T-27 Tucano 20cc 1.2 2022

www.juniaer.com.br

3

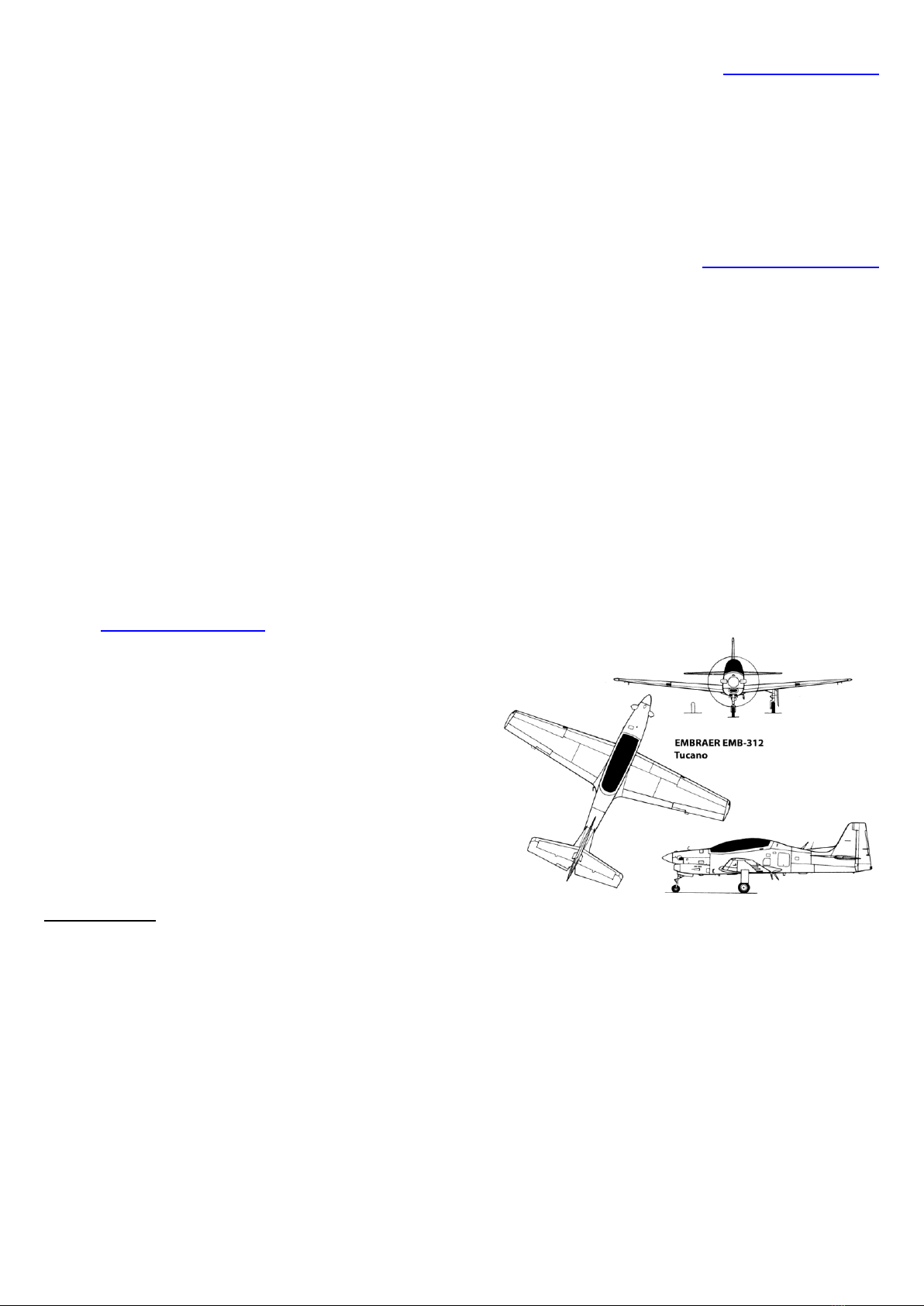

This is the T-27 Tucano 20cc ARF Juniaer, prepared for retracts installation, with flaps, with an exquisite

finishing and many painting schemes available, very realistic and all detailed in relief, with rivets, antennas, side

door with hinge and lock (not installed), panel lines, compartments, pitot tubes replicas, landing gear doors,

paneled cockpit and clear canopy. Engine cowling in 2 parts with exhaust replicas. Model airplane made of high-

quality epoxy resin with structural reinforcements, low weight and high resistance due to the FULL COMPOSITE

high technology vacuum lamination technique. 2-piece wing (1 aluminum tube on the wing) laminated in

fiberglass and epoxy resin with carbon fiber reinforcements and laser-cut plywood and balsa structures.

Laminated stabilizer in fiberglass and epoxy resin with carbon fiber reinforcements and structures in plywood

and balsa laser cut in a single piece to be permanently glued to the fuselage. Clear canopy, resin made canopy

frame and cockpit with instruments panels. Ailerons, flaps e and elevators factory hinged in perfect align.

Rudder to be epoxy glued in 3 hinge points provided with the kit. Servo tray and fuel tank tray made of laser cut

plywood. Exquisite automotive painting finishing, scale decals and markings and varnished for long lasting.

Stable, realistic and acrobatic flight pattern. Capable of many maneuvers such as slow rolls, rolls, Cuban eights,

knife edge flight, inverted flight and much more. This model airplane was developed and built to provide a high

performance both for pleasant flights as for wealth of details and realism. It´s construction and made with

specific high-quality materials and advanced composite lamination techniques to provide low weight and high

structural strength.

The Juniaer model airplanes are painted and varnished with high quality and resistance products. Even so,

some care must be taken to protect the paint: wipe your model with a cloth immediately after use with water

sprays and neutral detergent. Fuels can damage the varnish if it penetrates punctures or damages to the plane's

surface, as well as cuts in the engine's cowling. To prevent this kind of problem, we recommend brushing two-

component PU varnish or applying epoxy to areas that are uncovered for any reason. Avoid exposing the model

to direct sunlight as much as possible, especially the darker painted parts that accumulate and reflect a greater

amount of heat, causing an internal and external temperature raising. The use of automotive wax for polishing

is useful in preventing the accumulation of dirt and facilitates the cleaning and protection of the varnish. We

suggest the use of fabric smooth covers for storage and transport, in order to protect against damage and risks.

Be careful when handling your model airplane, especially the movable control surfaces. Never lift it by the two

wing tips only, as the total weight is considerable to be supported only by 2 distant points. When checking the

model airplane´s balance through the center of gravity (C.G.) always support it by the roots of the wing at the

indicated points.

Please read this manual to the end before doing anything on your model airplane, it contains important

information regarding assembly and use, and it will also give you an overview of what should be done correctly

and following the guidelines.

Please check and identify all parts of your model airplane when you receive it. If any parts are damaged or

defective, please contact our customer service. Your model aircraft has a 90-day factory warranty against

manufacturing defects. Juniaer Model Airplanes guarantees that this kit is free from manufacturing defects in

both material and workmanship at the date of purchase. This warranty does not cover any components

damaged by use or modifications. In no event will Juniaer's liability exceed the original cost of the kit purchased.

In addition, Juniaer Model Airplanes reserves the right to change this warranty without prior notice. Since

Juniaer Model Airplanes has no control over the final assembly or the equipment used for the final assembly,

no liability will be assumed or accepted for any damages resulting from the user's use of the final product

assembled by him or third parties. Through the act of using the assembled product by the user, he accepts all

responsibility for the result. If the buyer is not prepared to accept responsibility for the use of this product, it

must be returned immediately to the place of purchase in new and unused condition. This product is intended

for persons over 18 years old and any procedure involved in its assembly and use must be monitored by an

adult.