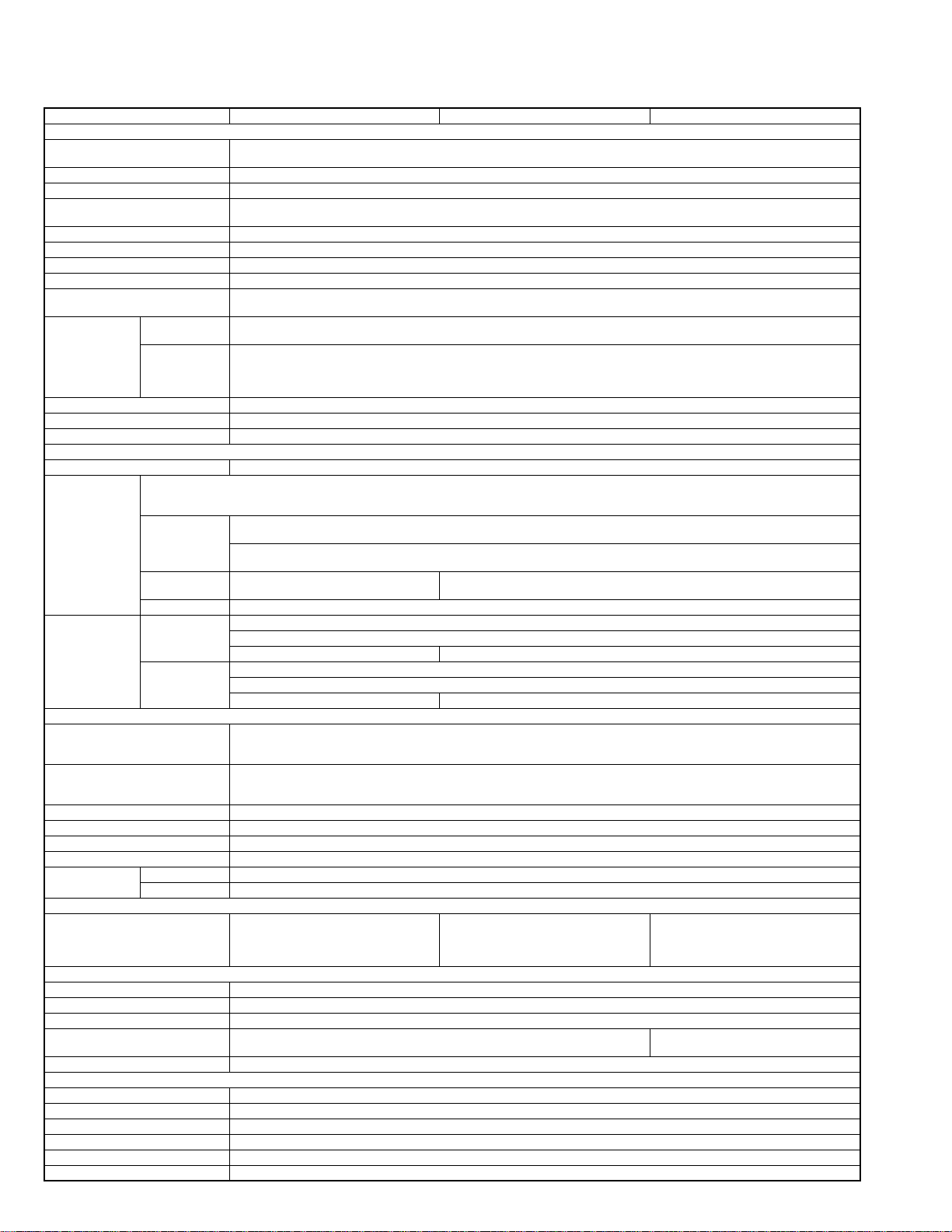

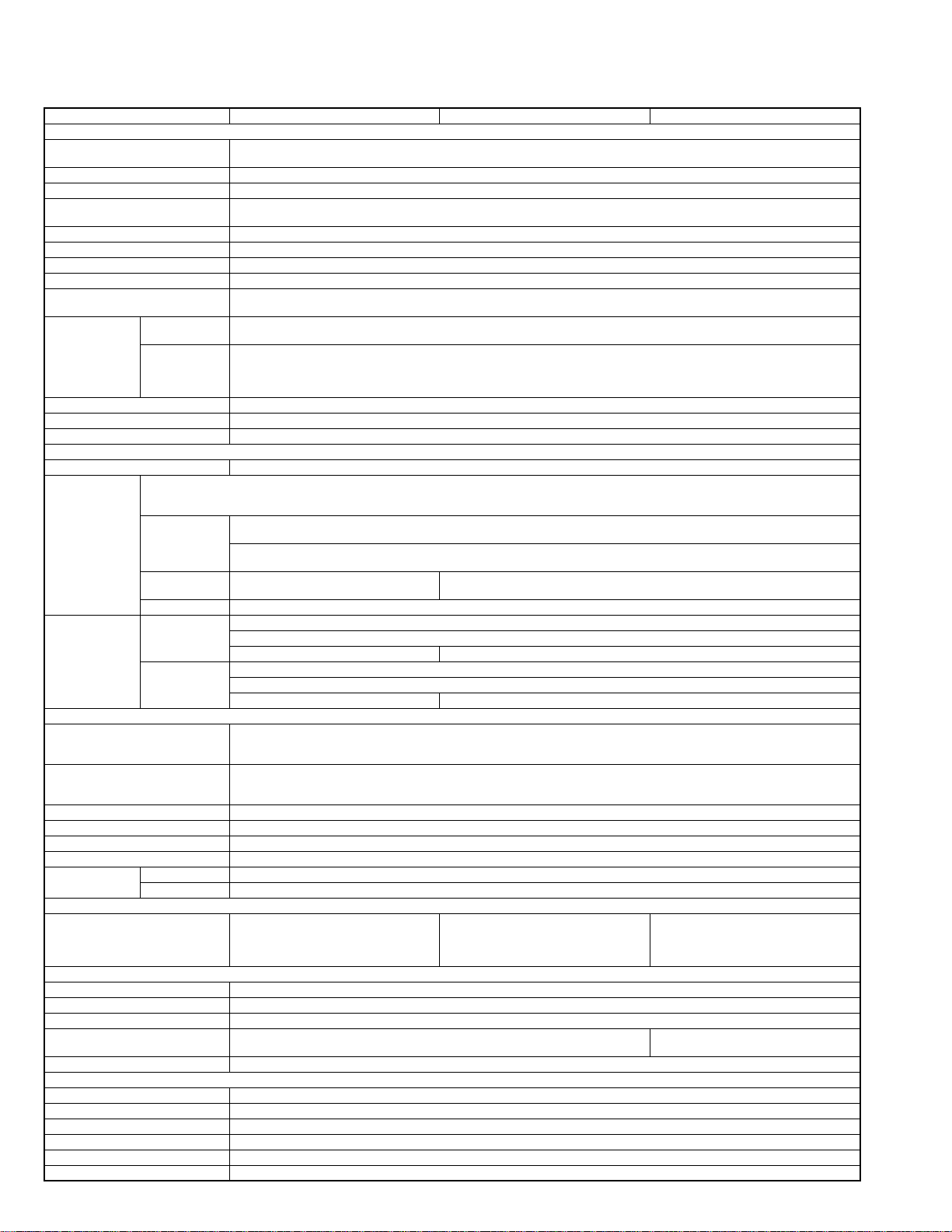

1-2 (No.HC044<Rev.001>)

SPECIFICATION

GY-HM150U GY-HM150E GY-HM150EC

General Power DC 11 V (using AC adapter)

DC 7.2 V (using battery)

Power consumption Approx. 8.3 W (when backlight is set to [STANDARD] while the LCD monitor or viewfinder is in use)

Dimensions 366 mm (W) ×179 mm (H) ×138 mm (D)(14-4/8" x 7-1/8" x 5-4/8")

Mass Approx. 1190 g (2.7 Ibs)

Approx. 1320 g (2.9 Ibs) (incl. battery BN-VF823U, SD card, micorophone)

Allowable operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Allowable operating humidity 35 % RH to 80 % RH

Allowable storage temperature -20 °C to 50 °C (-4 °F to 122 °F)

Image pickup device 1/4", Progressive CCD ×3

Lens F1.8 to 2.8

f = 3.7 mm to 37 mm

Filter diameter When the hood is

detached 46 mm (screw pitch: 0.75 mm)

Compatible with filter (external diameter: 50 mm and below),tele-converter, and wide-converter

When the hood is

attached 72 mm (screw pitch: 0.75 mm)

Compatible with filter (external diameter: 75 mm and below) only

* When removing the filter, do not press on the top and bottom of the hood. Doing so makes it difficult to remove the filter and may

damage the inner surface of the hood.

Zoom Up to 10x (optical zoom)

LCD screen 2.7", 16:9, 230,000 pixels

Viewfinder 0.24", 16:9, 260,000 pixels

Video/Audio Recording time Approx. 25 minutes (8 GB SDHC/SDXC card, 35 Mbps, VBR mode)

Video recording file

format QuickTime File Format(For Final Cut Pro)

MP4 File Format (HD only)

AVI File Format (SD only)

Video signal HD (HQ mode):MPEG-2 Long GOP

VBR, 35 Mbps (Max) MPEG-2

HD (SP mode):MPEG-2 Long GOP

CBR, 25 Mbps (1440x1080i) /19 Mbps(1280x720p) MPEG-2

SD DV

CBR, 25 Mbps (720x480i) DV

CBR, 25 Mbps (720x576i)

Audio signal LPCM 2ch, 48 kHz/16 Bit

Video format NTSC setting HD (HQ mode):1920x1080/59.94i, 29.97p, 23.98p, 1440x1080/59.94i, 1280x720/59.94p, 29.97p, 23.98p

HD (SP mode):1440x1080/59.94i, 1280x720/59.94p, 29.97p, 23.98p

SD:720x480/59.94i -

PAL setting HD (HQ mode):1920x1080/50i, 25p, 1440x1080/50i, 1280x720/50p, 25p

HD (SP mode):1440x1080/50i, 1280x720/50p, 25p

- SD:720x576/50i

Terminals AV terminal Video Analog output 1.0 V (p-p), 75 ΩAudio Analog output (stereo)

-8 dBu, 1 k Ω(when reference level -12 dB is selected)

-16 dBu, 1 k Ω(when reference level -20 dB is selected)

Component terminal Y, PB, PRcomponent output

Y: 1.0 V (p-p), 75 Ω

PB, PR: 700 mV (p-p), 75 Ω

HDMI terminal HDMITM Connector

USB terminal Mini USB-B type, USB 2.0

Headphone jack 3.5 mm mini jack (stereo)

Remote terminal 3.5 mm mini jack (4-pin)

Audio INPUT1/

INPUT2 terminals MIC -60 dBu, 3 kΩ, XLR (balanced), +48 V output (phantom power supply)

LINE +4 dBu, 10 k Ω, XLR (balanced)

Accessories AC adapter,Powercord×2,Battery,Battery

charger, Remote control unit, Audio unit,Mi-

crophone,AV cord,Component cable,CD-

ROM,Instruction manual,Warranty card

ACadapter, Power cord×4, Battery,Battery

charger,Remote controlunit, Audio unit,Mi-

crophone,AV cord,Component cable,CD-

ROM,Instruction manual

AC adapter, Power cord, Remote control

unit, Audio unit,Microphone,AV cord,Com-

ponent cable,CD-ROM,Instruction manu-

al,Warranty card

AC Adapter Power AC 100 V to 240 V, 50 Hz/60 Hz

Output DC 11 V =, 1 A

Allowable operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Dimensions 49 mm (W) ×26 mm (H) ×64 mm (D)(1-15/16" ×1-1/ 8" ×2-7/8")

(excluding cord and AC plug) 47 mm (W) ×28 mm (H) ×72 mm (D)

(excluding cord and AC plug)

Mass Approx. 86 g (0.19 Ibs)

Remote Control Unit Type DC 3 V (button battery CR2025)

Battery life Approx. 1 year (varies according to frequency of use)

Operating distance Approx. 5 m (16.4 ft) (along front axis)

Allowable operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Dimensions 42 mm (W) ×14.5 mm (H) ×91 mm (D)(1-6/8" ×9/16" ×3-5/ 8")

Mass Approx. 30 g (0.07 Ibs)(including button battery)