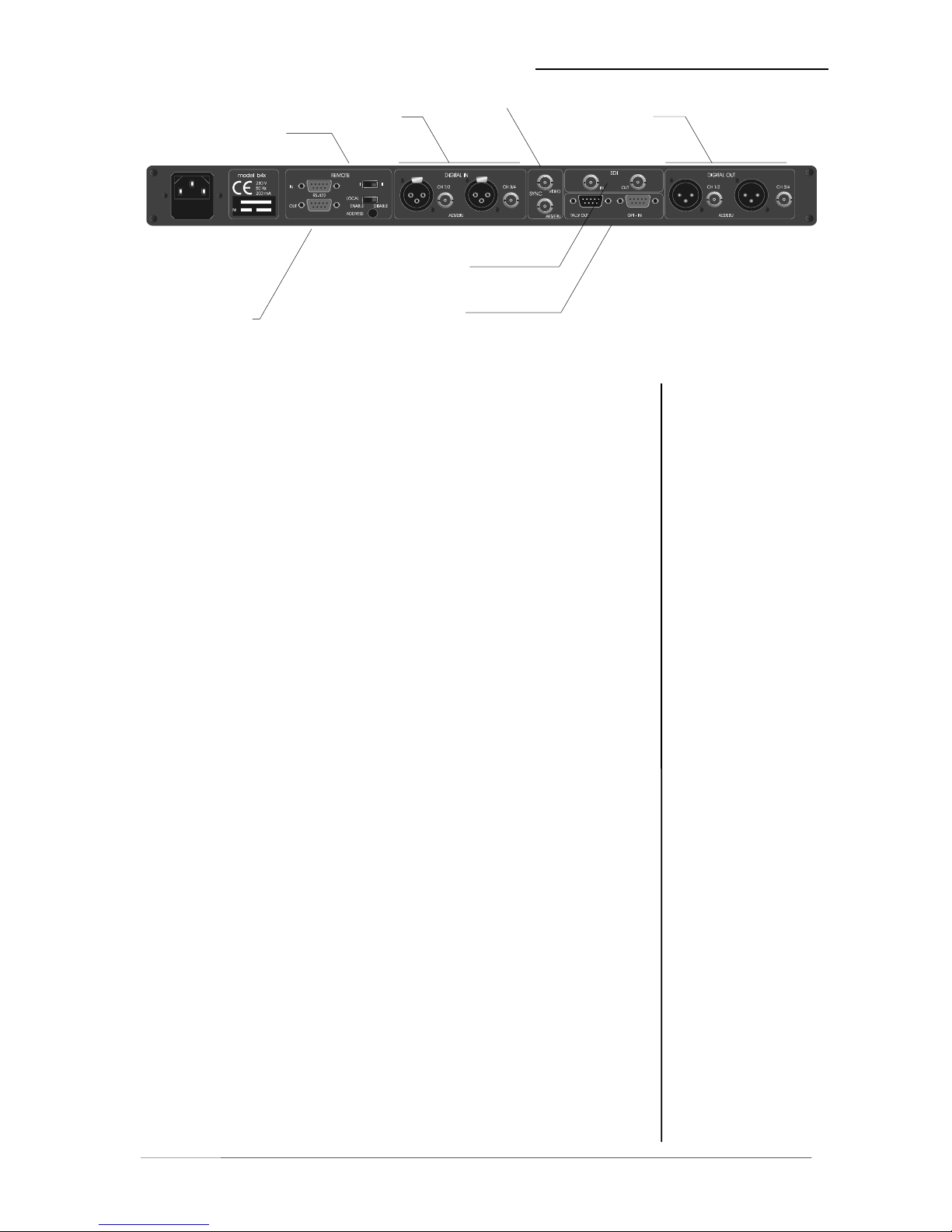

2. LOCATION OF PARTS AND CONTROLS

2.2.

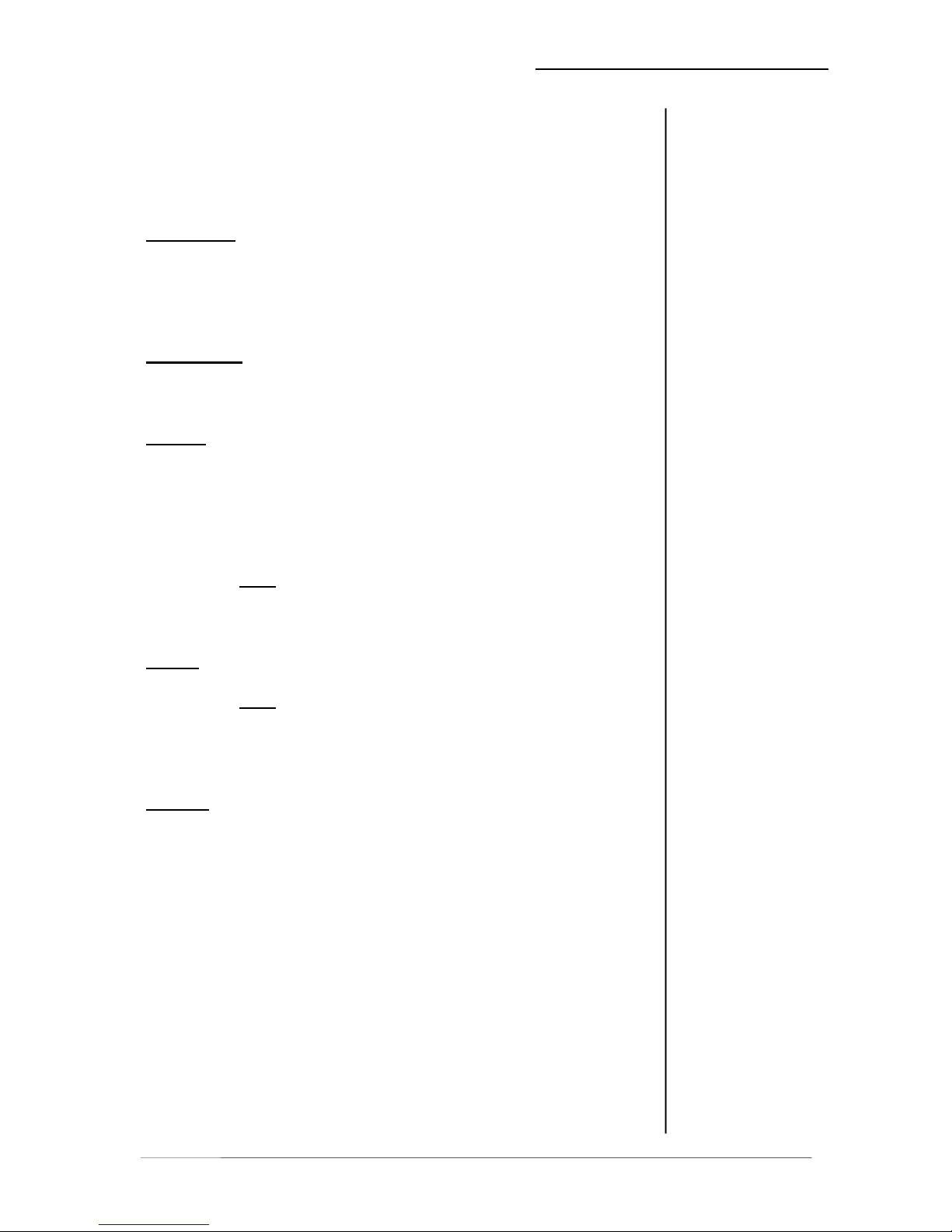

REAR PANEL

DIGITAL

OUTPUTS

DIGITAL

INPUTS

SYNC IN

BASIC

SETTINGS

SDI IN-/

OUTPUT

SERIAL

REMOTE

IN/OUT

GPI REMOTE

IN/OUT

fig. 2: rear panel b40

POWER INPUT

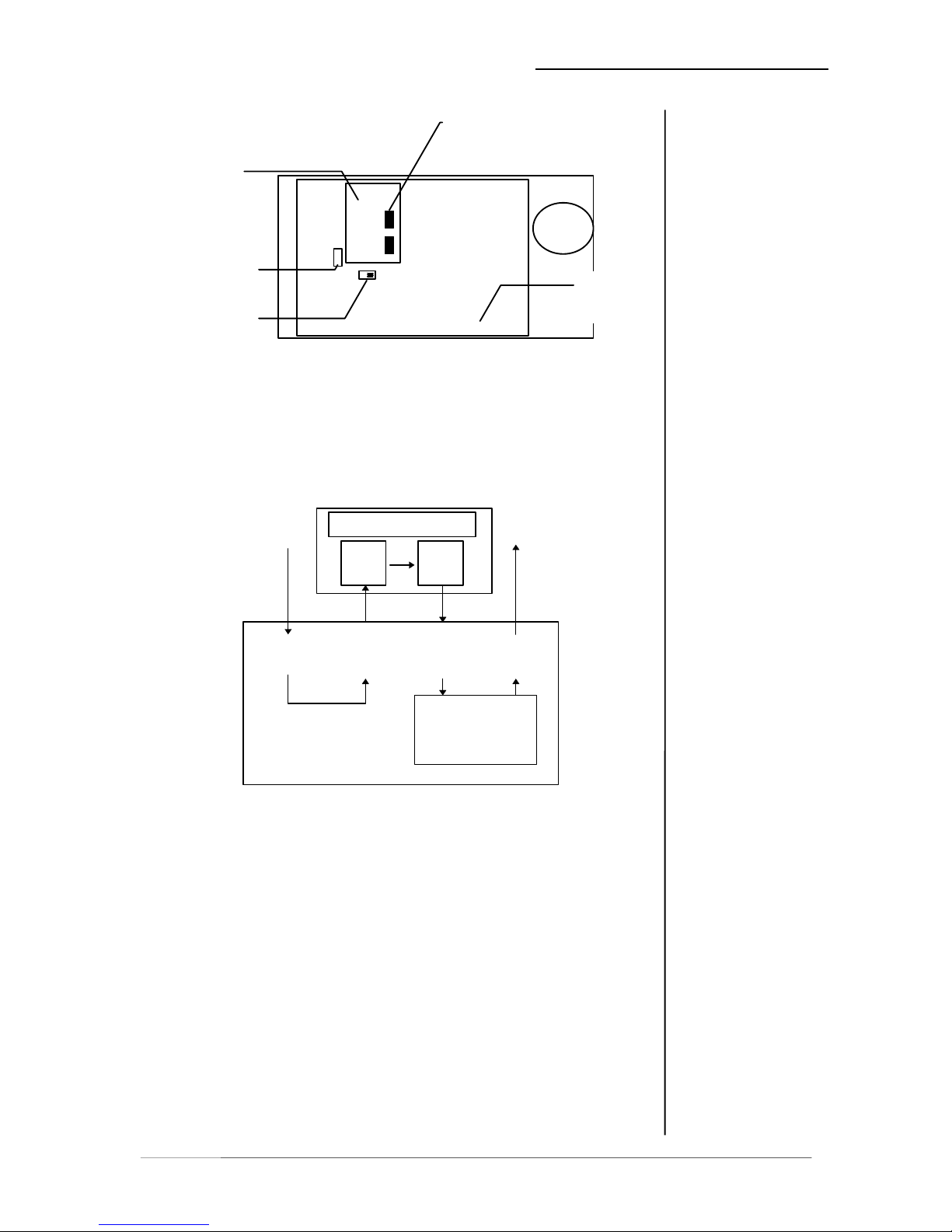

IEC mains input connector 230 V, 50 Hz (UK: 240 V, 50 Hz; JAPAN: 100 V,

60Hz; USA: 127 V, 60 Hz) with integrated fuse

REMOTE

serial remote interfacee RS-422

connector: 9pin SUB-D, input - male, output - female

GPI

paralle remote interface

TALLY-out TTL-level

connector: 9pin SUB-D, male

GPI-in TTL-level

connector: 9pin SUB-D, female

SYNC

AES/EBU input for ext. sync signal (AES 3 format, 75 Ohm, unbal)

connector: BNC socket

VIDEO input for video sync signal (blackburst, 75 Ohm, unbal)

connector: BNC socket

SDI IN / OUT (only for SDI-Version!)

Input/output for serial digital video (ITU-R BT.601, SMPTE 272M-A)

Format: • Video: 270 Mb/s, 525/625 line rate, 75 Ohm,

BNC socket

DIGITAL IN

input for AES/EBU standard format

connector: XLR female panel jack

1- ground, 2-3 signal, balanced

connector: BNC socket 75 Ohm, unbalanced

DIGITAL OUT

output for AES/EBU standard format

connector: XLR male panel jack

1- ground, 2-3 signal, balanced , 4 Vpp

connector: BNC socket 75 Ohm, unbalanced, 0.5V pp

hardware bypass: relais are connecting related inputs and outputs if power

is failed

Operation manual b40, chapter 2 -control elements and displays- page 2-3