(

3.

J:~~b

1±1

l,:IIO)~~

I Adjusting the needle thread feeding amount)

(J::~O)*ai1JI;:~,!¥~f!i~NO)~t1i:t.J'

SO)~~IJ

~(!1il:~m

L.,

a;-g

o~0)~~1il:EIB'ilt:

L.,:J;9

o)

(Length

of

the remaining thread from needle eyelet required at a minimum

of

amount

to

knot

the

needle thread can be adjusted. It

is

purposed

to

reduce the

bird's

nest.)

6~~~

1'

!\

0)

i!il!WJ

I;::

J;

7.>

lfl;ll(

1d:

llJj

<'

~,

ill!ii!!lhHf, I

7'

-{mg

1d:

t;JJ

!J

, ililliJ"'

$'I

It

1d:

WJ!

A;c

1:J

iWJ

INJ:

i.:E,~,

~

lt\:li..~c!'i'::>

L"

<tee~

lo

~

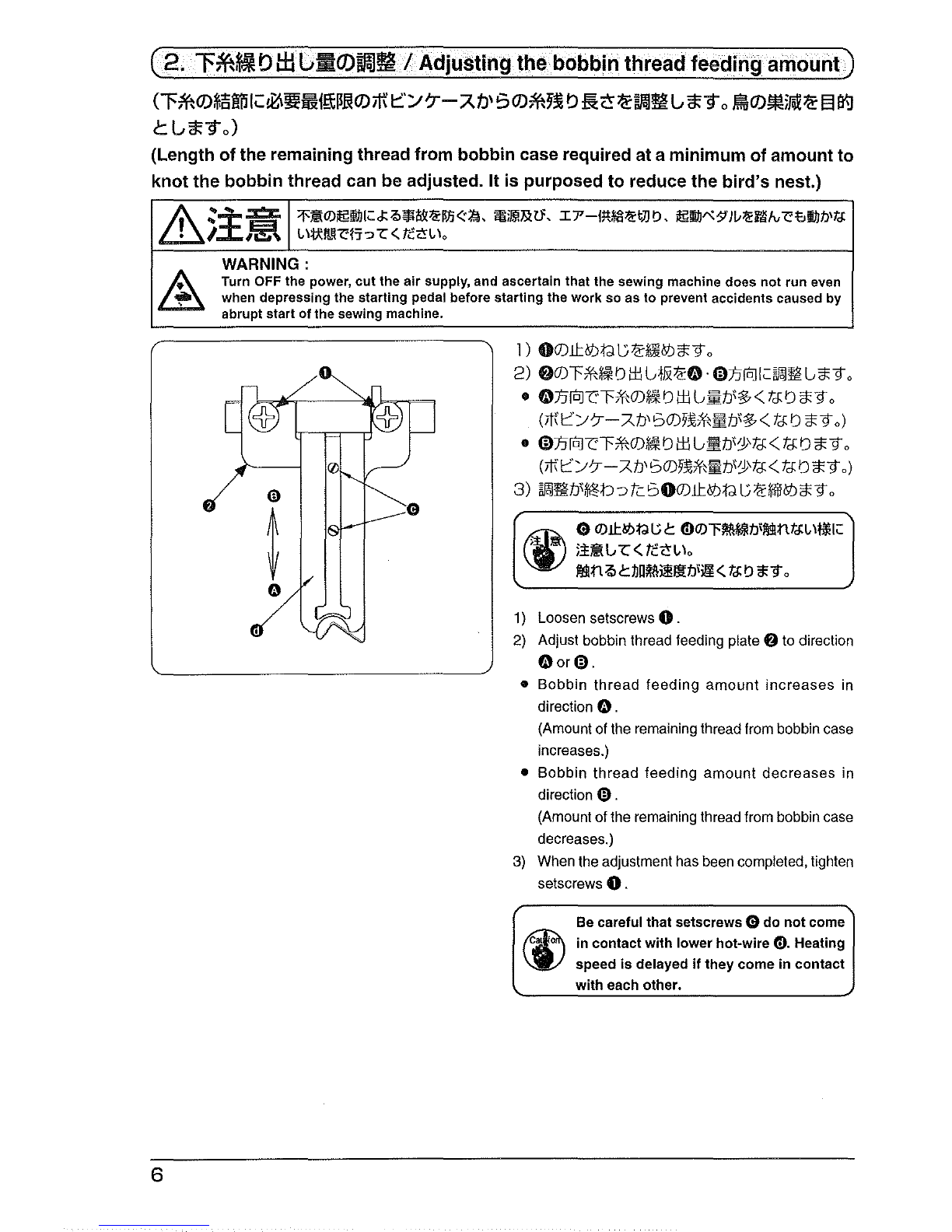

WARNING:

Turn OFF the power, cut the air supply, and ascertain that the sewing machine does not run even

when depressing the

starling

pedal before starling the

work

so as to prevent accidents caused by

abrupt start of the sewing machine.

1)

_t;'fdi\~1)

:±J

l/1

IJ

Y5'-0Y::Z

i'

~

J\-'li!JOJ,j:'.FcttJlG

r:l1iP!

o

2)

_t;<r-~1)

:±J

G&I<::J::oiltfR€)0)~1)

:±J

Gl!;},j:!ii&'6G2109

o (0=31

mm

cilti'R?'\11)

lEI<t

18

mm

ilil£il

3)

iltfR@O)~I):±J

Gl!;},j:~<

9-QI<::I<:t,

DO)lfEiiJltl,j:~<

G*9

o

'tO)~,

00)7

~

i--},j:*~<lb01,j:1J:"-@l

G*

9o

:!-'IJ:<9o~1§ll<t,

~I<::@JG2109o

00)lfE1illtb'i:R210::>/cSOcOJ,j:ll'iJ/EG2109o

4)

!tltBO)j]j,'~l<::litl

lJC::,

_t;<r-~1)

:±J

G@O)itr:,~~O))'c!llitj

C:::!tltll.LITDOb'SO)lfEijl.},j:!iii¥

G2109

o

'5tJO:fl<::,

I~:±Jfof~l<t,

iltt&.LIT!ib'

SO)""~

H =12

mm

},j:§'§'I<:::±Jfoj

G

C::t,

12109

o

*9\

00)lt<lbofdl5

2

;$:1,j:*~<lb,

00)J.!!Zf1iO},j:_tT~mG,

ff~"'"e

H

},j:~li:!EG2109o

it£il<::00)ofdlJ},j:IQJ/EG2109o

tJ<[),

01<t,

:t7Y

=00)=-

r%?-5-ll'iJIEJ!:Rlofdl5c9o

5)

::'RI<::,

00)J.!!Z{1iO},j:_tT~mG/cL:C:::I<::J::

I),

iltfR@O)~I):±J

GlEb'?ltbI)

21090)c,

00)lt<lbofd

l5

4

:$:1<::-c_t;<r-~l)

:±J

Vii\'ili[j:{:i;},j:_t

T~mG2109

o

*

01,j:'.Fcl1Jl

G

l:"Ab-

A"I<::.L

Tt!J9oL:C:::},j:!ii&'6GtJb'S.L

T~m},j:fJ'::>

l:

</eel

lo

'E-0)~1<::51

::>lifb'I)

b'®o~;§';l<t,

0C:::00)lt<lbofd

c;

1<::-c~m<

/eel

10

1)

Press down by hand stopper shaft 0 of the needle thread feeder cylinder.

2)

Check the feeding amount of needle thread 9 by needle thread feeder

f)

.

(In

case of 0=31 mm, the remaining amount of needle thread is approximately

18

mm.)

3)

To increase the remaining amount of needle thread, increase the distance of

D.

At

this time, loosen nut 0 and turn

it counterclockwise. To decrease

it,

turn the nut clockwise. When the distance 0 is determined, fix 0 with 0 .

4)

Secure the distance from the top end of needle thread feeder

f)

when it is in the lowest position to top surface 0

of the material in accordance with the thickness of the material.

Incidentally, the height from the top surface of throat plate H is set to

12

mm as standard at the time of delivery

from the factory.

First, loosen two setscrews

0,

adjust installing base 0 by moving it up or down, and set the optional height

H.

Finally, tighten setscrews

0.

In addition, 0 are screws used both for setting the installing base and for fixing the

optional needle cooler.

5)

Next, adjust the whole needle thread feeder unit with four setscrews 0 by moving it up or down since the feeding

amount of needle thread 9 changes by adjusting installing base 0 by moving it up or down.

* Press 0 by hand and check that it smoothly moves up or down

to

perform the up/down adjustment. At this time,

when it does not move smoothly, adjust it with setscrews 0 and

0.

7