1-2 (No.MA069)

SPECIFICATION

Design and specifications are subject to change without notice.

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 45 W per channel

Rear 45 W per channel

Continuous Power Output (RMS) Front 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 17 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

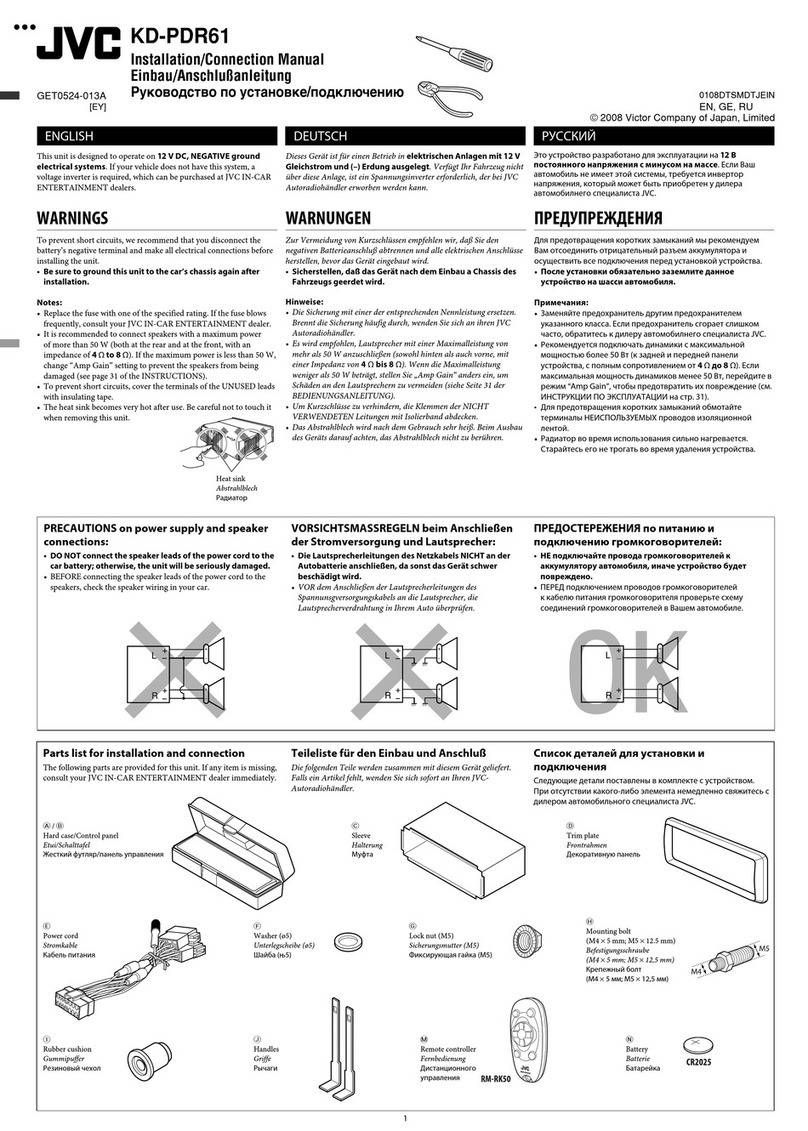

Load Impedance 4 Ω(4 Ωto 8 Ωallowance)

Tone Control Range Bass ±10 dB at 100 Hz

Treble ±10 dB at 10 kHz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩload (250 nWb/m)

TUNER SECTION

Frequency Range FM1/FM2 87.5 MHz to 108.0 MHz

FM3 65.00 MHz to 74.00 MHz

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

[MW Tuner] Sensitivity 20 µV

Selectivity 35 dB

[LW Tuner] Sensitivity 50 µV

CASSETTE DECK SECTION

Wow & Flutter 0.11% (WRMS)

Fast-Wind Time 100 sec. (C-60)

Frequency Response 30 Hz to 16 000 Hz (Normal tape)

Signal-to-Noise Ratio 56 dB

Stereo Separation 40 dB

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions (W ×H ×D) Installation Size (approx.) 182 mm ×52 mm ×150 mm

Panel Size (approx.) 188 mm ×58 mm ×12 mm

Mass (approx.) 1.5 kg (excluding accessories)