– 1 –

1

2

43

3

2

5

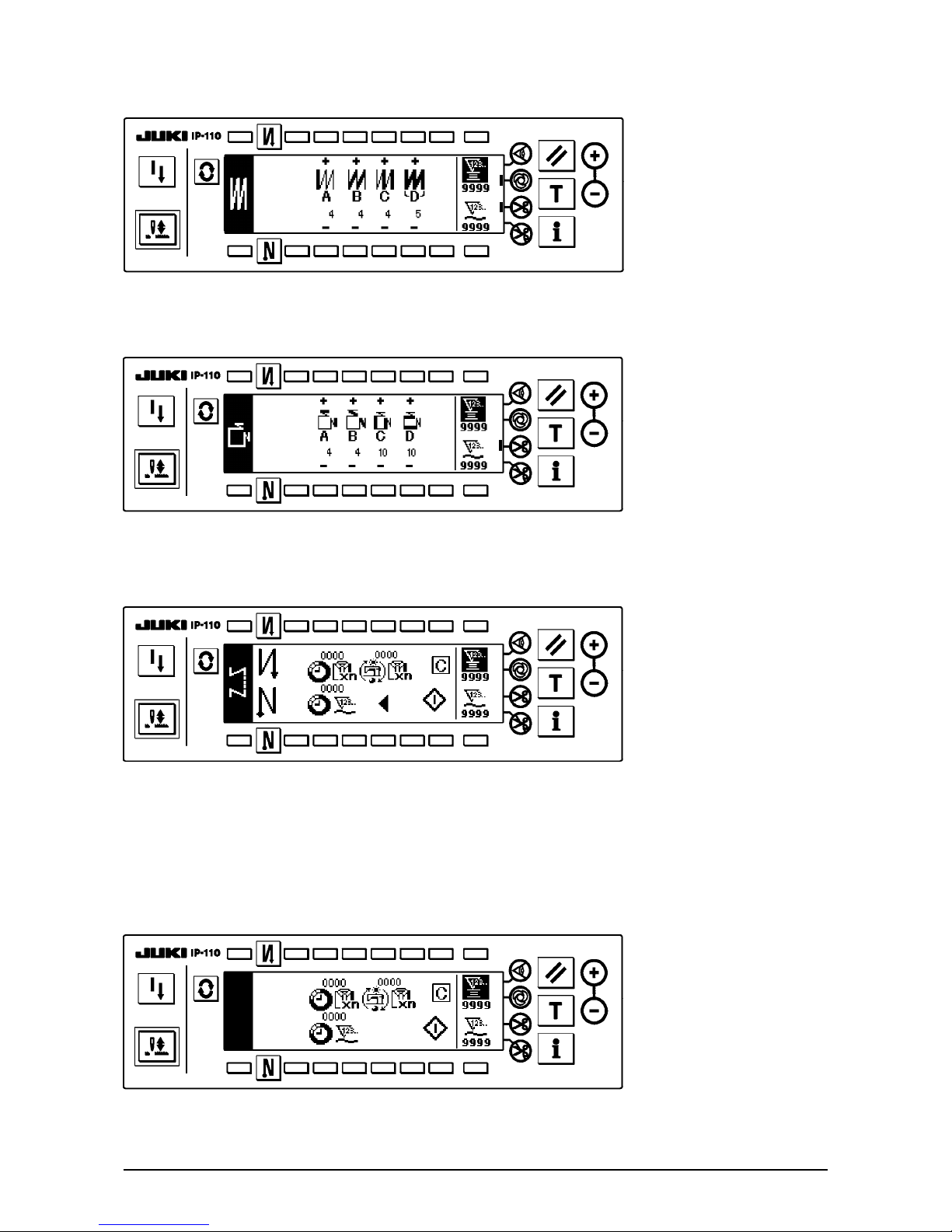

1. SETUP OF HARDWARE

45˚

CN41

CN121

1-1. Installing IPOP circuit board

IPOP circuit

board

2) Set the panel cord same as the other machine

head cords, insert it to CN121 of the control box,

and lock it.

3) Put it together with other machine head cords and

bundle them with clip band 5.

4) Close the front cover and tighten two screws,

while taking care not to put the cords in the front

cover.

1-2. Installing the panel

Refer to Instruction Manual for SC-510 together with this Instruction Manual.

WARNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after turning OFF

the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specifications, be sure to connect all the

corresponding connectors to the specied places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied with the

devices before handling the devices.

1) Install operation panel 1on the machine head

using screws 2, washers 3and spring washers

4supplied as accessories.

Do not disassemble the operation panel to

prevent it from breakage.

1) Loosen two screws in the front cover of control

box and open the front cover.

2) Remove connectors and ground wire of the circuit

board attached to the front cover.

3) Place the front cover at an angle of approximate

45°, draw it in the direction of arrow, and remove

it from the box main unit.

Do not draw the front cover forcibly since

there is the possibility that the click of front

cover is broken.

4)

Securely insert CN41 of IPOP circuit board supplied

as accessories to white connector CN41 on the

front cover circuit board from the upper side.

5) Fix IPOP circuit board with two screws 1supplied

as accessories.

6) Place the front cover at an angle of approximate

45°, attach it to the box main unit, and attach

connectors and ground wire which have been

removed in step 2).

When removing IPOP circuit board, turn

OFF the power and remove it after 5 minutes

or more have passed.

11

4