CONTENTS

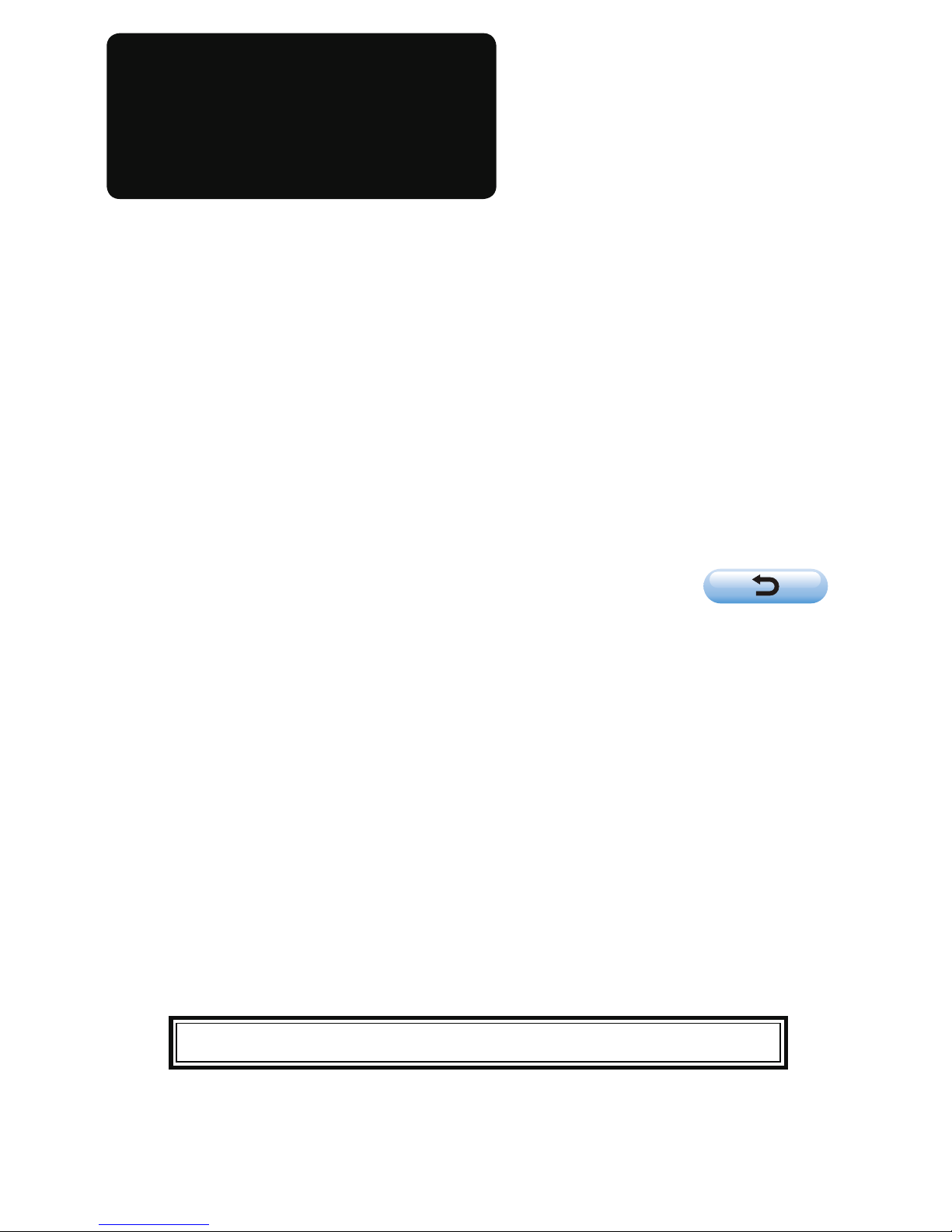

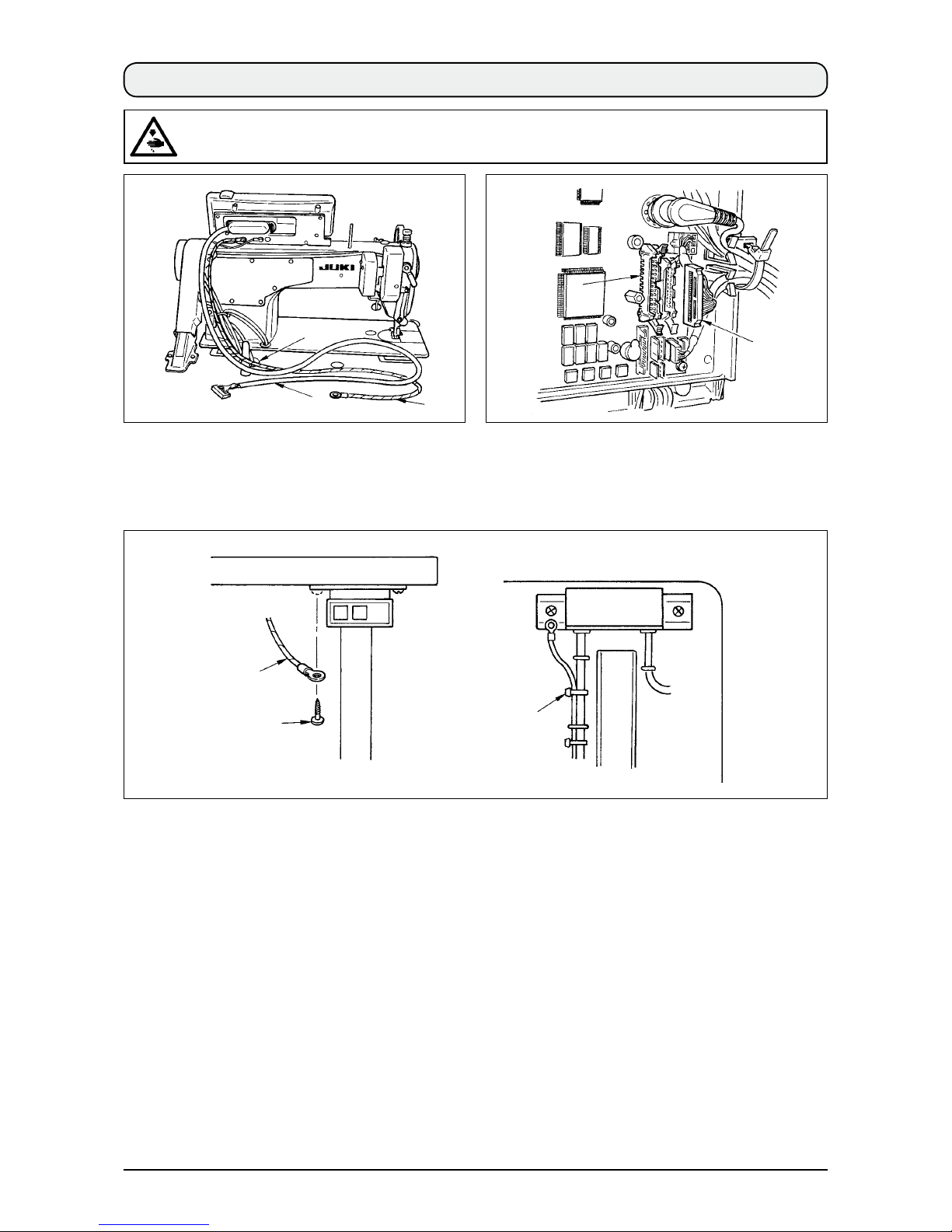

1. INSTALLING THE OPERATION PANEL................................................................... 1

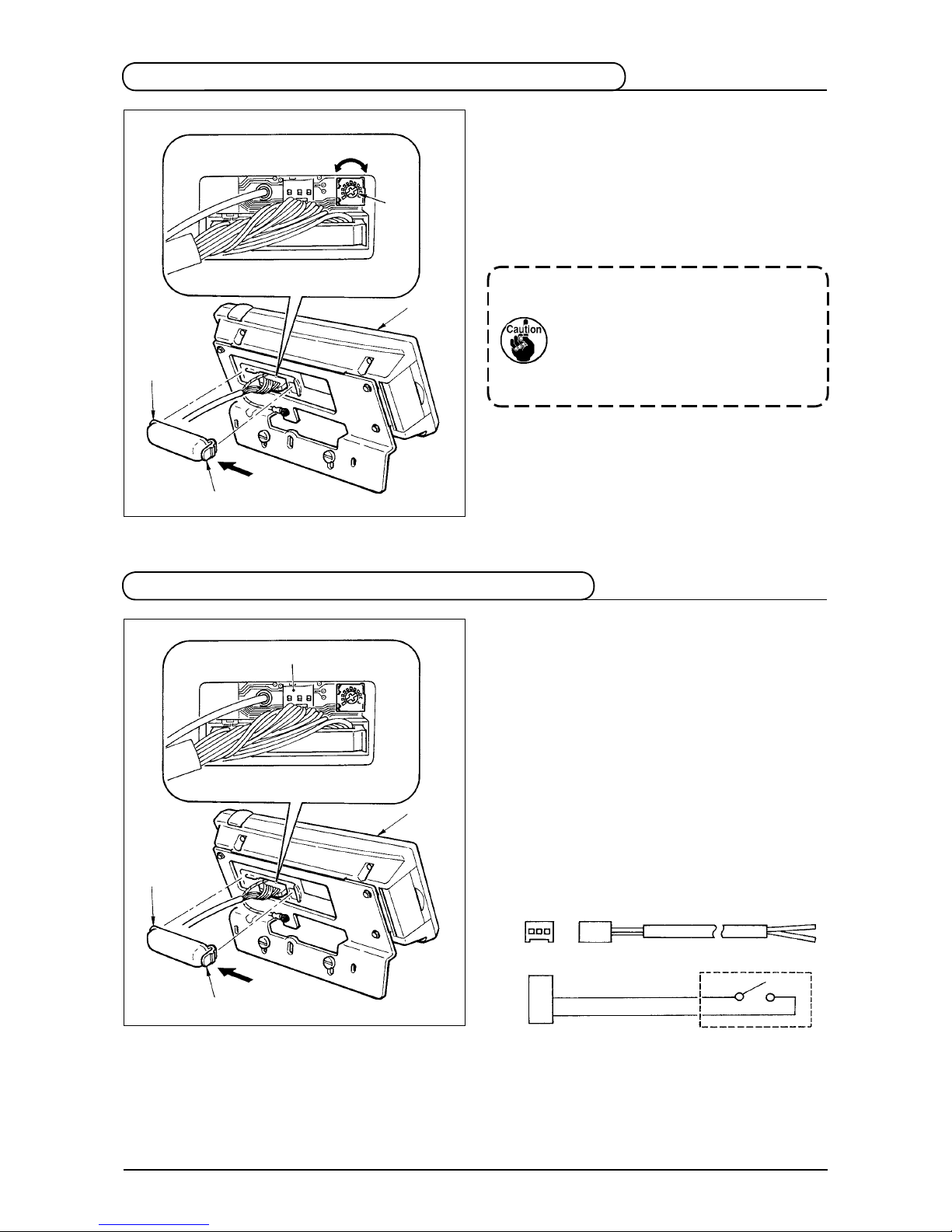

2. CONNECTING THE CORD........................................................................................ 2

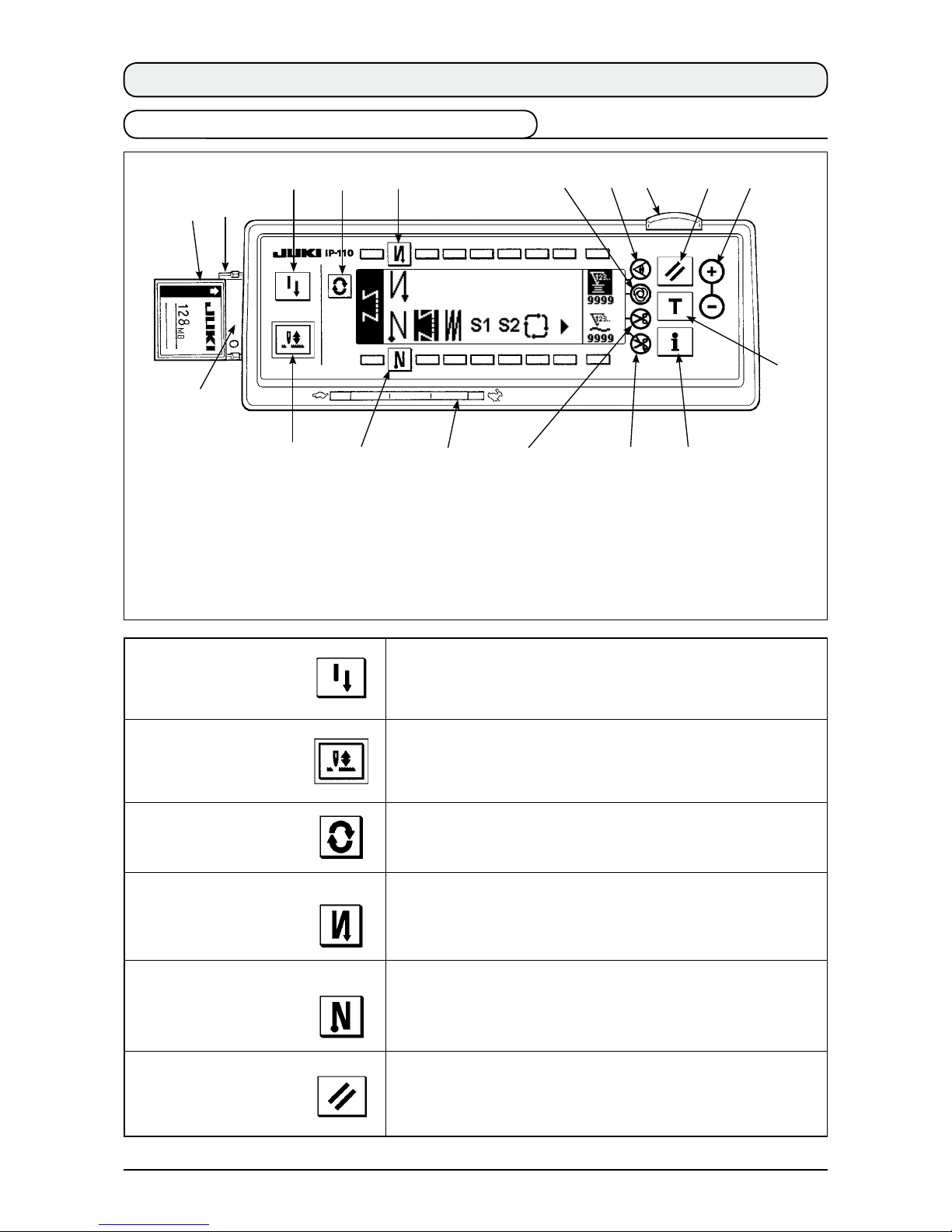

3. HOW TO USE THE OPERATION PANEL ................................................................. 3

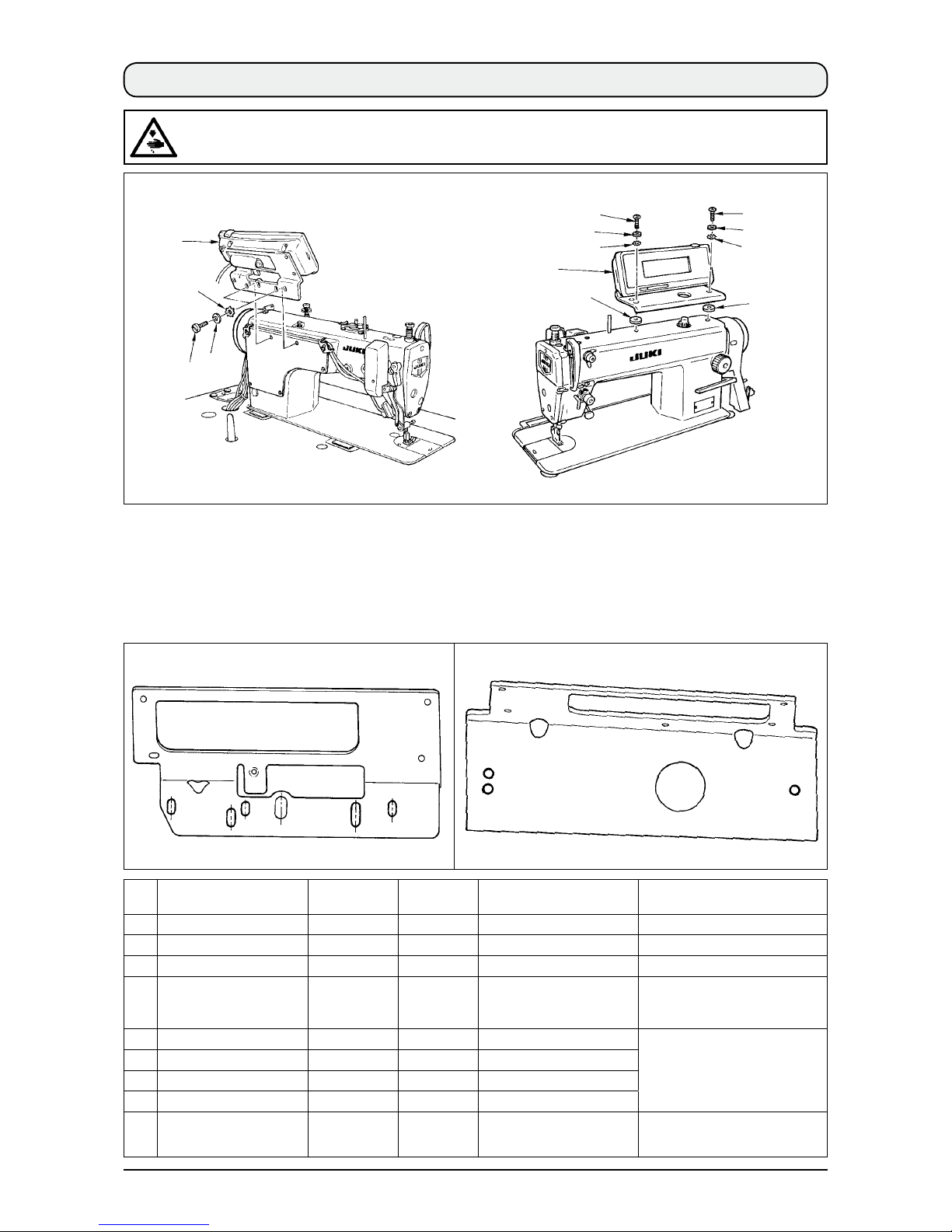

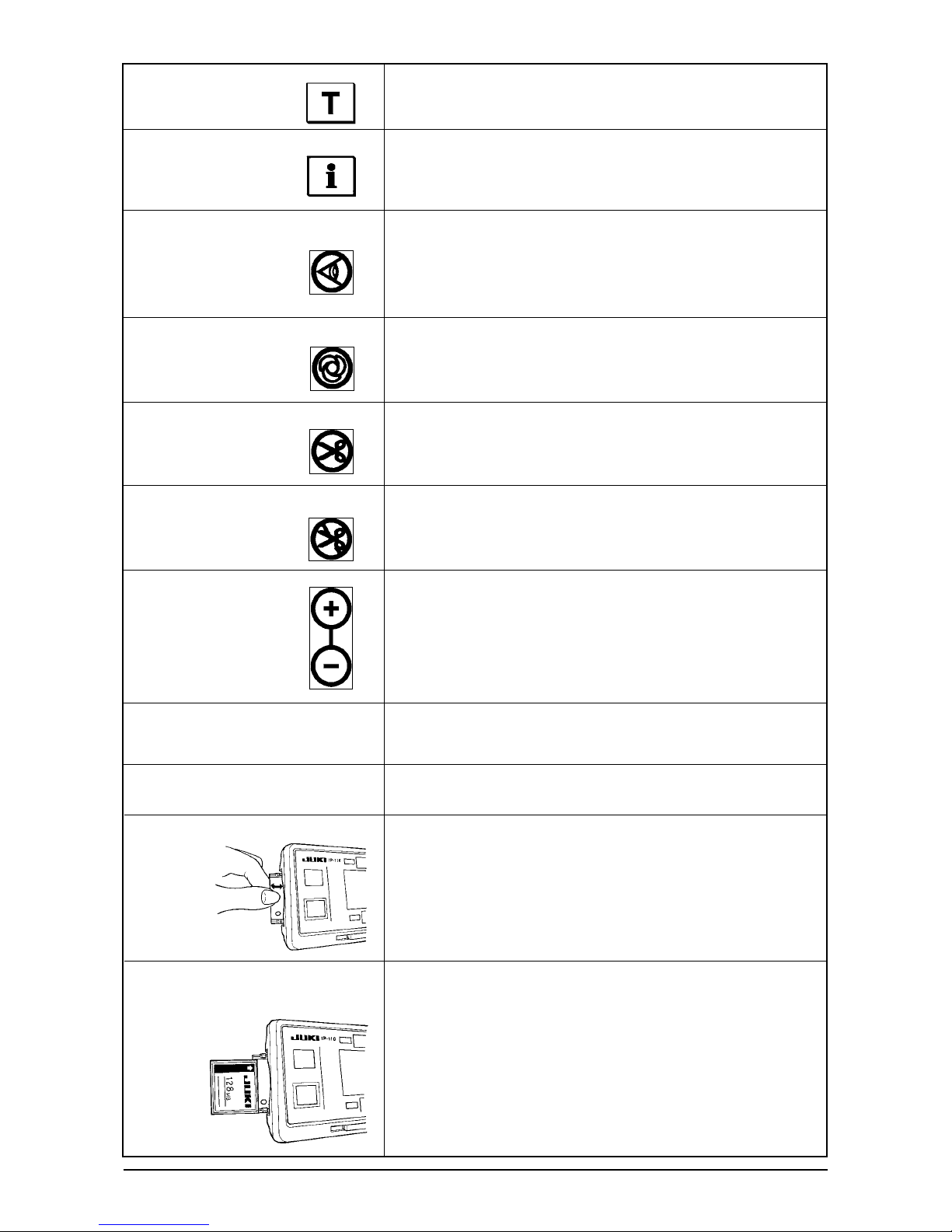

3-1. Names and functions of each components .....................................................3

3-2. Adjusting the contrast of the operation panel display....................................5

3-3. Production control switch connecting connector...........................................5

4. STANDARD PANEL................................................................................................... 6

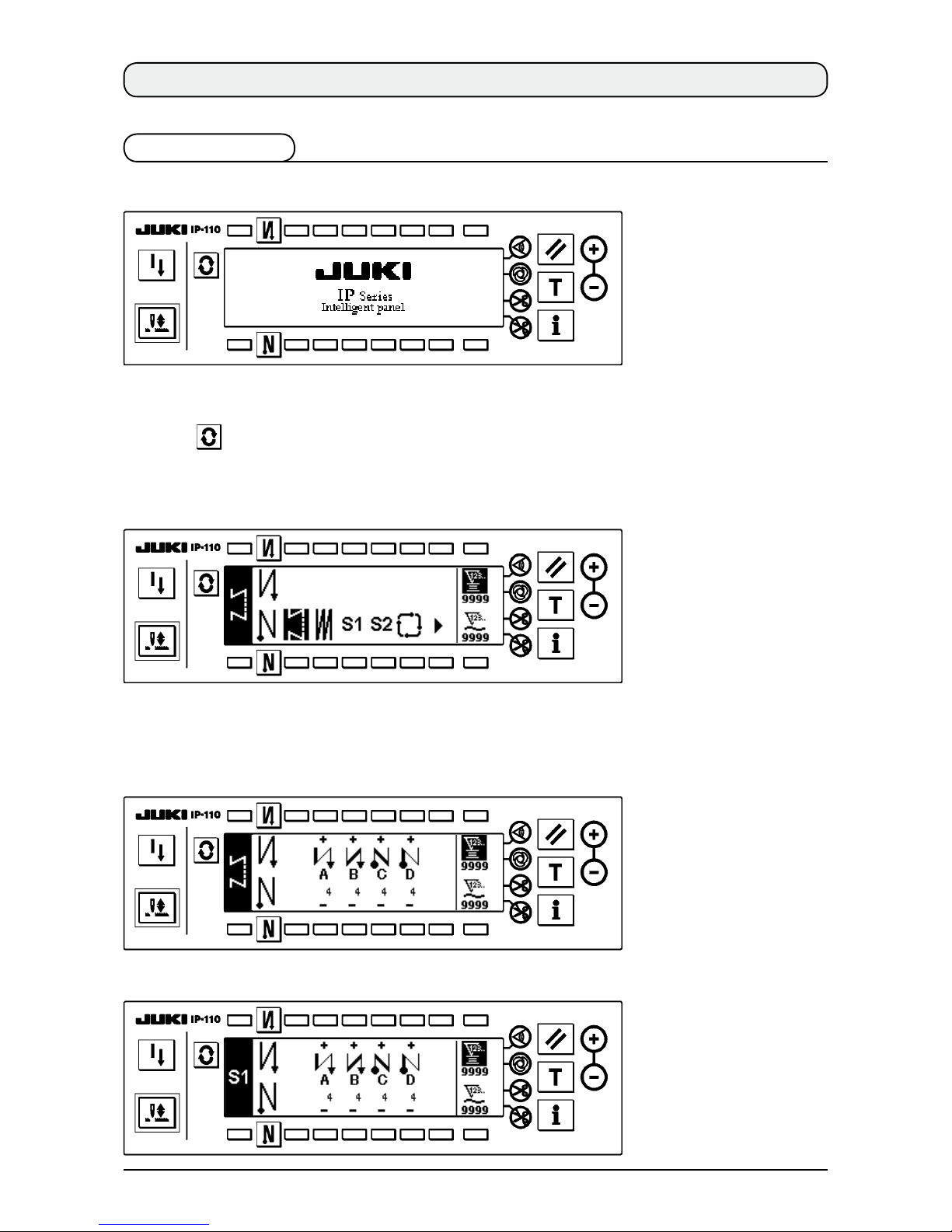

4-1. Basic screen........................................................................................................6

4-2. How to operate the operation panel for sewing stitching patterns ...............8

(1) Reverse stitching pattern...................................................................................................................8

(2) Overlapped stitching pattern ...........................................................................................................10

(3) Programmed stitching pattern......................................................................................................... 11

(4) Cycle sewing pattern ........................................................................................................................15

4-3. How to use the bobbin thread counter ...........................................................17

4-4. No. of pcs. counter ...........................................................................................18

4-5. Re-sewing switch..............................................................................................18

4-6. Needle up/down compensation switch...........................................................19

4-7. ON/OFF switch of the material edge sensor.............................................19

4-8. Automatic thread trimming switch ............................................................19

4-9. One-shot automatic stitching switch ........................................................19

4-10. Thread trimming prohibition switch ........................................................20

4-11. Key lock ...........................................................................................................20

4-12. Information ......................................................................................................21

(1) Maintenance management function................................................................................................21

(2) Production control function.............................................................................................................25

(3) Working measurement function ......................................................................................................27

4-13. Setting for functions.......................................................................................29

(1) How to change over to the function setting mode ........................................................................29

(2) Function setting list..........................................................................................................................32

5. PANEL FOR LH-4168/4188 ..................................................................................... 37

5-1. Basic screen......................................................................................................37

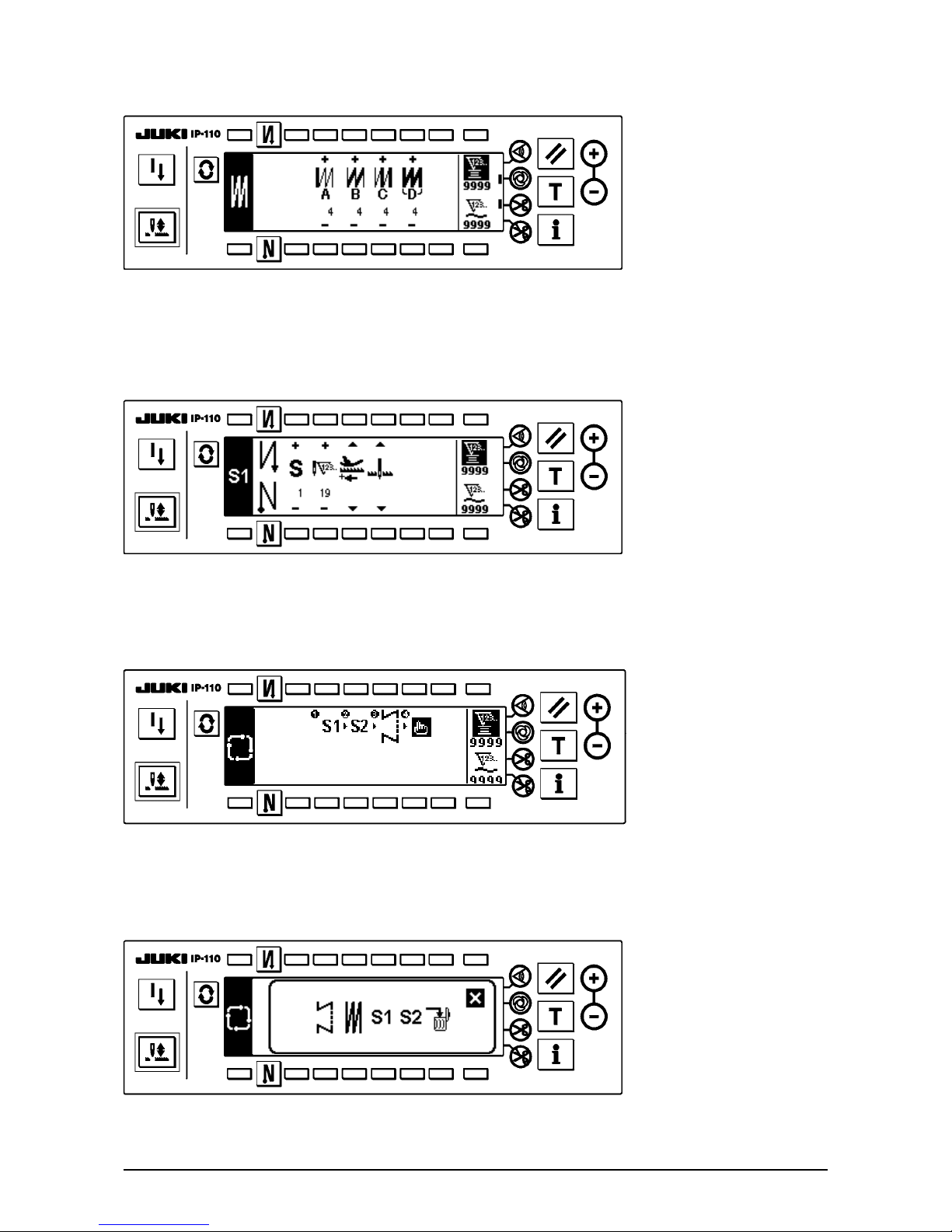

5-2. How to operate the operation panel for sewing stitching patterns .............41

(1) Reverse stitching pattern.................................................................................................................41

(2) Overlapped stitching pattern ...........................................................................................................43

(3) Corner pattern ...................................................................................................................................44

(4) Step pattern .......................................................................................................................................50

(5) Cycle sewing pattern ........................................................................................................................53

5-3. How to use the bobbin thread counter ...........................................................54

5-4. No. of pcs. counter ...........................................................................................55

5-5. Re-sewing switch..............................................................................................56

5-6. Needle up/down compensation switch...........................................................57