5 Conguraon and calibraon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Conguring the refractometer ............................. 24

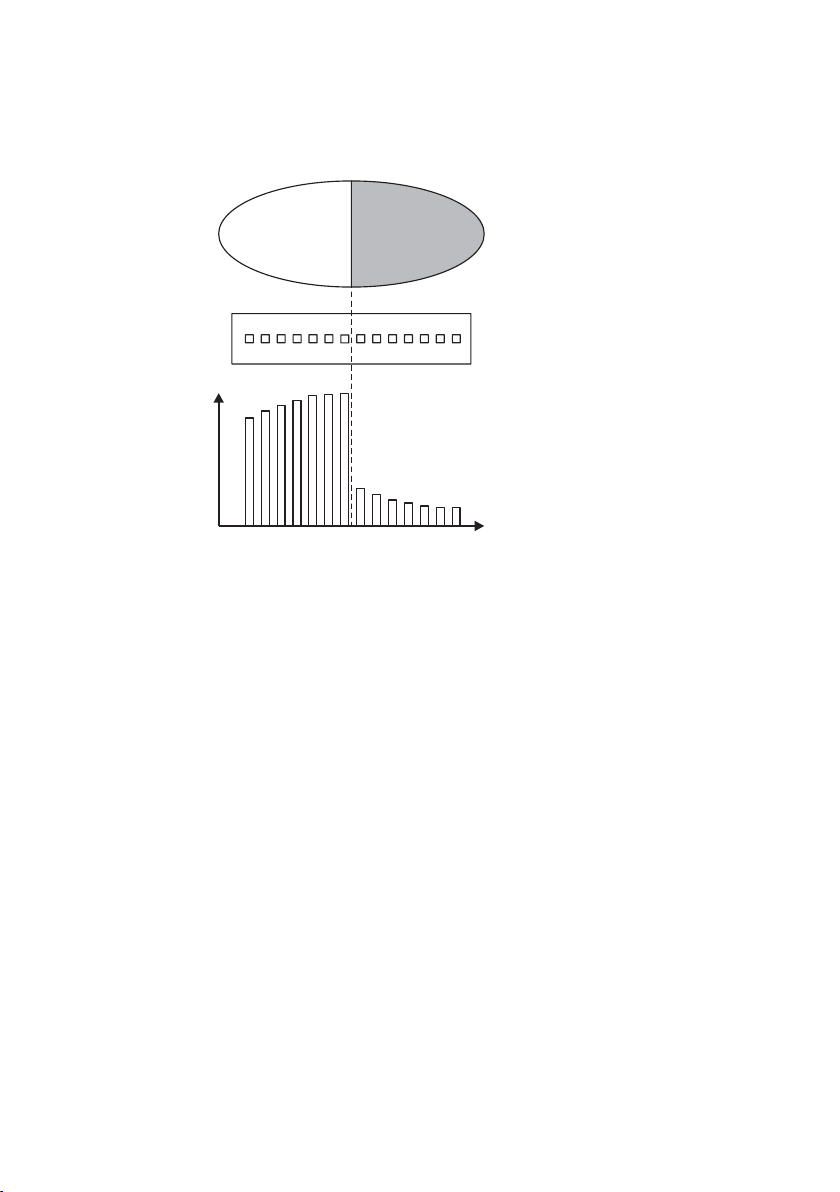

5.1.1 Signaldamping ....................................... 24

5.2 Calibrang the concentraon measurement .................. 26

5.2.1 Thechemicalcurve .................................... 27

5.2.2 DirectBIASadjustment ................................. 28

6 Regularmaintenance ........................................... 29

6.1 Prevenve replacement of o-ring in EKC265 applicaon ........ 29

7 Troubleshoong ............................................... 30

7.1 Hardware .............................................. 30

7.1.1 Message HIGH SENSOR HUMIDITY ............................ 30

7.1.2 Message HIGH SENSOR TEMP ............................... 30

7.2 Measurement .......................................... 30

7.2.1 Message OUTSIDE LIGHT ERROR or OUTSIDE LIGHT TO PRISM .......... 30

7.2.2 Message NO OPTICAL IMAGE ............................... 30

7.2.3 Message PRISM COATED .................................. 31

7.2.4 Message LOW IMAGE QUALITY .............................. 31

7.2.5 Message NO SAMPLE .................................... 31

7.2.6 Message TEMP MEASUREMENT FAULT ......................... 31

7.2.7 Concentraon dri during NORMAL OPERATION ................ 32

7.3 Diagnosc messages table ................................ 32

8 Ethernet protocol specicaon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1 Communicaon protocol ................................. 33

8.1.1 Requestformat ....................................... 33

8.1.2 Responseformat ...................................... 34

8.1.3 Request and response errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Request-response pair specicaon ........................ 35

8.2.1 NULLmessage ........................................ 35

8.2.2 Protocolversion ....................................... 35

8.2.3 Refractometer informaon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2.4 Measurementresults .................................. 36

8.3 Error message specicaon ............................... 37

Index ............................................................ 39