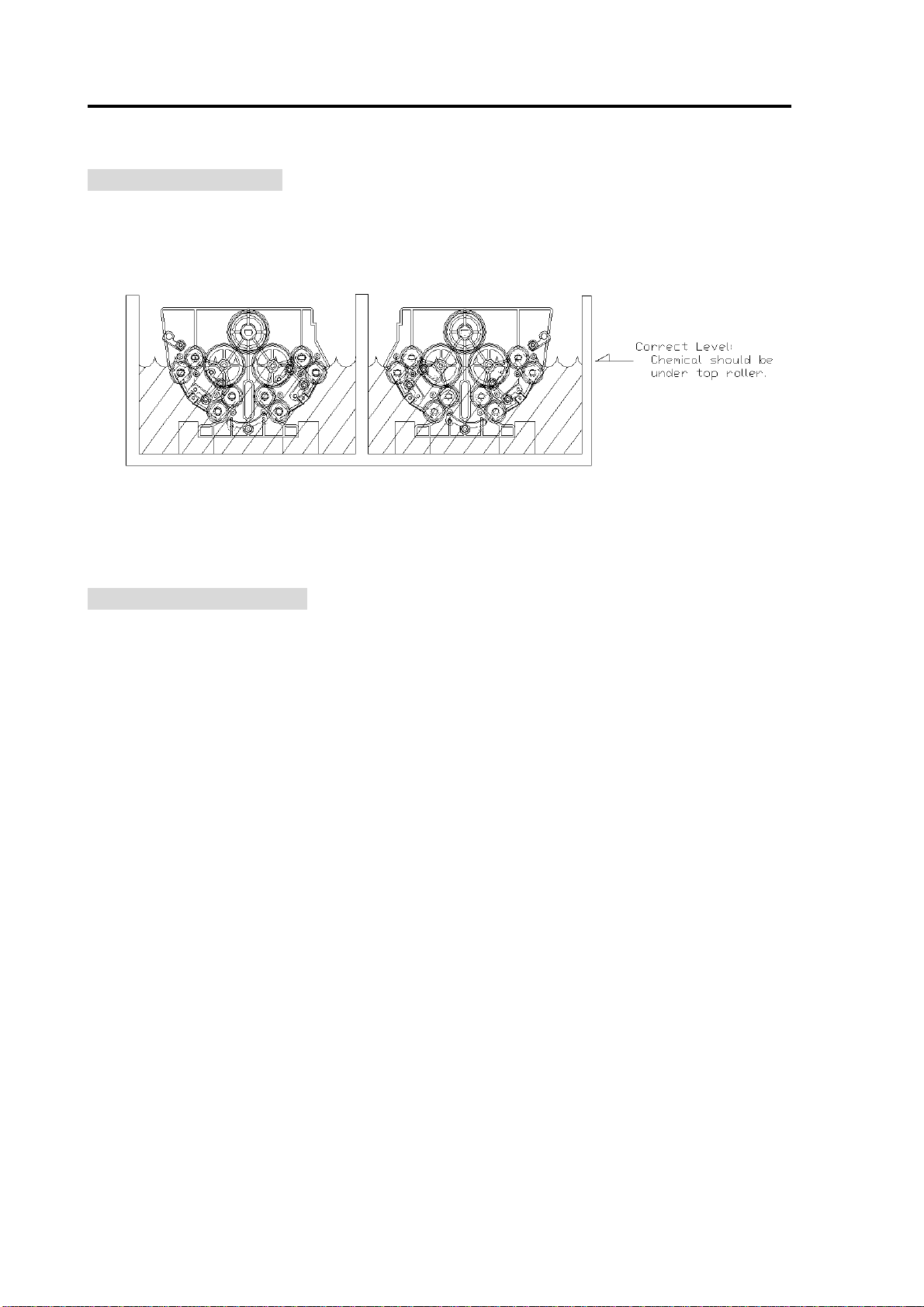

MaintenanceProgram - Checking and Inspect

Monthly Inspection

1. Check the hoses, clamps and plumbing

-Do not tighten the hose clamps too much. Clamps that are too tight may cut hose and cause leakage,

which may result in damage to pumps and electrical components.

-Check hose for kinks or cracks.

2. Check lubricated parts

Remove old lubrication and apply new lubrication for appropriate parts in accordance with the oiling

schedule.

A. Remove old lubricant

Old lubricant should be removed before applying new fresh lubricant. The absorption of dust or

other foreign substances on the old lubricant may cause unwanted friction.

B. Cleaning

Before applying new lubricant, use a brush to remove any foreign material or pollutant from the

gears.

C. Lubricating pointer

Main drive shaft and Bracket Oil/Teflon oil

Worm Gear, Drive Gear Oil/Teflon oil

Main Motor Sprocket and Chain Grease

Annual Inspection

1. Check the RPL. Pump Valve

A. Unscrew the valve-fixing cap off the replenishment pump.

B. Remove the valve from the pump to prevent damage.

C. Soak the separated valve in warm water. Physically check the valve for pollutant.

D. Carefully place the clean and checked valve back into the pump. Make sure the valve is positioned

properly.

E. Screw the valve-fixing cap back onto pump.

F. Handling of the valve of RPL pump should be in strict accordance with the above

instructions and other instructions in this manual.

2. Check the worm drive and worm wheel (gear)

A. The worm drive and worm wheel (gear) are critical parts of the transport system. These two parts

are exposed to great pressure. Therefore, it is important to carefully examine the parts for wear

and tear.

B. Carefully check the worm drive and worm wheel (gear) for wear and tear, and replace the part when

needed.