2 For Professional Technical Support call 1-844-242-2475

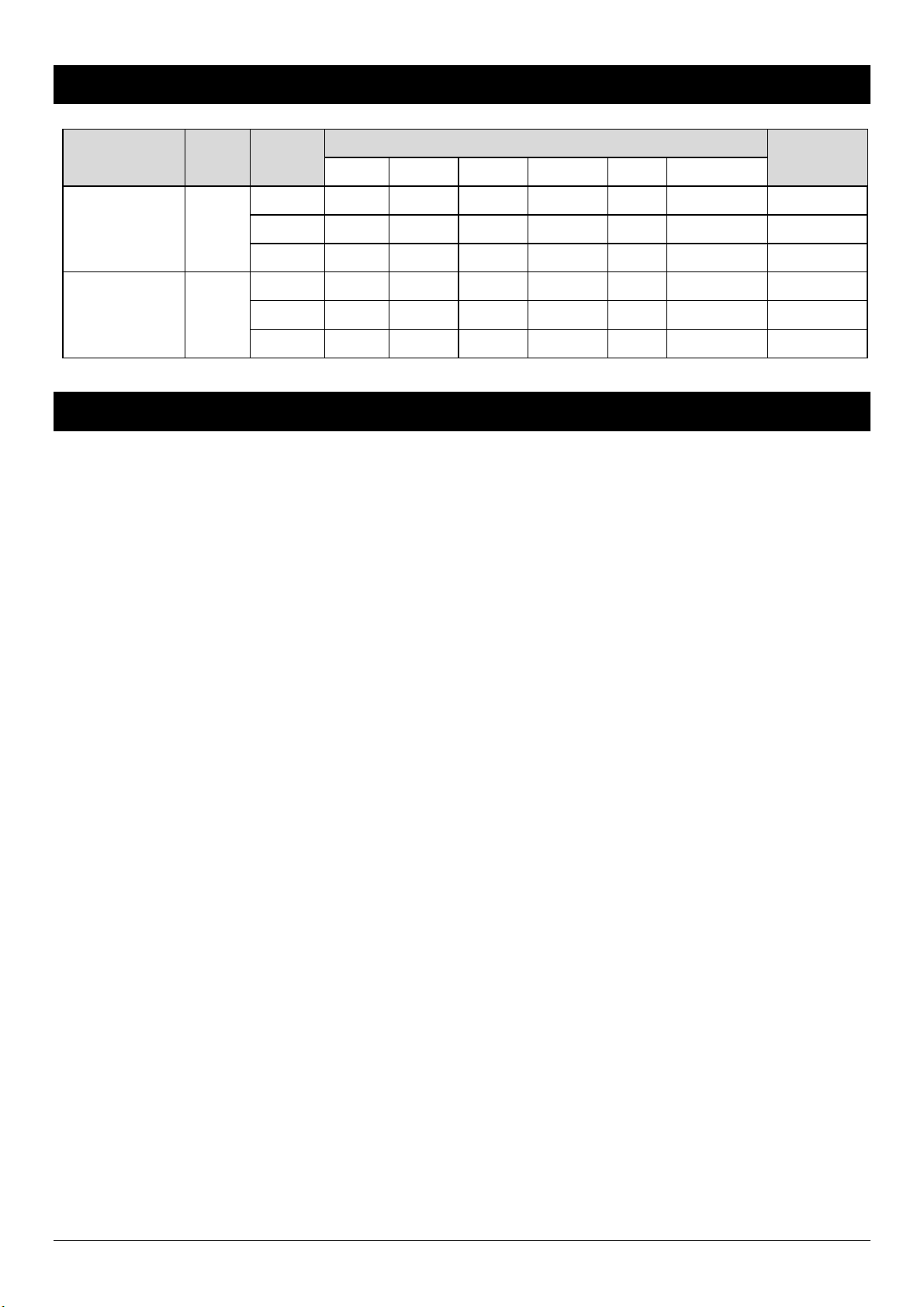

PERFORMANCE

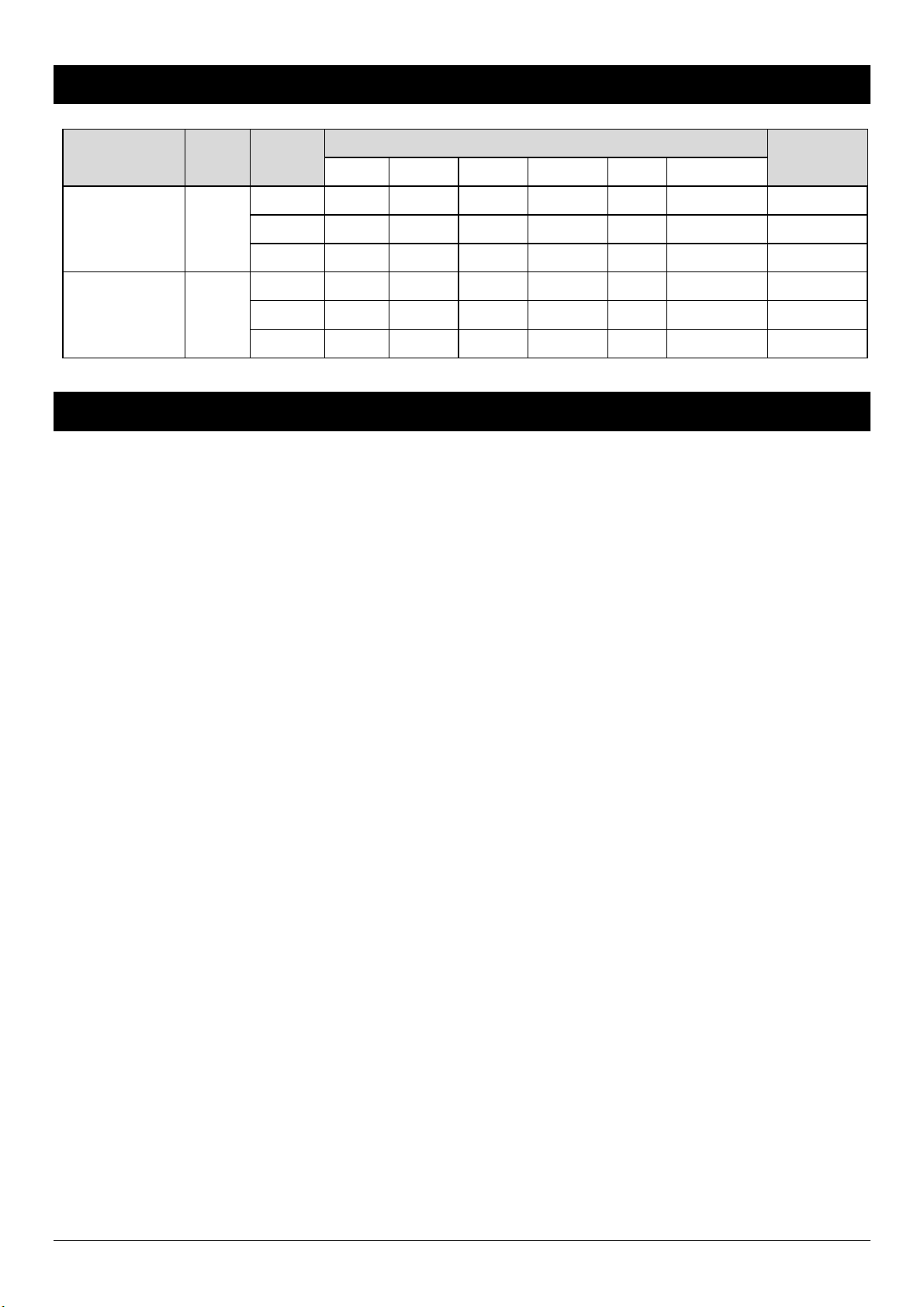

SKU HP RPM GPM of Water @ Total Feet of Lift Max. Lift

0 ft. 10 ft. 20 ft. 30 ft. 40 ft. 50 ft.

PPV10001SPK 1

3500 72.0 65.0 56.0 44.0 25.0 / 48 ft.

2000 39.0 20.0 / / / / 16 ft.

1200 22.0 / / / / / 7 ft.

PPV15001SPK 1-1/2

3500 95.0 88.0 80.0 70.0 56.0 40.0 65 ft.

2000 50.0 32.0 7.0 / / / 22 ft.

1200 30.0 / / / / / 8 ft.

SAFETY INSTRUCTIONS

1. DANGER: Do not pump flammable or explosive liquids such as oil, gasoline, kerosene, ethanol, etc. Do not use

in the presence of flammable or explosive vapors. Using this pump with or near flammable liquids can cause an

explosion or fire, resulting in property damage, serious personal injury, and/or death.

2. DANGER: ALWAYS disconnect the power to the pump before servicing.

3. DANGER: Do not touch the motor housing during operation. The motor is designed to operate at high

temperatures. Do not disassemble the motor housing.

4. DANGER: Do not handle the pump or pump motor with wet hands or when standing on a wet or damp surface, or

in water.

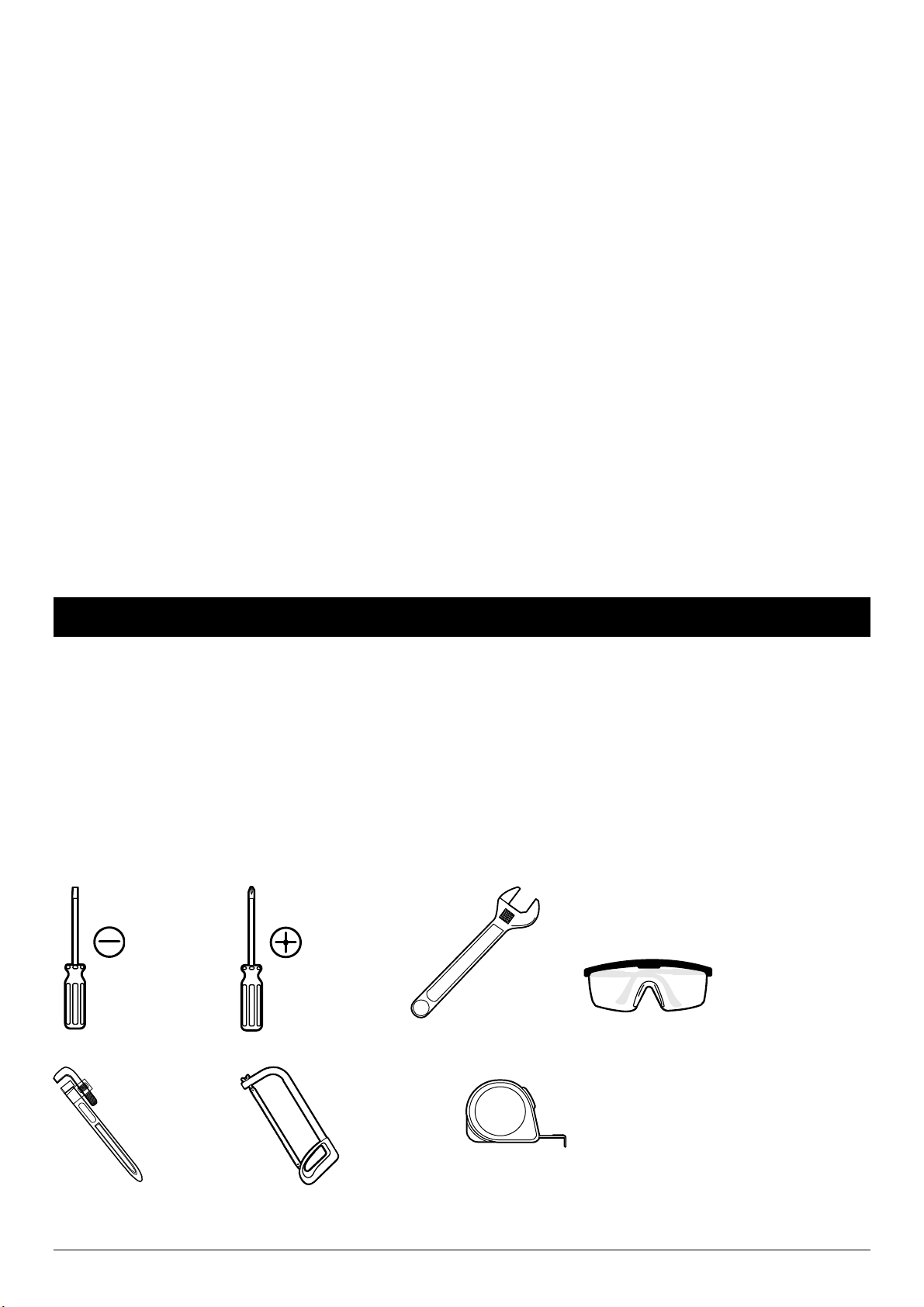

5. WARNING: Wear safety goggles at all times when working with pumps.

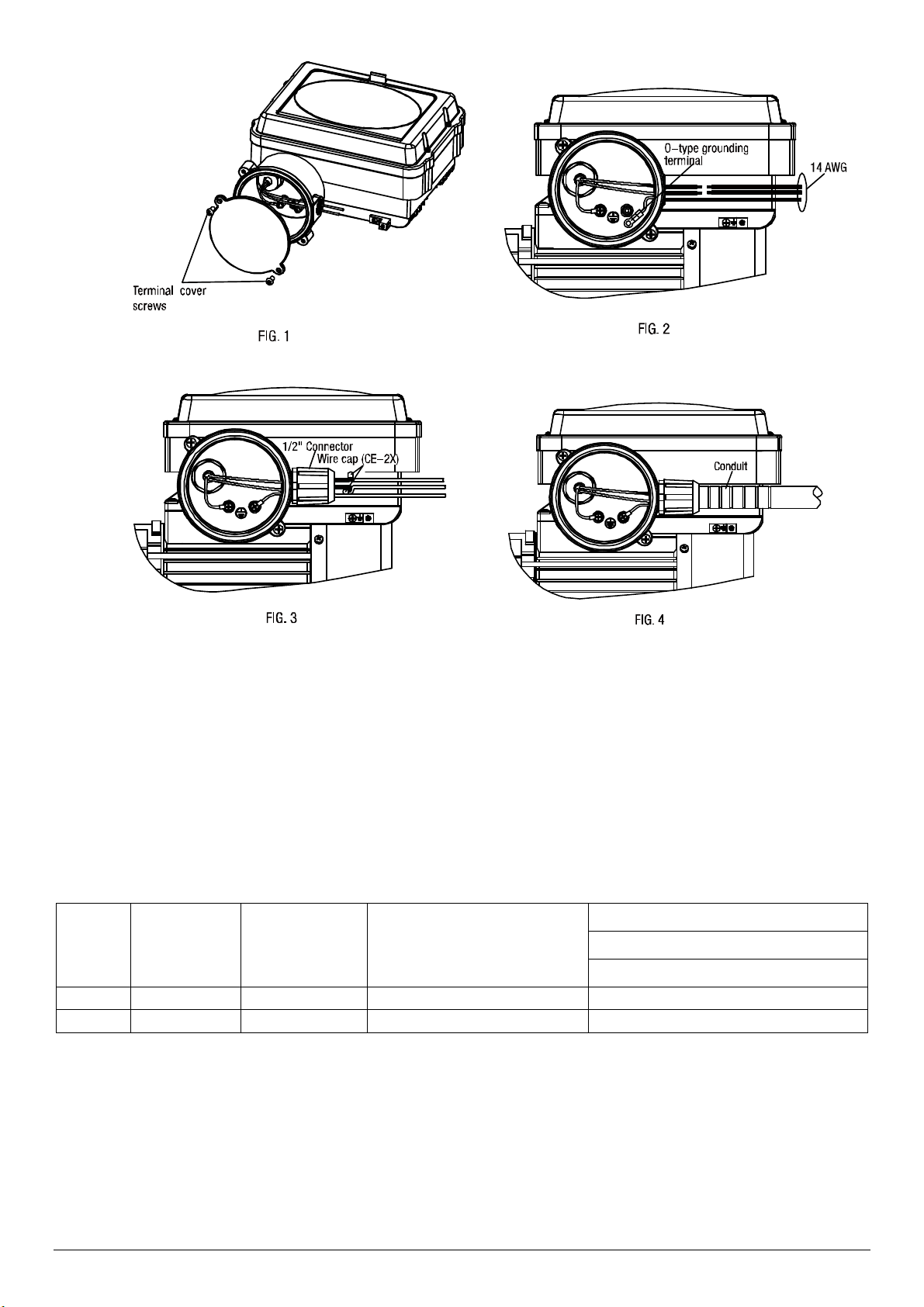

6. WARNING: This is a 230 V pump. All wiring should be performed by a qualified electrician.

7. WARNING: Protect the electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking the

cord. Do not use damaged or worn cords.

8. WARNING: Failure to comply with the instruction and designed operation of this unit may void the warranty.

ATTEMPTING TO USE A DAMAGED PUMP can result in property damage, serious personal injury, and/or death.

9. WARNING: The pump should be connected to a GFCI outlet protected with a15 amp (230V) fuse or circuit

breaker.

10. WARNING: Fire and burn hazard. Motors run at high temperatures. Do not allow leaves, debris, or foreign matter

to collect around the pump motor. Allow the motor to cool before handling.

11. CAUTION: Know the pump and its applications, limitations, and potential hazards.

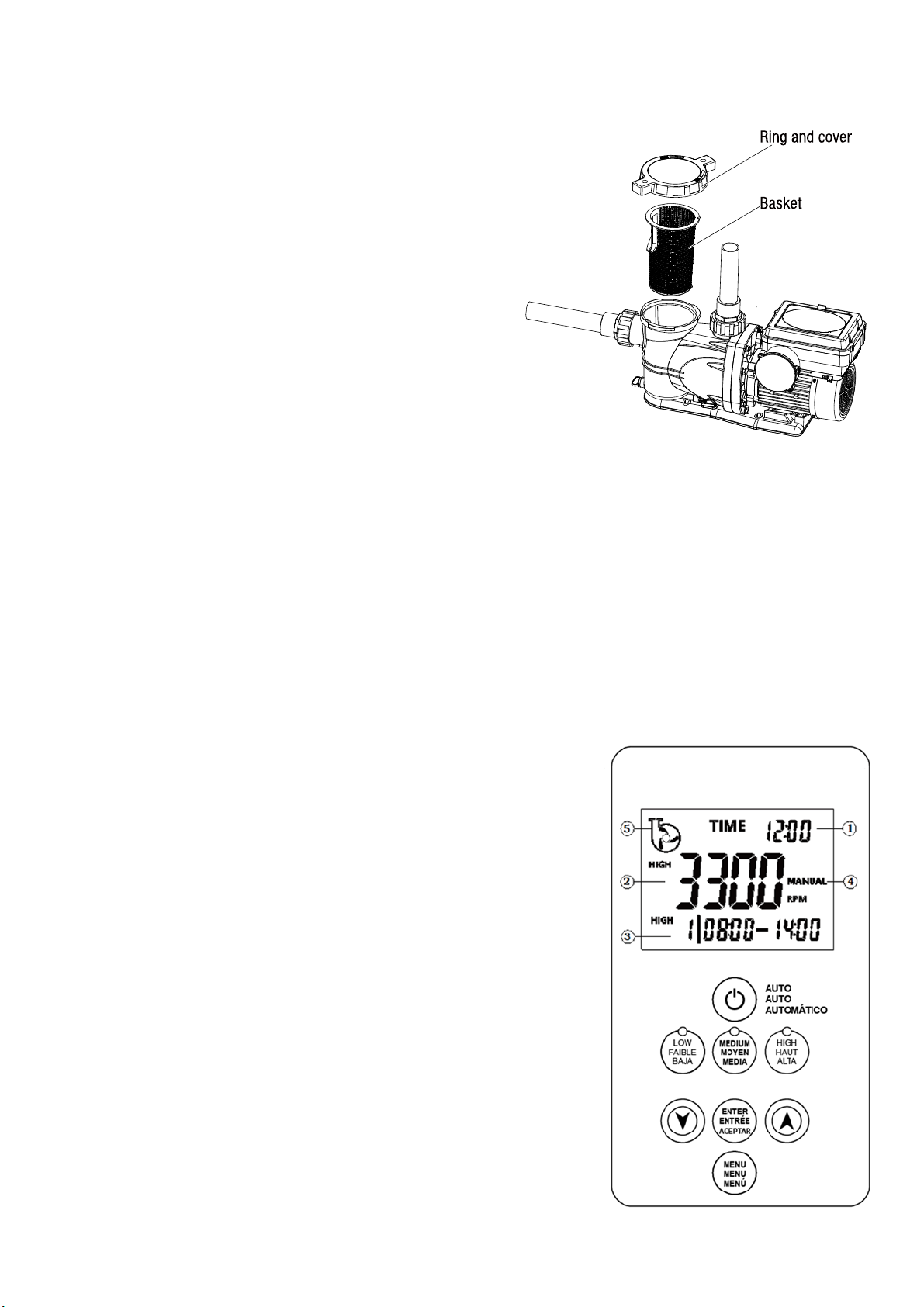

12. CAUTION: Periodically inspect the pump and system components. Disconnect the pump from the power supply

before inspecting.

13. CAUTION: Follow all local electrical and safety codes, along with the National Electrical Code (NEC). In addition,

all Occupational Safety and Health Administration (OSHA) guidelines must be followed.

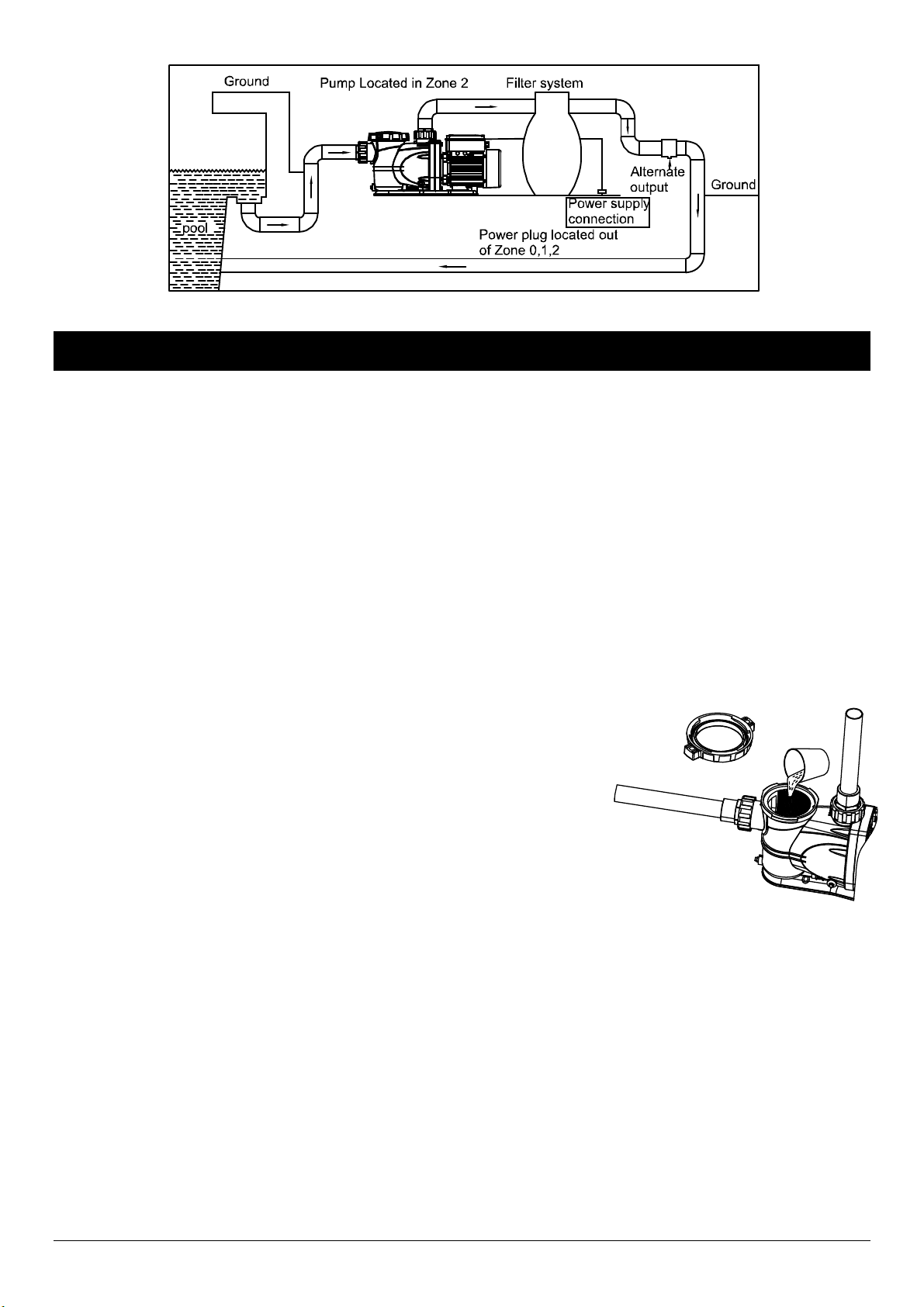

14. CAUTION: This pump is for use with permanently installed pools. Do not use with storable pools. A permanently

installed pool is constructed in or on the ground or in a building and is not intended to be disassembled or moved.

15. CAUTION: Use rigid or flexible PVC pipe. Ensure pipe ends are clean and free of any flash caused by cutting.

Use proper glue for the type of pipe selected.

16. CAUTION: Locate pump on a non-combustible surface as close to the pool/spa as possible. The surface should

be hard, level, dry, and well ventilated. The surrounding area should provide protection from the elements and

allow sufficient space for maintenance and service. Ensure the drainage will flow away from the pump. To reduce

vibration and pipe stress, use anchor bolts to secure the pump base to the surface.