AT100-0200-1 Rev L (10-2010) DCN0528 2

TABLE OF CONTENTS

1.0 INTRODUCTION ............................................................................................................................................... 4

2.0 STORAGE INFORMATION .............................................................................................................................. 5

3.0 INSTALLATION AND BASIC WIRING............................................................................................................. 5

3.1 All Installations ............................................................................................................................... 5

3.1.1 Compression Fittings ............................................................................................................ 5

3.1.2 Floats .................................................................................................................................... 5

3.1.3 Transmitter Housing Height .................................................................................................. 5

3.2 Stilling Probes ................................................................................................................................ 5

3.2.1 Assembly Instructions for F1 Flexible Probes ....................................................................... 6

3.3 Loop Wiring.................................................................................................................................... 6

3.4 Jumper Settings ............................................................................................................................. 6

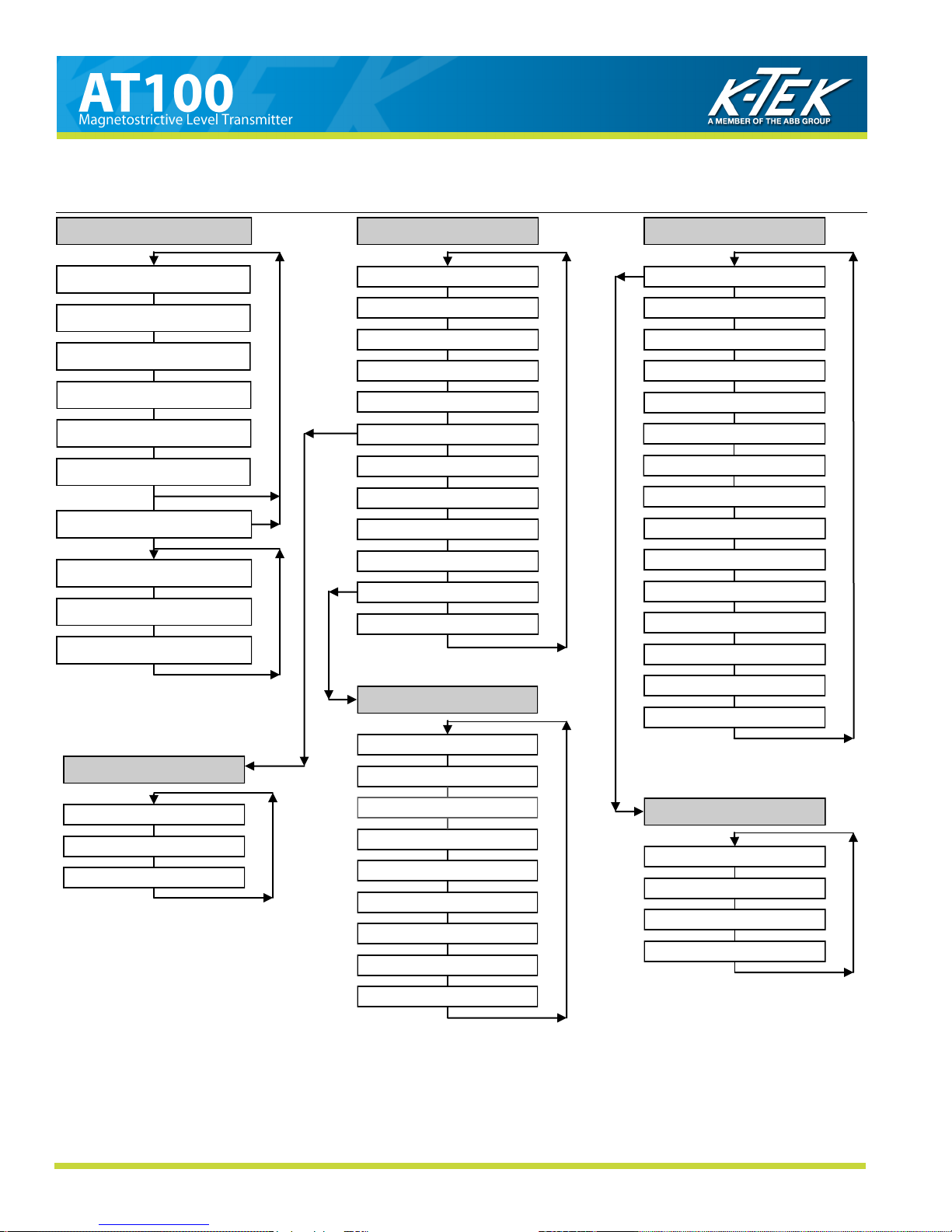

4.0 TRANSMITTER CALIBRATION AND SETUP ................................................................................................. 7

4.1 Level Output Calibration ................................................................................................................ 7

4.1.1 Calibration Using the Pushbuttons........................................................................................7

4.2 Reversing Action ............................................................................................................................ 7

4.2.1 Reverse Action Calibration Using the Pushbuttons ..............................................................7

4.3 Damping......................................................................................................................................... 7

4.4 Calibration Using the LCD Setup Menu......................................................................................... 9

4.5 Selecting a Primary Variable (PV) ................................................................................................. 9

4.6 Selecting an Engineering Unit for Measurement (EUN) .............................................................. 10

4.7 Level Offsets (L1O and L2O) ....................................................................................................... 10

4.8 DAC Trim ..................................................................................................................................... 10

4.9 Temperature Output..................................................................................................................... 10

4.9.1 Selecting the Unit of Temperature (EUN TEMP) ................................................................10

4.9.2 Temperature Output Calibration.......................................................................................... 11

4.9.3 Temperature Reset (TMP RSET)........................................................................................ 11

4.9.4 Temperature Master Calibration ......................................................................................... 11

4.10 Volumetric Strapping.................................................................................................................. 12

4.10.1 How the Strapping Table Works ....................................................................................... 12

4.10.2 Setting Up (or resetting) the Strapping Table.................................................................... 12

4.10.3 Selecting the Input Mode (Automatic or Manual) ..............................................................12

4.10.4 Setting Up Strapping Table Points .................................................................................... 13

4.10.5 Notes on Strapping Table Usage ...................................................................................... 13

4.10.6 Saving/Loading a Strapping Table ....................................................................................13

4.10.7 Setting Current Output Based on Volume......................................................................... 13

4.11 Alarm Delay ........................................................................................................................................14

4.12 Custom Current Ranging ............................................................................................................ 14

4.12.1 Description and Method of Operation ................................................................................14

4.12.2 CCR Set Up .......................................................................................................................14

5.0 COMMUNICATION OPTIONS........................................................................................................................ 15

5.1 Hart Protocol Interface Option ..................................................................................................... 15

5.1.1 Using a 268/275/375 Rosemount Communicator or Equal................................................. 15

5.2 Honeywell DE Protocol ................................................................................................................ 15

5.2.1 Interoperability and Conformance Class .............................................................................15

5.2.2 Operating Modes................................................................................................................. 15

5.3 Foundation Fieldbus .................................................................................................................... 16

5.3.1 Topology ............................................................................................................................. 16

5.3.2 Electrical Considerations..................................................................................................... 16

5.3.3 Field Wiring ......................................................................................................................... 17

5.3.4 Jumper Settings ..................................................................................................................17

5.3.5 DD Files .............................................................................................................................. 17

5.3.6 Transducer Block ................................................................................................................ 17

5.3.7 Al Function Blocks............................................................................................................... 17