Page 2 of 15

Read these instructions before operating the pool and spa pump.

Please pass these instructions on to the owner of this equipment.

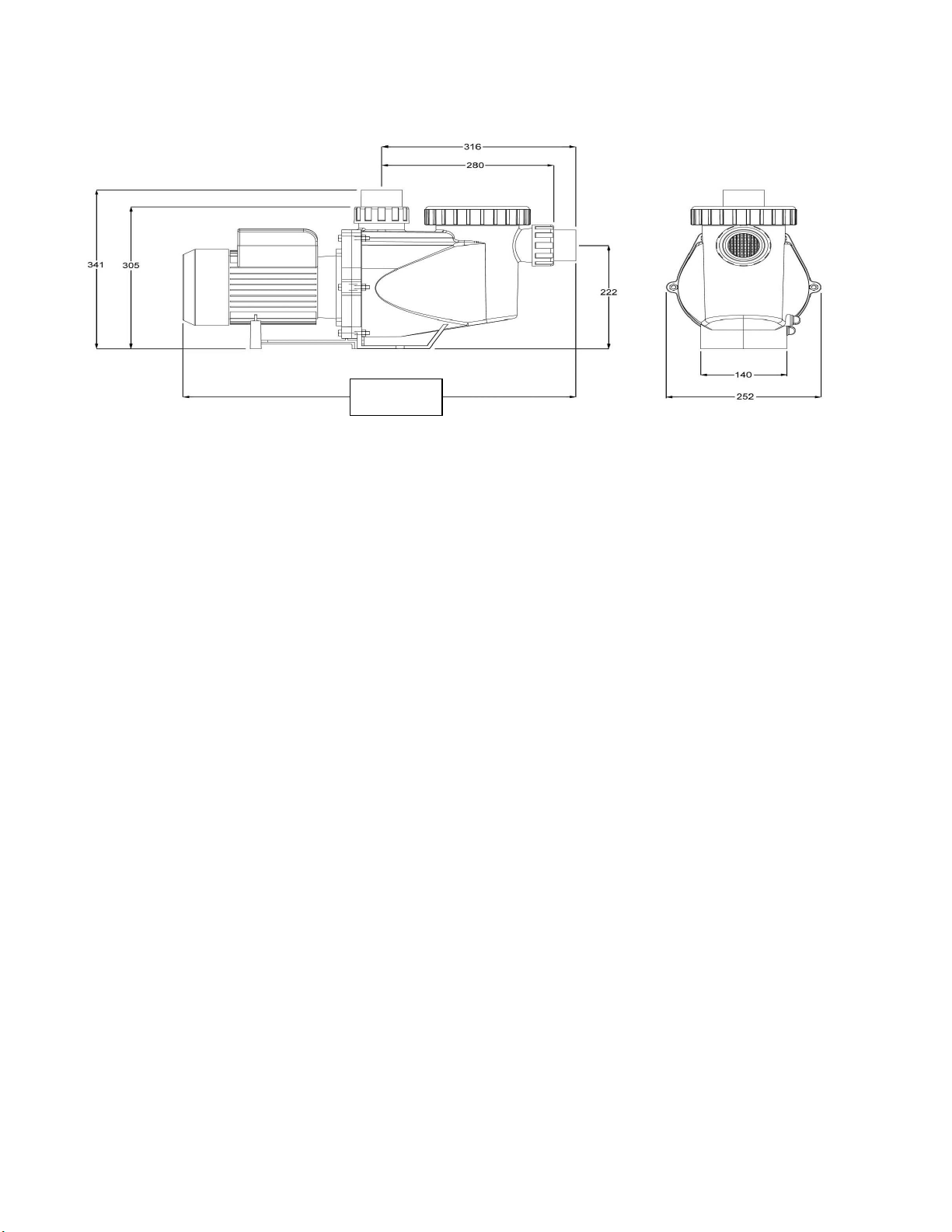

MODEL: TVS Pro 1.25hp and 1.75hp

DANGER - HAZARDOUS SUCTION.

Do not block water entry into filtration system with any part of your body as the suction can trap hair

or body parts, causing severe injury or death. Do not block suction. Turn off pump immediately if

someone becomes trapped.

Careful Reminder

This appliance is not intended for use by persons (including children) or person/s with reduced

physical, sensory or mental incapability’s, or lack of experience and knowledge, unless they have

supervision or instruction concerning use of the appliance by a person responsible for their safety.

Please check your pump basket, skimmer and entire pool system regularly to maximize the life of

your pool equipment & personal safety. Turn pump off first before checking baskets.

Make sure that all pressure gauges installed are in working condition and the operating pressure is

within limits as specified on the product.

Make sure that each suction inlet, and main drain has a cover that is securely attached and in safe

working condition to meet with all current legislation.

Make sure that all skimmer covers (deck lids) are securely attached and in safe working condition.

These should be replaced every 3 to 4 years.

Remove any obstructions or debris from the main drain cover.

Ensure the skimmer baskets and the pump hair and lint pots are free of leaves and debris at regularly.

Remove obstructions and combustibles from around the pump motor.

Make sure all wiring connections are clean and that all wiring and electrical equipment is in good

condition. Damaged wiring must be repaired or replaced by a qualified electrician as soon as damage

is discovered.

Do not add chemicals directly to the pool skimmer. Adding undiluted chemicals may damage pump,

heater, etc and void warranty.

Check water balance and sanitizer levels at your local pool shop.

WARNING!

CHILDREN SHOULD BE SUPERVISED AT ALL TIMES TO ENSURE THAT DO NOT PLAY WITH THE PUMP

OR ANY POOL ASSOCIATED ELECTRICAL DEVICE

Pump suction is hazardous and can cause entrapment, drowning or disembowel bathers.

Do not block or cover any pool/spa suction.

Do not use or operate swimming pools, spas or spa baths if a suction cover is broken, missing or

loose.

Suction covers and inlets must be installed as per Australian Standards guideline and provided for

every pump to avoid suction entrapment.

CAUTION!

In the interest of safety, we advise that all brands and types of pool pumps must be installed in

accordance with AS3000 wiring rules or equivalent

If the pump and filter are located below pool water level, it is necessary to fit isolating valves in the

pipe between the pump and the skimmer box and in the return pipe from the filter to the pool.

The fittings on this product are constructed of ABS. Some PVC jointing compounds are incompatible

with ABS. Check compound suitability before use.