Issue: May 2023 Contents Page 1

MAIN CONTENTS

Section A –Introduction Page

Technical data ............................................................................................................................................... A.1

Safety precautions......................................................................................................................................... A.1

Contents of each Clearflow flushing kit .......................................................................................................... A.1

Section B –Using the Clearflow pump for power flushing Page

Introduction ...................................................................................................................................................B.1

System inspection and preparation.................................................................................................................B.1

Location and connection of the Clearflow pump .............................................................................................B.2

Initial flushing procedure (water only) ............................................................................................................B.4

Chemical flushing procedure –which chemical to use.....................................................................................B.6

Chemical flushing procedure –using PowerFlush FX2 .....................................................................................B.7

Chemical flushing procedure –using HyperFlush.............................................................................................B.9

Inhibitor and corrosion protection................................................................................................................B.10

Upon completion..........................................................................................................................................B.10

Quick guide to power flushing ......................................................................................................................B.11

Summary of chemicals used when power flushing ........................................................................................B.12

Radiator valve settings..................................................................................................................................B.13

Power flushing survey and check list.............................................................................................................B.14

Power flush monitoring form........................................................................................................................B.16

Section C –Frequently Asked Questions (FAQs) about power flushing Page

Questions and answers...................................................................................................................................C.1

Section D –Using the Clearflow for descaling boilers and heat exchangers Page

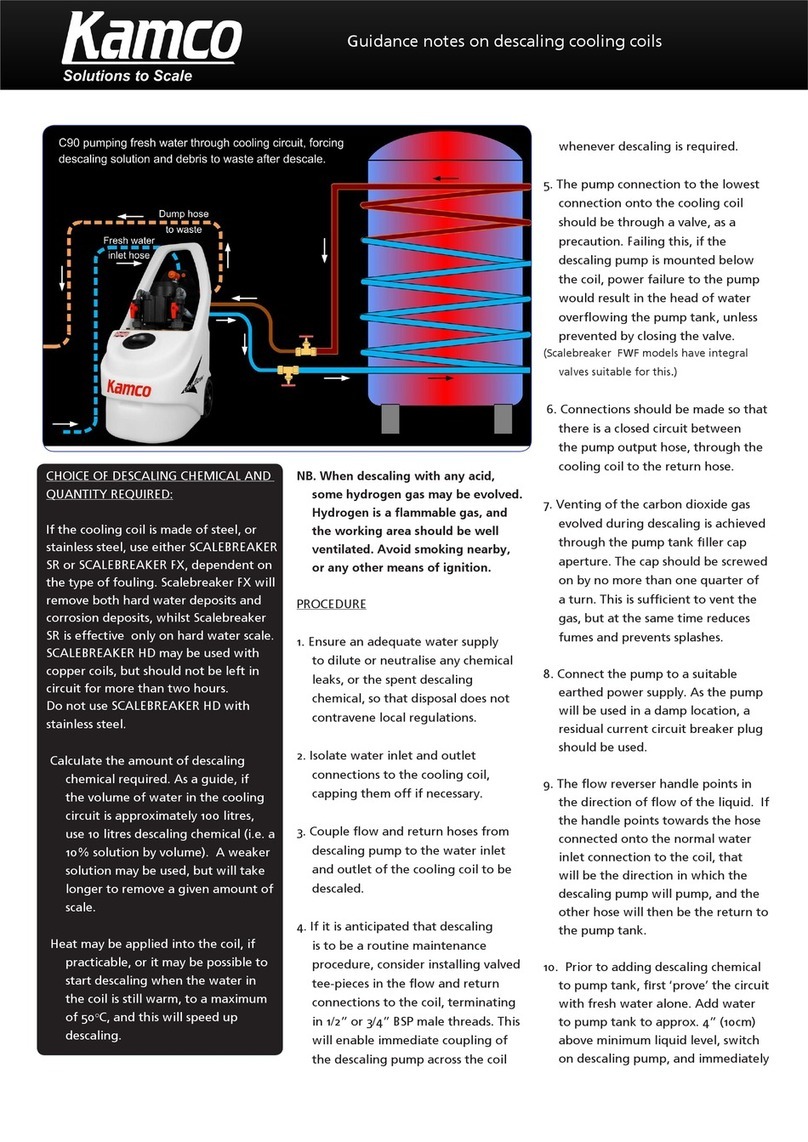

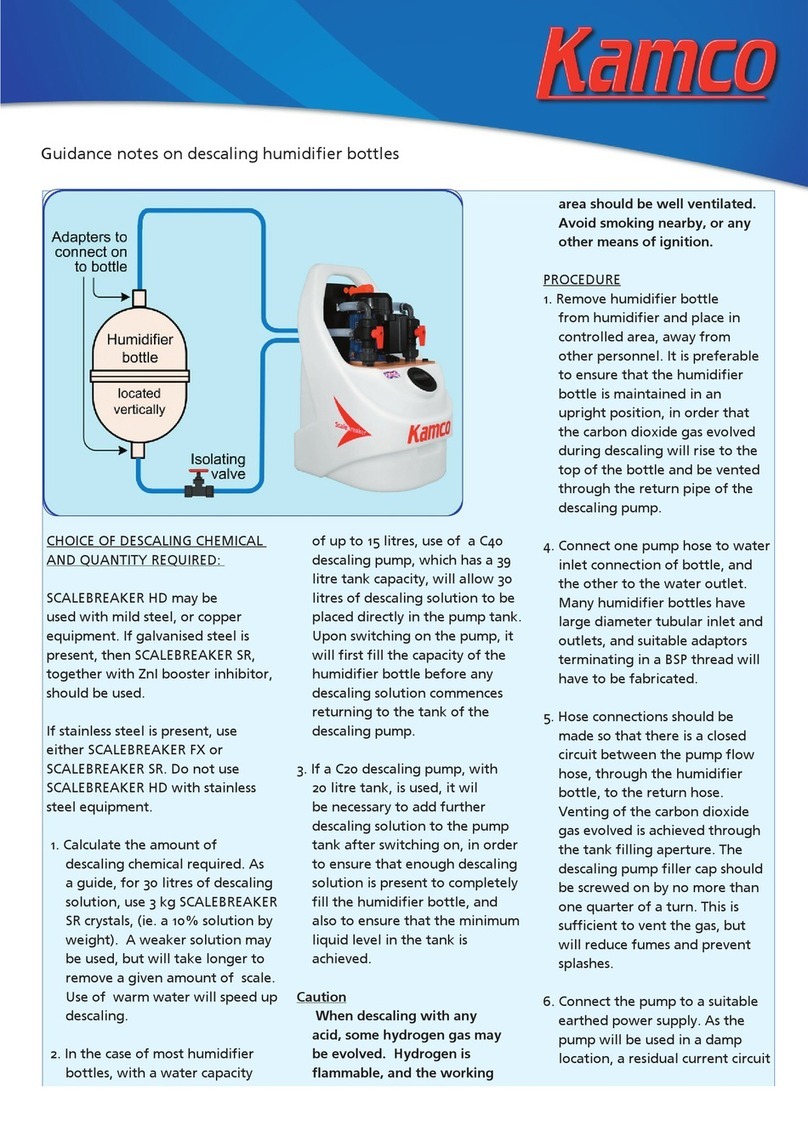

Descaling procedure...................................................................................................................................... D.1

Summary of chemicals used when descaling.................................................................................................. D.2

Section E –Service and repair Page

Trouble shooting and performance testing .....................................................................................................E.1

Trouble shooting flow chart............................................................................................................................E.2

CF40 & CF90 exploded view, spares diagram and spares list............................................................................E.3

CF210 Exploded view, spares diagram and spares list......................................................................................E.8

Section F –Optional power flushing accessories Page

Introduction ...................................................................................................................................................F.1

CP2 circulator pump body adapter..................................................................................................................F.2

IK6 Systemsure injector / spray....................................................................................................................... F.2

CombiMag power flushing filter......................................................................................................................F.6

CombiMag Split Twin power flushing filter......................................................................................................F.8

CombiMag Dual Digital power flushing filter and heater ................................................................................. F.9

Plate heat exchanger adapters...................................................................................................................... F.10

Radhammer radiator vibration tool............................................................................................................... F.11

Electronic test equipment –infra-red thermometer...................................................................................... F.12

Electronic test equipment –pH meter .......................................................................................................... F.13

Electronic test equipment –TDS meter......................................................................................................... F.14

Turbidity tube............................................................................................................................................... F.15

Water analysis test kit .................................................................................................................................. F.16

Additional water treatment chemicals .......................................................................................................... F.17

Section G –How to contact and locate Kamco Page

Helpline, e-mail, and website......................................................................................................................... G.1

Location map................................................................................................................................................. G.1

Section H –Warranty Page

Warranty....................................................................................................................................................... H.1