(No.YD052)1-3

SECTION1

PRECAUTION

1.1SAFTYPRECAUTIONS

Priortoshipmentfromthefactory,JVCproductsarestrictlyin-

spectedtoconformwiththerecognized productsafetyandelec-

tricalcodesofthecountriesinwhichtheyaretobe

sold.However,inorder tomaintainsuchcompliance, it isequally

importanttoimplementthefollowingprecautionswhen asetis

beingserviced.

1.1.1PrecautionsduringServicing

(1)Locationsrequiringspecialcautionaredenoted bylabels

andinscriptionsonthecabinet,chassisandcertainpartsof

theproduct.When performingservice,besuretoread and

complywiththeseandothercautionarynoticesappearing

intheoperationand servicemanuals.

(2)Partsidentified bythesymbolandshaded() parts

arecritical forsafety.

Replaceonlywithspecifiedpart numbers.

NOTE:

Partsinthiscategoryalsoincludethose specifiedto

complywithX-rayemission standards forproducts

usingcathoderaytubesandthose specifiedfor

compliancewithvariousregulationsregardingspu-

riousradiationemission.

(3)Fuse replacement caution notice.

Cautionfor continuedprotectionagainst firehazard.

Replaceonlywithsametypeand ratedfuse(s)as speci-

fied.

(4)Usespecified internal wiring. Noteespecially:

WirescoveredwithPVCtubing

Doubleinsulated wires

Highvoltageleads

(5)Usespecifiedinsulating materialsforhazardous liveparts.

Noteespecially:

InsulationTape

PVCtubing

Spacers

Insulationsheetsfor transistors

Barrier

(6)Whenreplacing AC primarysidecomponents(transformers,

powercords,noiseblockingcapacitors,etc.) wrap endsof

wires securelyabout the terminalsbeforesoldering.

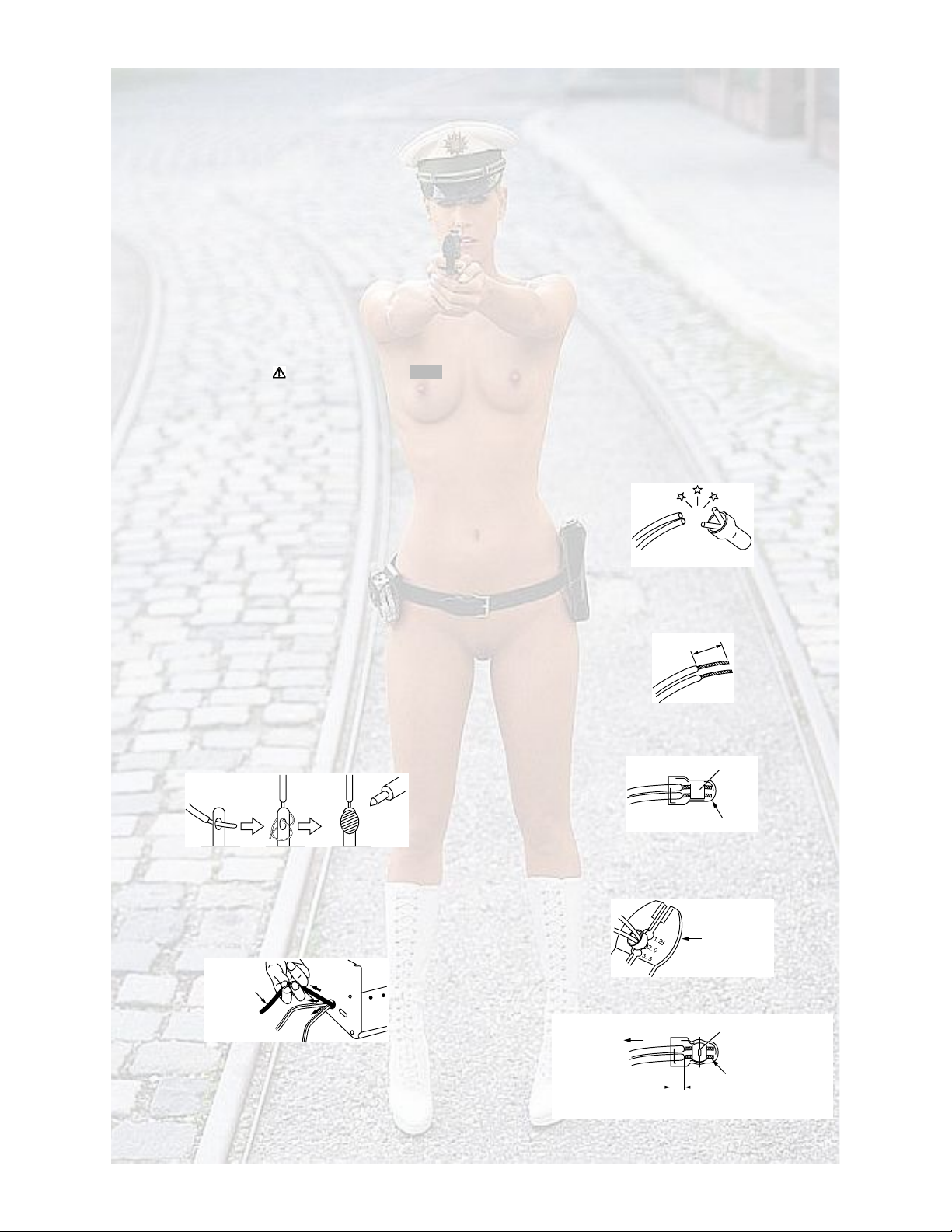

Fig.1-1-1

(7)Observe thatwiresdo notcontactheatproducing parts

(heatsinks,oxide metalfilmresistors,fusibleresistors,etc.)

(8)Checkthatreplaced wiresdo notcontactsharpedgedor

pointed parts.

(9)Whenapowercordhas beenreplaced,checkthat10-15

kgofforceinanydirectionwill not loosenit.

Fig.1-1-2

(10)Alsocheckareassurroundingrepairedlocations.

(11)Productsusingcathoderaytubes(CRTs)Inregardtosuch

products, thecathoderaytubesthemselves, thehighvolt-

agecircuits,and relatedcircuitsarespecifiedforcompli-

ancewithrecognizedcodespertainingtoX-rayemission.

Consequently, whenservicingtheseproducts,replacethe

cathoderaytubesand otherpartswithonlythespecified

parts.Undernocircumstancesattempt tomodifythesecir-

cuits.Unauthorizedmodificationcanincreasethe highvolt-

agevalueand causeX-ray emissionfromthecathoderay

tube.

(12)Crimptype wireconnectorInsuchcases aswhen replacing

thepowertransformerinsetswheretheconnectionsbe-

tweenthepowercordandpowertrans formerprimarylead

wiresareperformedusingcrimptypeconnectors, if replac-

ingthe connectorsisunavoidable,inordertopreventsafe-

tyhazards,performcarefullyandpreciselyaccordingtothe

followingsteps.

Connectorpart number :E03830-001

Requiredtool :Connectorcrimpingtooloftheproper

typewhichwill not damageinsulatedparts.

Replacementprocedure

a)Remove the oldconnectorbycuttingthewiresat a

pointclose totheconnector.Important:Donotre-

useaconnector (discardit).

Fig.1-1-3

b)Stripabout15mmoftheinsulationfromtheends

ofthe wires.Ifthewiresarestranded,twistthe

strands toavoidfrayed conductors.

Fig.1-1-4

c)Alignthelengthsofthewirestobeconnected.In-

sert the wiresfullyintothe connector.

Fig.1-1-5

d)AsshowninFig.1-1-6,usethecrimping tooltocrimp

themetalsleeveatthecenterposition.Besureto

crimpfullytothe completeclosureof the tool.

Fig.1-1-6

e)CheckthefourpointsnotedinFig.1-1-7.

Fig.1-1-7

б©»®½±®¼

½«¬ ½´±-»¬±½±²²»½¬±®

ïë ³³

ݱ²²»½¬±®

Ó»¬¿´-´»»ª»

Ý®·³°·²¹ ¬±±´

Ò±¬ »¿-·´§°«´´»¼º®»» Ý®·³°»¼¿¬¿°°®±¨ò½»²¬»

±º ³»¬¿´-´»»ª»

ݱ²¼«½¬±®-»¨¬»²¼»¼

É·®»·²-«´¿¬·±²®»½»--»¼

³±®»¬¸¿²ì³³