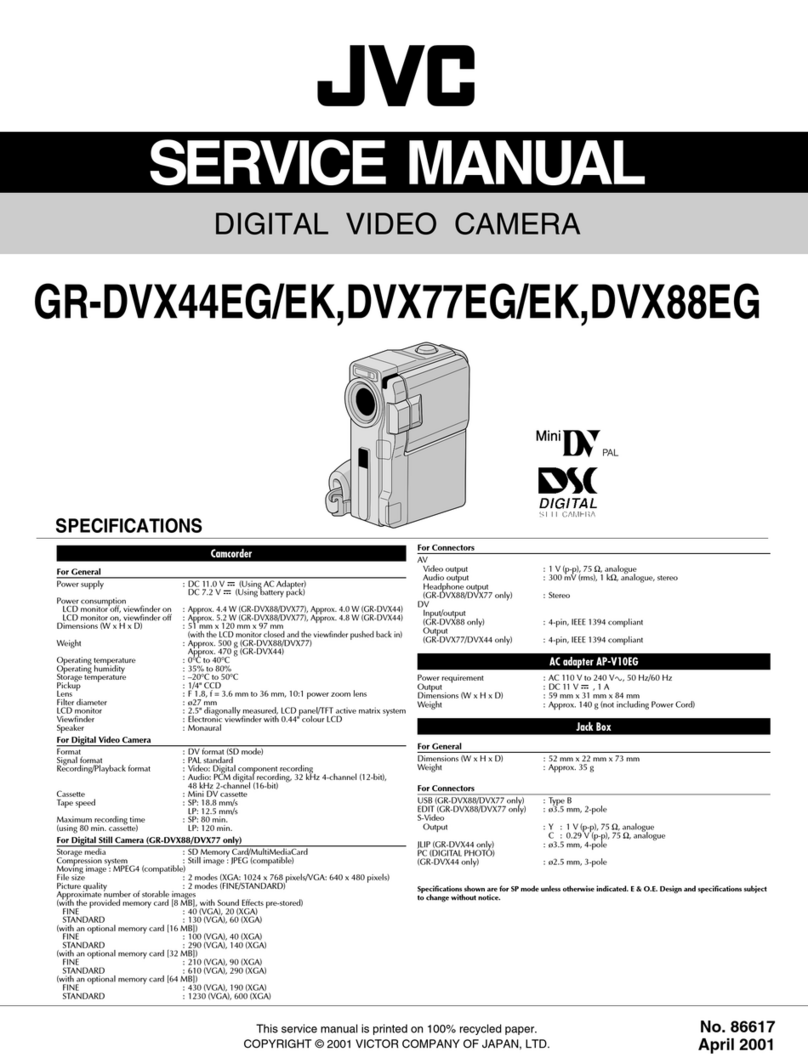

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .......................................... 4-1

CIRCUIT BOARD NOTES ........................................................... 4-2

4.1 BOARD INTERCONNECTIONS .......................................... 4-3

4.2 CPU SCHEMATIC DIAGRAM .............................................. 4-5

4.3 M. MDA SCHEMATIC DIAGRAM ......................................... 4-7

4.4 VTR ASP SCHEMATIC DIAGRAM ....................................... 4-9

4.5 DSP SCHEMATIC DIAGRAM............................................. 4-11

4.6 F/Z/I/MDA SCHEMATIC DIAGRAM .................................... 4-13

4.7 V OUT SCHEMATIC DIAGRAM ......................................... 4-15

4.8 TG/CDS SCHEMATIC DIAGRAM ...................................... 4-17

4.9 REG SCHEMATIC DIAGRAM ............................................ 4-19

4.10 LCD/CVF SCHEMATIC DIAGRAM [GR-AX970U] ........... 4-21

4.11 BW/CVF SCHEMATIC DIAGRAM [GR-AX770UC] .......... 4-23

4.12 BW/CVF SCHEMATIC DIAGRAM [GR-AX970U] ............ 4-25

4.13 JACK SCHEMATIC DIAGRAM ........................................ 4-27

4.14 CCD SCHEMATIC DIAGRAM .......................................... 4-29

4.15 C-VF BL SCHEMATIC DIAGRAM [GR-AX970U] ............. 4-30

4.16 C-VF SHEMATIC DIAGRAM [GR-AX970U] ..................... 4-31

4.17 E.VF SCHEMATIC DIAGRAM [GR-AX770UC] ................ 4-33

4.18 TOP OPE UNIT, ZOOM UNIT, REAR UNIT AND SENSOR

SCHEMATIC DIAGRAMS ................................................ 4-35

4.19 MAIN CIRCUIT BOARD ................................................... 4-37

4.20 CCD CIRCUIT BOARD .................................................... 4-43

4.21 E. VF CIRCUIT BOARD [GR-AX770UC] ......................... 4-44

4.22 C-VF CIRCUIT BOARD [GR-AX970U] ............................ 4-45

4.23 WAVEFORMS .................................................................. 4-46

4.24 VOLTAGE CHARTS ......................................................... 4-47

4.25 POWER SYSTEM BLOCK DIAGRAM ............................. 4-51

4.26 CAMERA AND Y/C SYSTEM BLOCK DIAGRAM ........... 4-53

4.27 CPU/MDA SYSTEM BLOCK DIAGRAM .......................... 4-57

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ................ 5-1

5.2 FINAL ASSEMBLY <M2> .................................................... 5-3

5.3 MECHANISM ASSEMBLY <M3> ....................................... 5-6

5.4

ELECTRONIC VIEWFINDER ASSEMBLY <M4> [GR-AX770UC] ...

5-8

5.4

ELECTRONIC VIEWFINDER ASSEMBLY <M4> [GR-AX970U] .....

5-9

5.5 ELECTRICAL PARTS LIST .................................................. 5-10

MAIN BOARD ASSEMBLY <01> ..................................................

5-10

CCD BOARD ASSEMBLY <02> ......................................... 5-16

C-VF BL BOARD ASSEMBLY <06>[AX970U] .................... 5-16

E.VF BOARD ASSEMBLY <60>[AX770UC] ....................... 5-16

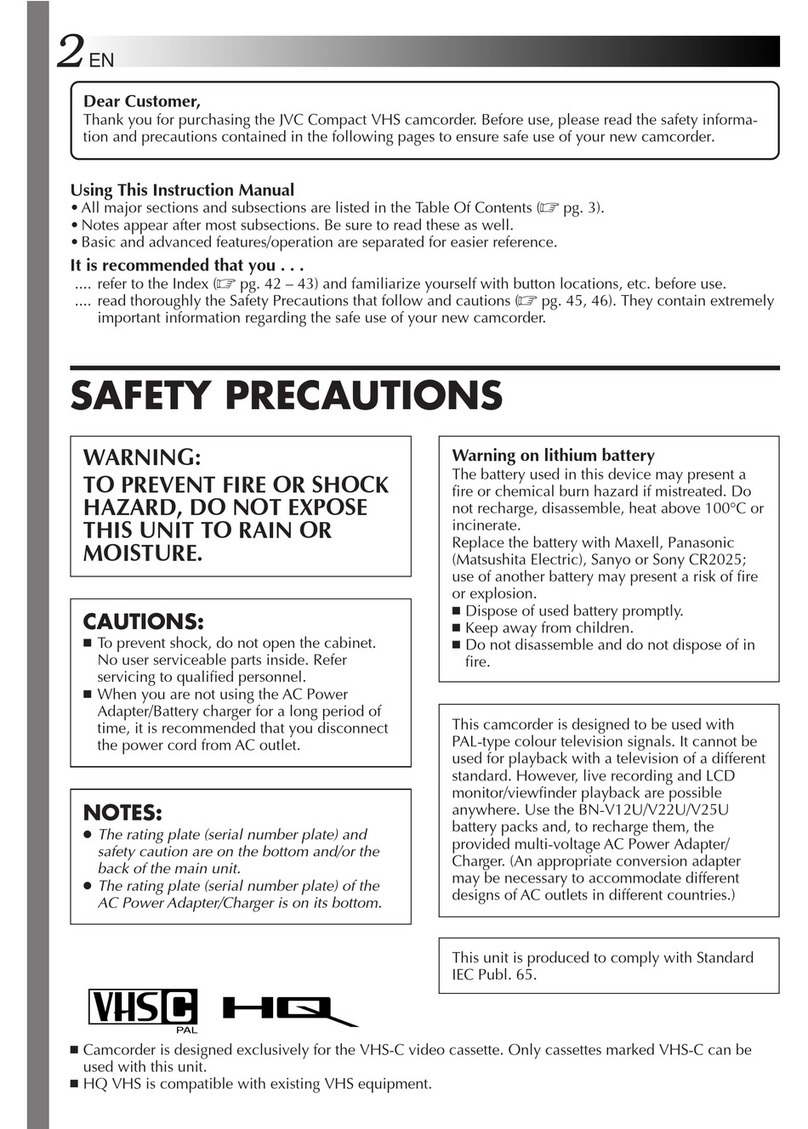

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 SERVICE CAUTIONS ............................................................ 1-1

1.1.1 Precautions ...................................................................... 1-1

1.1.2 How to read the disassembly and assembly ................... 1-1

1.1.3 Connection of the wires .................................................. 1-1

1.2 TOOLS REQUIRED FOR ADJUSTMENTS ........................... 1-2

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS ................ 1-3

1.3.1 Disassembly flow chart ................................................... 1-3

1.3.2 Disassembly method ....................................................... 1-4

1.4 DISASSEMBLY/ASSEMBLY OF CAMERA SECTION AND

DECK SECTION .................................................................... 1-8

1.4.1 Flowchart of disassembly ................................................ 1-8

1.4.2 Disassembly method ....................................................... 1-8

1.5 REPLACEMENT OF 3CCD IMAGE SENSOR ................... 1-10

1.5.1 Removal of CCD image sensor ..................................... 1-10

1.5.2 Installation of new CCD image sensor .......................... 1-10

1.5.3 Replacement of CCD board assembly .......................... 1-10

1.6 TAKE OUT CASSETTE TAPE .............................................. 1-11

1.7 EMERGENCY DISPLAY ...................................................... 1-12

1.8 DEMONSTRATION MODE ................................................. 1-12

1.9 SERVICE NOTE .................................................................. 1-14

2. MECHANISM ADJUSTMENT

2.1 SERVICE CAUTIONS ............................................................ 2-1

2.1.1 Precautions ...................................................................... 2-1

2.1.2 How to read the disassembly and assembly

(For Mechanism Parts) .................................................... 2-1

2.1.3 Required adjustment tools .............................................. 2-1

2.2 DISASSEMBLY/ASSEMBLY OF MECHANISM PARTS ........ 2-2

2.3 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE .. 2-6

2.4 TAPE TRANSPORT ADJUSTMENT ...................................... 2-7

2.4.1 Back tension .................................................................... 2-7

2.4.2 Tape pattern ..................................................................... 2-7

2.4.3 A/C head height & azimuth .............................................. 2-8

2.4.4 Phase of control head (X value) ....................................... 2-9

2.5 REMARKS ............................................................................ 2-9

2.5.1 Cleaning ........................................................................... 2-9

2.5.2 Applying oil and grease ................................................... 2-9

2.5.3 Checkup .......................................................................... 2-9

2.6 JIG CONNECTOR CABLE CONNECTION .......................... 2-10

3. ELECTRICAL ADJUSTMENT

3.1 ELECTRICAL ADJUSTMENT ................................................ 3-1

3.1.1 Preparation ...................................................................... 3-1

3.2 ELECTRONIC VIEWFINDER (E. VF) ADJUSTMENT

[B/W VF model only] ............................................................... 3-2

3.2.1 Tilt .................................................................................... 3-2

3.2.2 Centering ......................................................................... 3-2

3.2.3 Vertical scanning .............................................................. 3-2

3.2.4 Brightness ....................................................................... 3-2

3.2.5 Focus ............................................................................... 3-2

TABLE OF CONTENTS

Section Title Page Section Title Page

GR-AX770U GR-AX970U

E.VF B/W COLOR

DC LIGHT NOT USED USED

The following table lists the differing points between Models GR-AX770U and GR-AX970U in this serise.