JUDO BIOSTAT-COMBIMAT 5

About this Operating Instructions

1. About this Operating

Instructions

ATTENTION

(see chapter “Safety information and

dangers due to non-compliance”)

This users’ manual should always be kept

near the actual device in operation.

This instruction manual is intended to make

it easier to familiarize yourself with the water

treatment device and its possible intended

uses.

The instruction manual contains important

information required for the safe, correct and

economical use of the unit concerned.

It contains fundamental information, which

must be observed during installation, opera-

tion and maintenance. Observance of this

information helps to avoid dangers, reduce

repair costs and increase the reliability and

working life of the water treatment unit.

The instruction manual must be read and

used by each person entrusted with carrying

out work on the water treatment device, for

example:

– Installation

– Operation

–Maintenance

(servicing, inspection, repair)

Installation and maintenance may only be

carried out by personnel authorized by the

manufacturer, who are capable of fulfilling

the instructions given in the installation and

operating instructions and the country-

specific prescriptions.

Apart from the instruction manual and the

laws governing health & safety applicable in

the country and place of use, the recognised

technical regulations for safe and proper

work must also be observed.

Therefore, this instruction manual must

always be read by the fitter and responsible

skilled personnel/owner or operator before

installation, commissioning and mainte-

nance.

Not only the generalsafety notes given in

the chapter on “Intended Use”are to be

observed, but also the special safety

notes inserted under the other main

items.

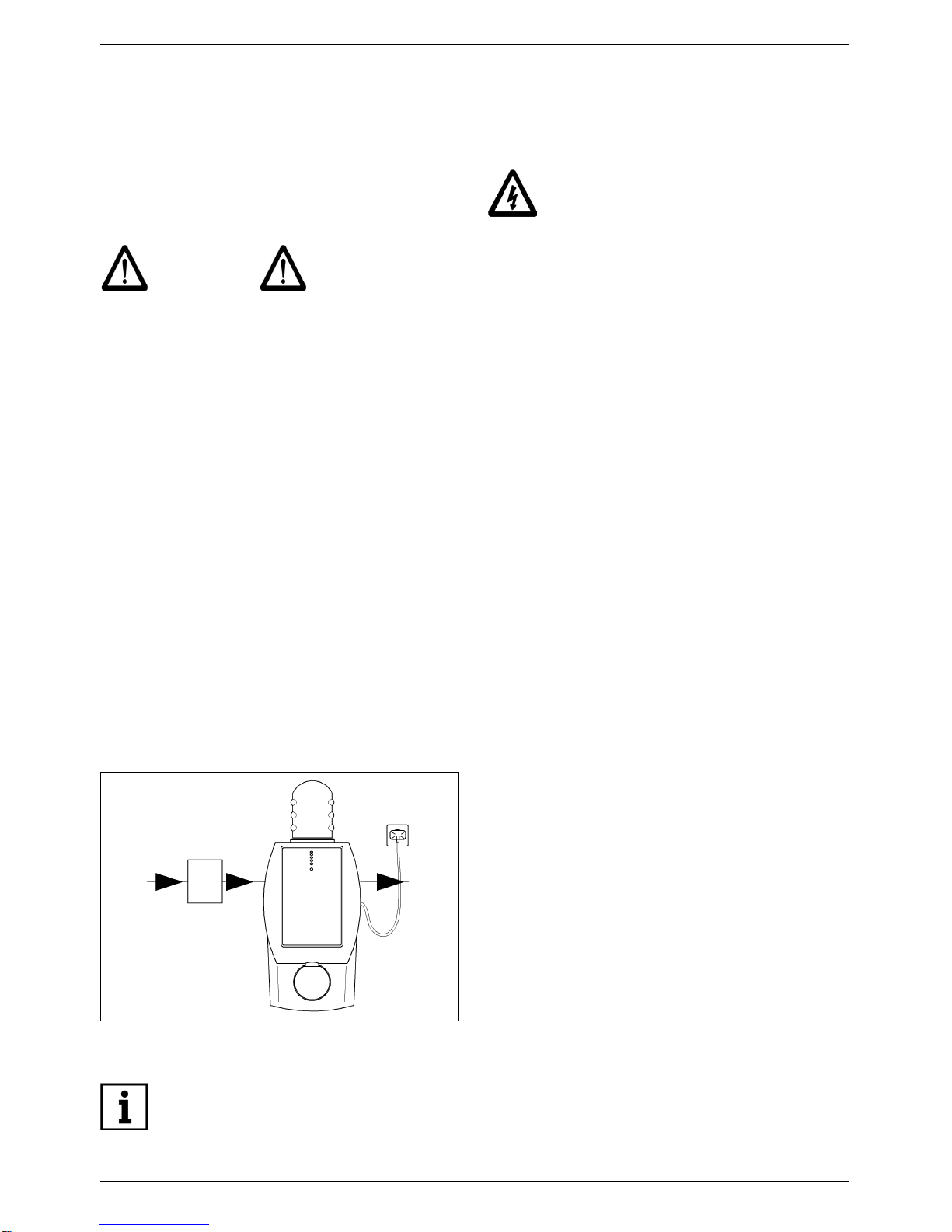

1.1 Symbols used

The safetynotes contained in thisinstruction

manual are labelled with the following

symbols:

Notes directly attached to the water treatment

device, e.g.:

– Direction of flow (see Fig. 1)

– Type plate

– Cleaning information

must always be observed and kept in a fully

legible condition.

ATTENTION Notes on existing

dangers

Warning, electrical voltage

Torques specified by the

manufacturer.

Tips for use and other

information.

Fig. 1: Built-in rotary flange