TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 Manually removing the cassette tape ......................... 1-1

1.2 Removing the major parts ........................................... 1-2

1.2.1 How to read the procedure table........................... 1-2

1.2.2 Disassembly procedure ........................................ 1-2

1.3 Emergency display function ........................................ 1-4

1.3.1 Displaying the EMG information ........................... 1-4

1.3.2 Clearing the EMG history ...................................... 1-4

1.3.3

Details of the OSD display in the EMG display mode

... 1-5

1.3.4 EMG content description....................................... 1-6

1.3.5 EMG detail information<1> ................................... 1-7

1.3.6 EMG detail information<2> ................................... 1-8

1.3.7 EMG detail information<3> ................................... 1-8

1.4 Service position........................................................... 1-9

1.4.1 How to set the "Service position" .......................... 1-9

1.5 Jig RCU mode............................................................. 1-9

1.5.1 Setting the Jig RCU mode .................................... 1-9

1.5.2 Setting the User RCU mode ................................. 1-9

1.6 Mechanism service mode ........................................... 1-9

1.6.1 How to set the "Mechanism service mode"........... 1-9

1.6.2 How to exit from the "Mechanism service mode".. 1-9

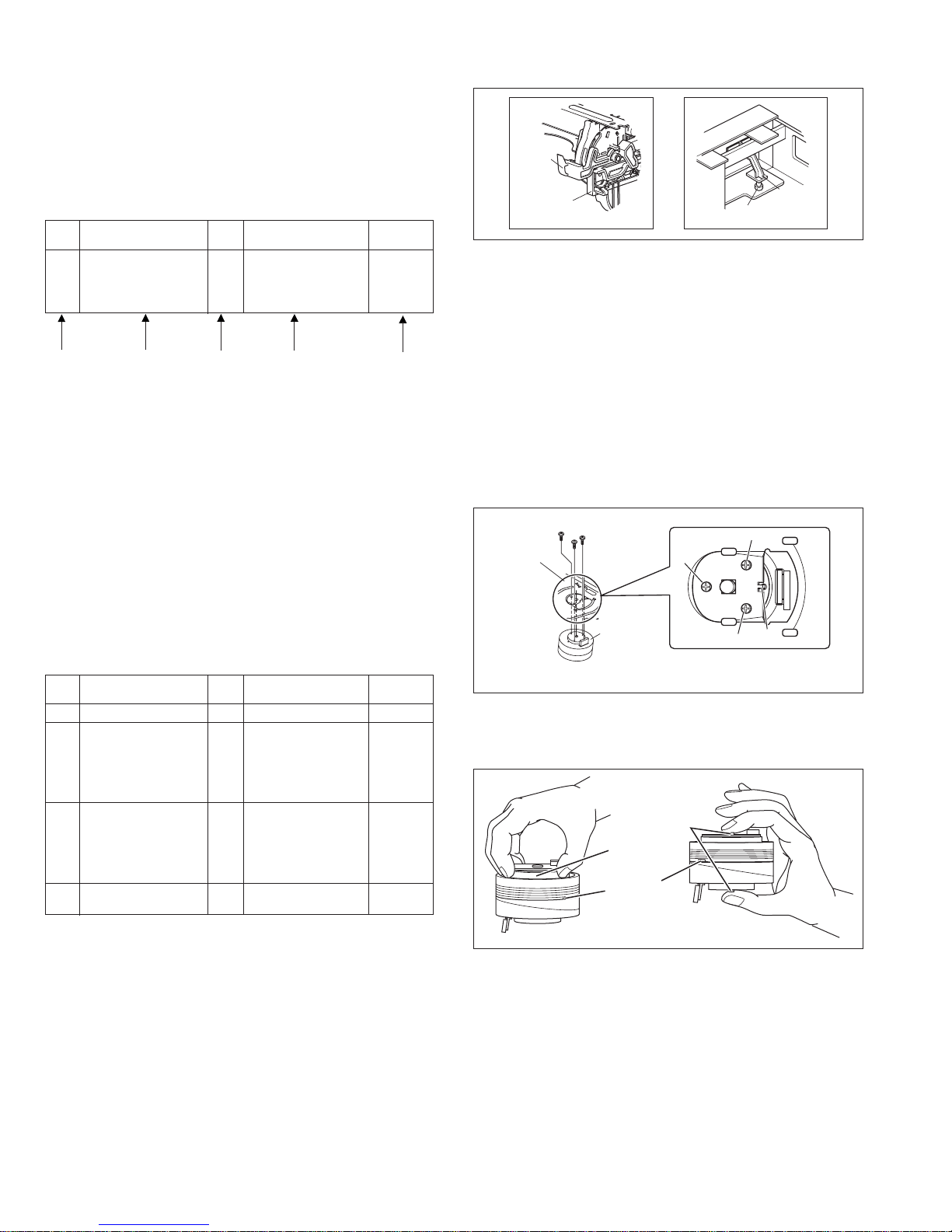

1.7 Maintenance and inspection ..................................... 1-10

1.7.1 Cleaning .............................................................. 1-10

1.7.2 Lubrication .......................................................... 1-10

1.7.3

Suggested servicing schedule for main components

.. 1-10

2. MECHANISM

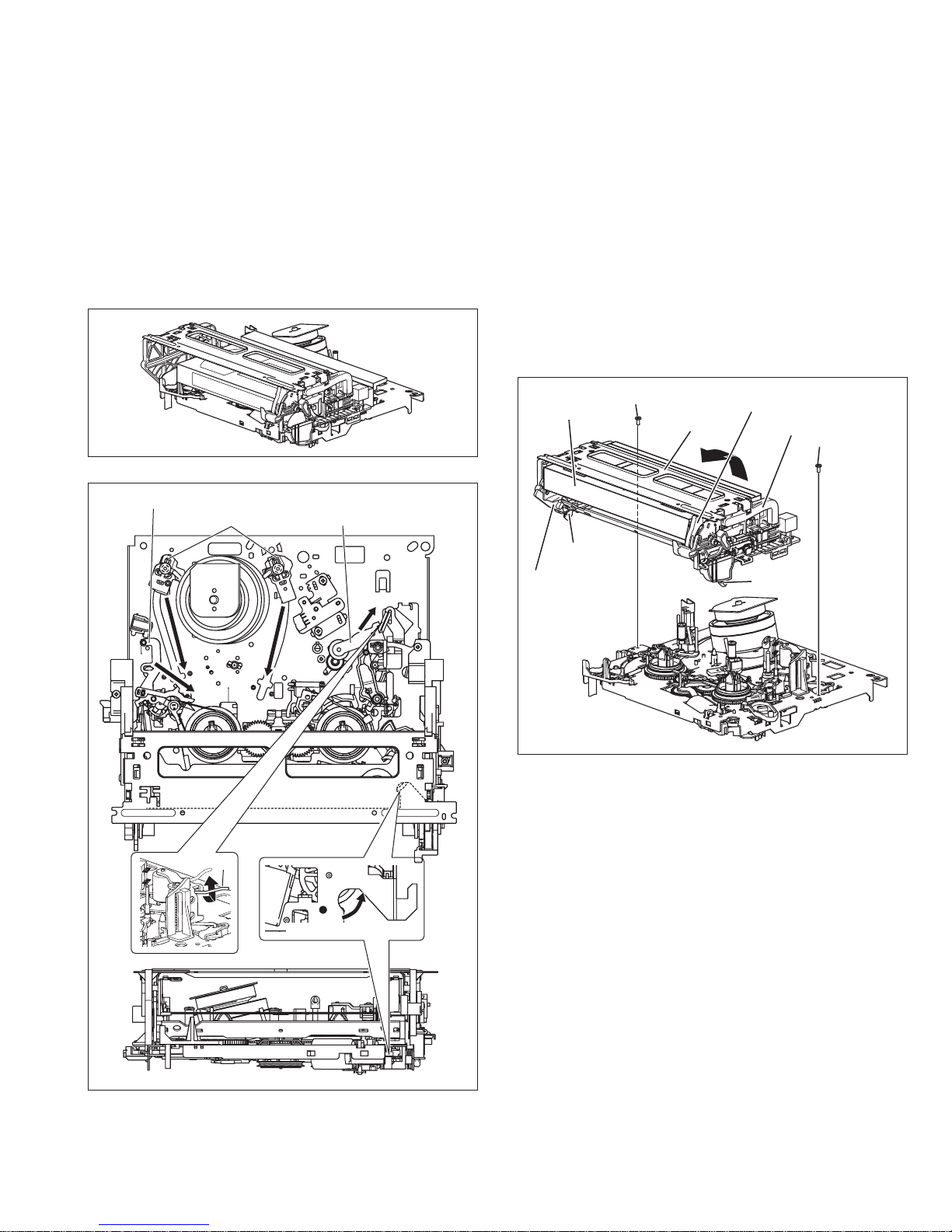

2.1 Before disassembling.................................................. 2-1

2.1.1 Notes..................................................................... 2-1

2.1.2 Mechanism operation check ................................. 2-1

2.1.3 Setting the mechanism assembling mode ............ 2-1

2.1.4 Layout of the main mechanism parts .................... 2-2

2.1.5 Disassembling procedure table............................. 2-3

2.2 Replacement of the main mechanism parts................ 2-4

2.2.1 Cassette holder ..................................................... 2-4

2.2.2 A/C head ............................................................... 2-5

2.2.3 Guide arm, pinch roller arm .................................. 2-6

2.2.4 Idler arm, idler gear 1/2 ......................................... 2-6

2.2.5

Main brake(T), brake lever, tension arm,reel disk(S/T), Rec safety lever

... 2-6

2.2.6

Press lever, control cam, capstan brake assembly,loading motor assembly

. 2-7

2.2.7 Capstan motor, load gear, control plate ................ 2-8

2.2.8 Clutch unit assembly, direct gear .......................... 2-9

2.3 Mechanism timing chart ............................................ 2-10

3. ADJUSTMENT

3.1 Before adjustment ........................................................3-1

3.1.1 Precaution ............................................................. 3-1

3.1.2 Required test equipments ..................................... 3-1

3.1.3 Required adjustment tools .................................... 3-1

3.1.4 Color(colour) bar signal, color(colour) bar pattern 3-1

3.1.5 Switch settings ...................................................... 3-1

3.1.6

Manual tracking mode (Auto tracking ON/OFF) setting

3-2

3.1.7 EVR adjustment .................................................... 3-2

3.2 Mechanism compatibility adjustment .......................... 3-2

3.2.1 Tension pole position............................................. 3-2

3.2.2 FM waveform linearity ........................................... 3-3

3.2.3 Height and tilt of the A/C head .............................. 3-3

3.2.4 A/C head phase(X-value) ...................................... 3-4

3.3 Electrical adjustment ................................................... 3-4

3.3.1 Servo circuit .......................................................... 3-4

3.3.1.1 Switching point ................................................. 3-4

3.3.1.2 Slow tracking preset......................................... 3-4

3.3.2 Video circuit........................................................... 3-5

3.3.2.1 EE Y/PB Y (S-VHS/VHS)level.......................... 3-5

3.3.3 Audio circuit........................................................... 3-5

3.3.3.1 Audio REC FM ................................................. 3-5

The following table lists the differing point(s) between models HR-S5901U, HR-S5911U, and HR-S5911U(C).

MODEL HR-S5901U

ITEM

BODY COLOR BLACK PURE-SILVER

4. CHARTS AND DIAGRAMS

4.1 BOARD INTERCONNECTIONS ................................. 4-3

4.2 MAIN(VIDEO/N. AUDIO) SCHEMATIC DIAGRAM ..... 4-5

4.3 MAIN(S-SUB) SCHEMATIC DIAGRAM ...................... 4-7

4.4 MAIN(SYSCON) SCHEMATIC DIAGRAM.................. 4-9

4.5 MAIN(SW.REG) SCHEMATIC DIAGRAM................. 4-11

4.6 MAIN(TUNER) SCHEMATIC DIAGRAM................... 4-13

4.7 MAIN(FMA/DEMOD) SCHEMATIC DIAGRAM ......... 4-15

4.8 MAIN(FRONT) SCHEMATIC DIAGRAM................... 4-17

4.9 MAIN(TERMINAL) SCHEMATIC DIAGRAM............. 4-19

4.10 2D DIGITAL SCHEMATIC DIAGRAM ..................... 4-21

4.11 2D DIGITAL CIRCUIT BOARD ................................ 4-23

4.12 MAIN CIRCUIT BOARD.......................................... 4-25

4.13 REMOTE CONTROLLER SCEMATIC DIAGRAM .. 4-27

4.14 WAVEFORMS ......................................................... 4-28

4.15 VOLTAGE CHARTS ................................................ 4-29

4.16

FDP GRIDASSIGNMENTANDANODE CONNECTION

...4-29

4.17 CPU PIN FUNCTION .............................................. 4-30

4.18 SYSTEM CONTROL BLOCK DIAGRAM................ 4-31

4.19 VIDEO BLOCK DIAGRAM ...................................... 4-33

4.20 AUDIO BLOCK DIAGRAM ...................................... 4-37

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY<M1> ....... 5-1

5.2 FINALASSEMBLY<M2> ............................................. 5-2

5.3 MECHANISM ASSEMBLY<M4> ................................. 5-4

5.4 ELECTRICAL PARTS LIST ......................................... 5-6

MAIN BOARD ASSEMBLY<03> ..................................... 5-6

2D DIGITAL BOARD ASSEMBLY<05> ......................... 5-12

A/C HEAD BOARDASSEMBLY<12> ........................... 5-13

REAR S JACK BOARD ASSEMBLY<29>..................... 5-13

FRONT S JACK BOARDASSEMBLY<36> .................. 5-13

ADV.JOG/SW BOARD ASSEMBLY<38> ...................... 5-13

LOADING MOTOR BOARDASSEMBLY<55>.............. 5-13

R.PAUSE BOARD ASSEMBLY<99>............................. 5-13

HR-S5911U HR-S5911U(C)

Note(s): Mark is same as left.