corresponding to the RX input is required (if an RSW control unit is used, a BNC connector).

Important notes: The TNC fittings should be tightened securely to ensure watertightness. Normally,

manual force should be sufficient (always ensure axial alignment / easy screwability without tilting the

connector!). If the force is too low (children, dainty adults, incomplete usability of the hands, ...), pliers can

be carefully used for help. However, excessive force must never be exerted, as this could damage the

seals or even the thread of the connector! Also, the sockets in the housing must not be twisted, because

otherwise their sealing can be destroyed and the internal connections can tear off!

Never turn TNC connectors against each other! Only the union nut may be turned, never the plug

against the socket!

Reason: In the plug (the connector on the cable, in RP-TNC this is actually a socket) has spring elements

slotted in the axial direction. These press firmly against the corresponding contact surface of the socket

when the plug is inserted. If the plug is rotated in the process, the sharp-edged slots literally mill off the

contact surface of the socket.

So never, for example, apply the plug only slightly, so that the union nut just attaches, and then turn the

whole cable with plug and union nut on the socket. This is relatively easy because you can use the cable

as a lever. But it damages the spring elements and the socket!

Correct: Press the plug firmly onto the socket (push axially only, i.e. in the longitudinal direction!) until the

threads of the union nut and socket are against each other. Then unscrew the nut as far as easily

possible. Then push the plug on further, again turn the nut a little further and continue alternately in this

way until no further pushing on / turning of the nut is possible.

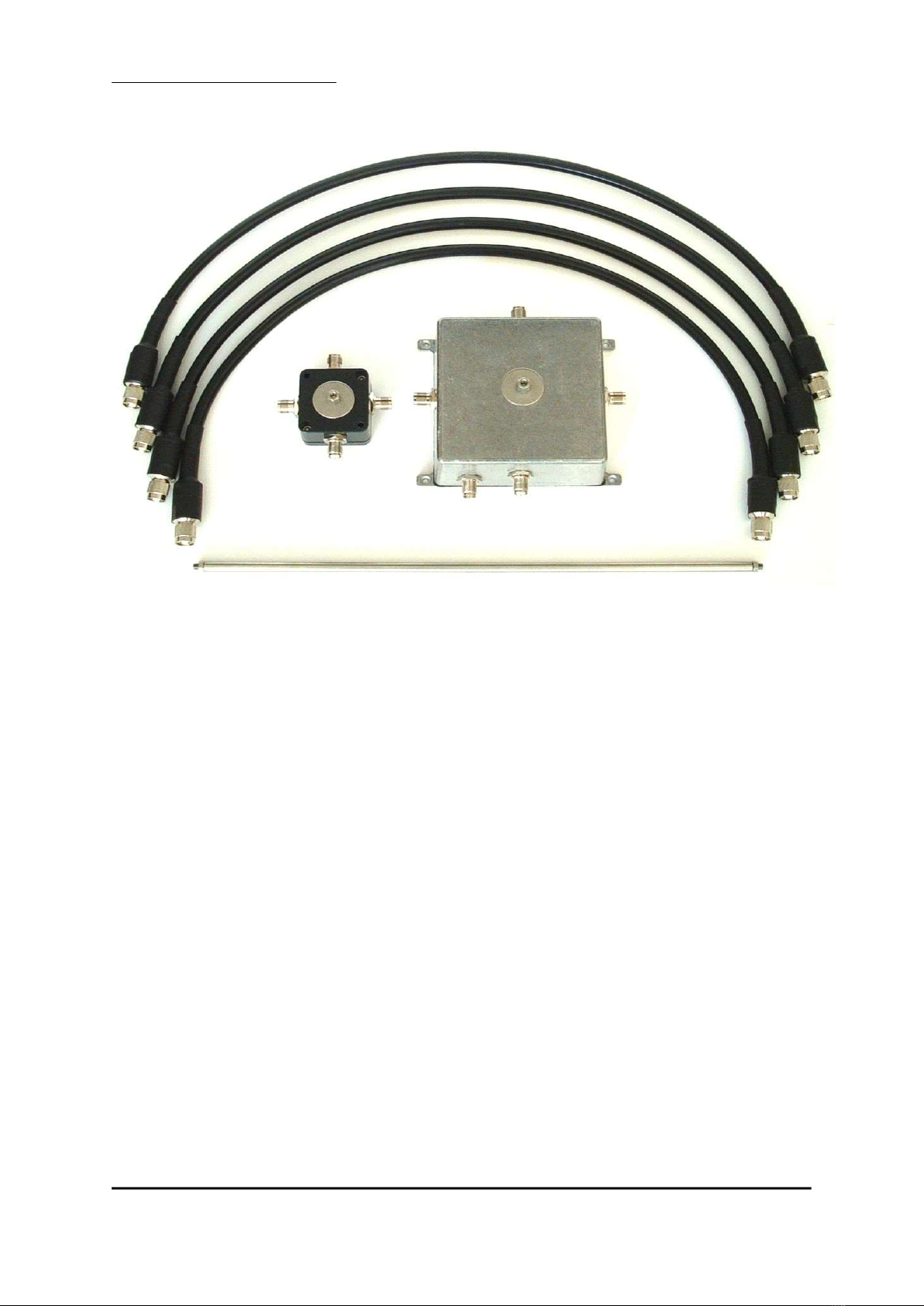

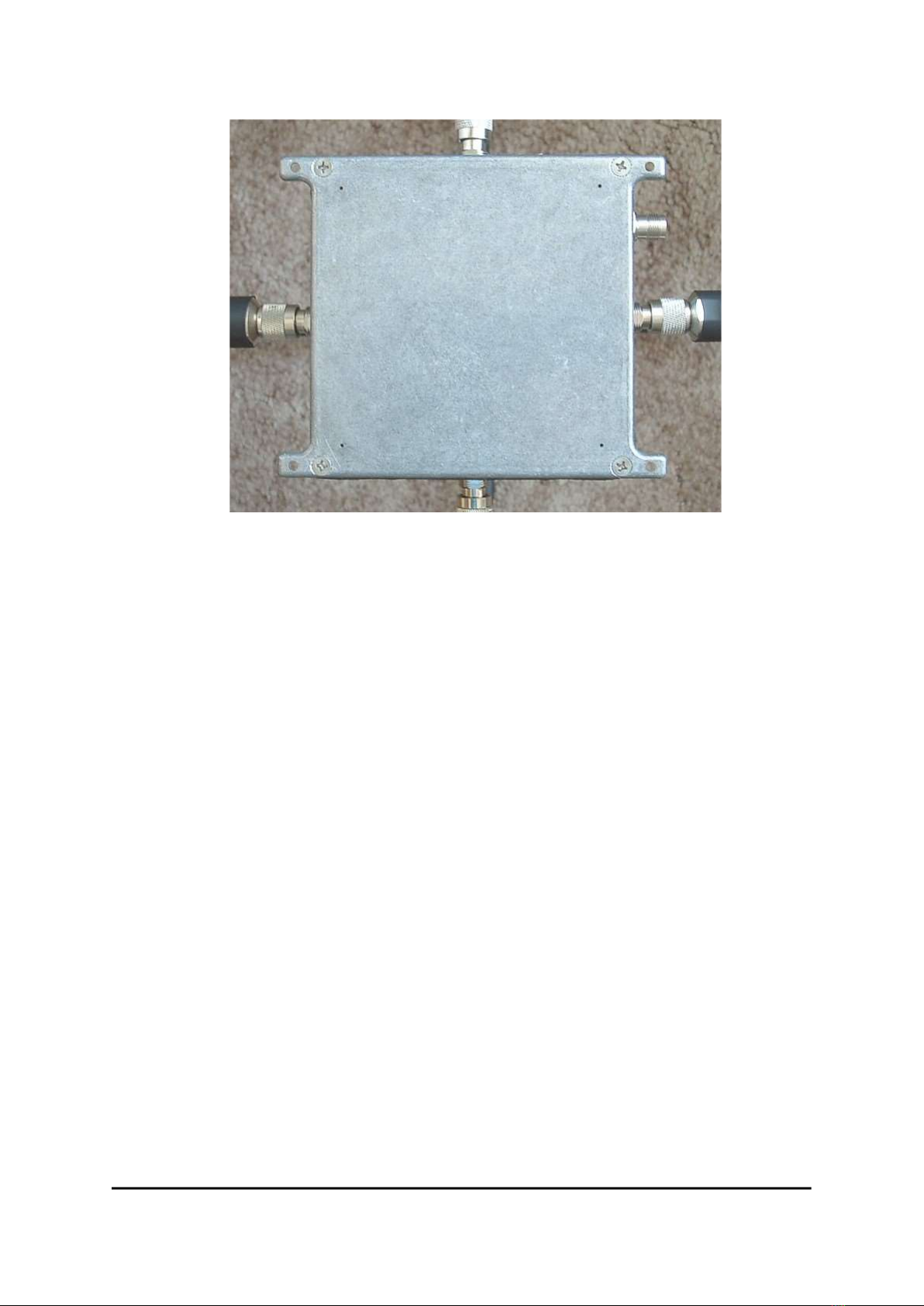

The most sensible thing to do with the RLA4G is to start by lightly screwing the cables to the top connector

housing and letting them hang straight down near the sockets on the amplifier housing. Then plug on there

as described and screw on tightly. Then tighten completely at the top. In this way, rotation of the plugs in

the sockets can be largely avoided.

After assembly, the shape of the coaxial cable can be straightened out a bit. Usually, the loops

automatically have a slightly "wobbly" shape because the upper housing is smaller than the amplifier

housing. Also, the cables are rarely exactly straight. This can be easily recognized by looking at the

connecting rod and, if necessary, straightening the cable accordingly. However, all these are purely

aesthetic flaws, the function of the antenna is not affected.

If the TNC connectors are dismantled and reassembled frequently, they should only be screwed on far

enough to ensure stable contact (protection of the threads). The connectors are made of brass, which likes

to jam a bit with wear. It is then helpful to use a small amount of acid-free grease (e.g. silicone grease).

If the antenna is likely to never be dismantled again, sealing the connectors by wrapping them with self-

vulcanizing sealing tape is highly recommended. Caution, pay attention to UV-stable material!

In case of strong wind load, the tip of the antenna (upper part with node housing) may start moving. All

internal connections are made with flexible strand, so that these small movements are absorbed.

Nevertheless, they put a strain on all components (especially the connection to the aluminum amplifier

housing), which can lead to material fatigue over time. In this case, the tip of the antenna should be

intercepted by attaching a support to the upper screw connection of the center pole to the node housing

(e.g. thick sheet metal strip with 5 mm hole guided laterally to a pole).

VERSION DATE NAME K & M Burkhard Reuter Page 7 of 8

1.4 24.11.2021 B. Reuter RLA4G/GS