FUEL TANK

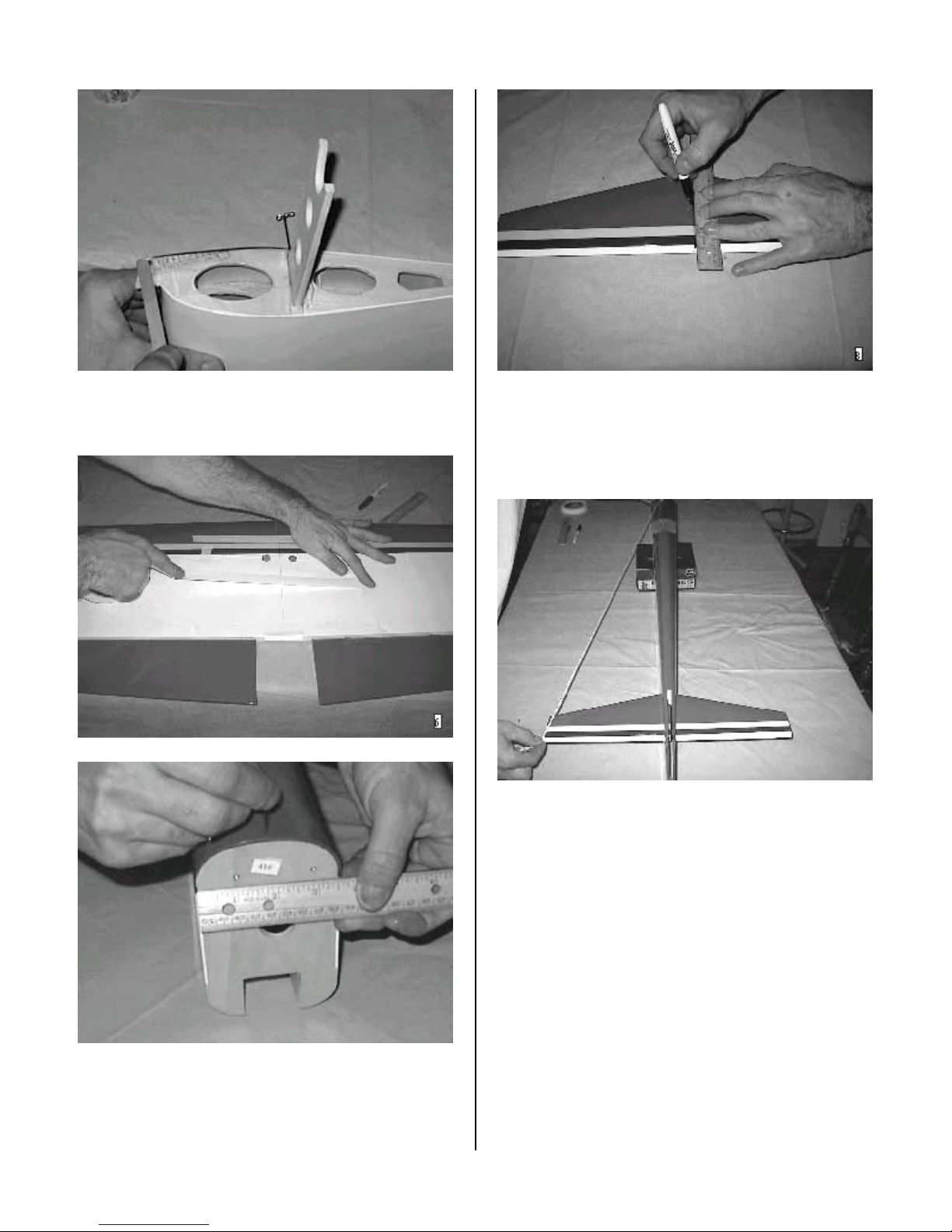

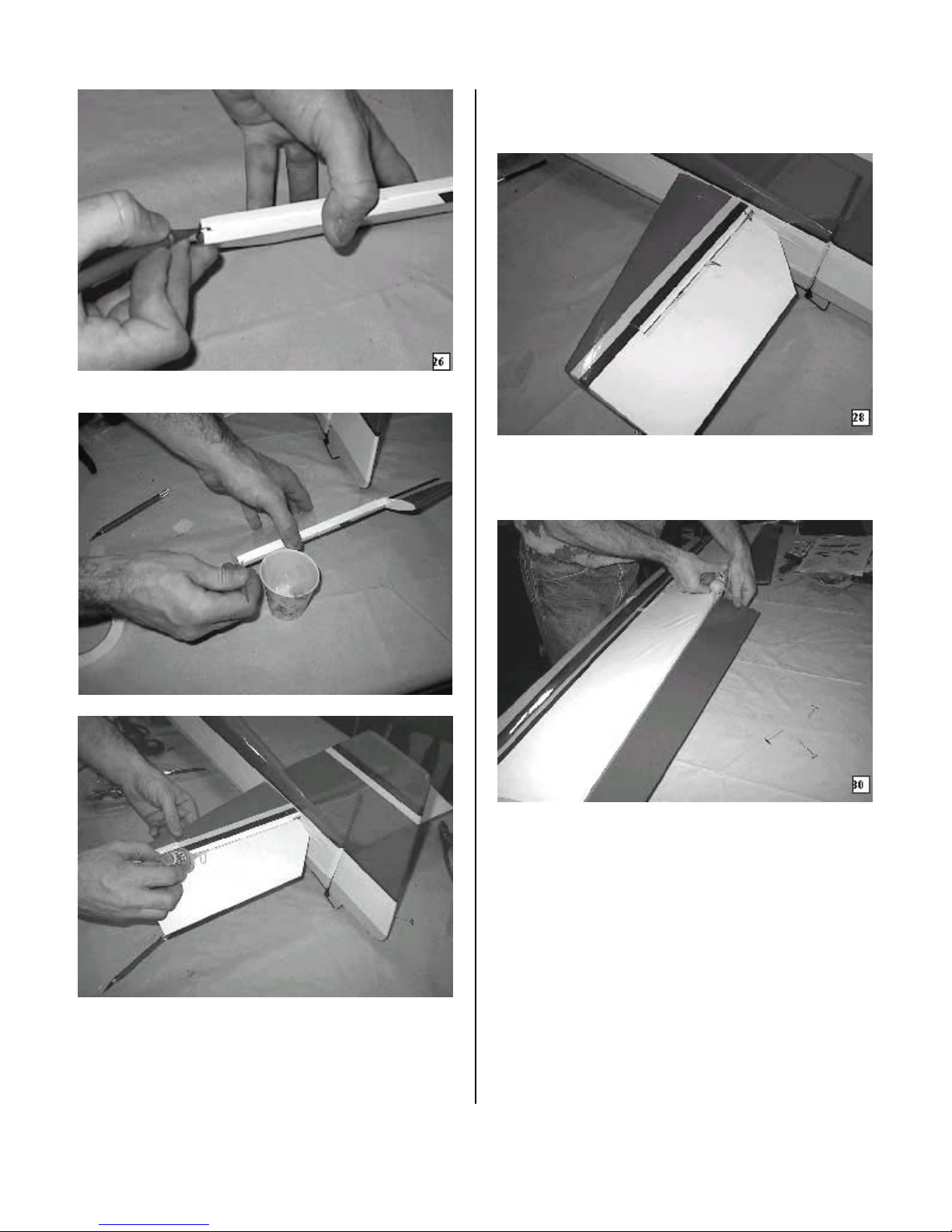

Pass the two metal tubes through the silicone

stopper. Place the large endplate on the outside

and the small endplate on the inside. Press the

screw through the outer plate and through the

silicone stopper, screw it into the inner plate do

not tighten. Slide the metal tubes so 1/2-inch

extends past the outer side of the silicone stopper.

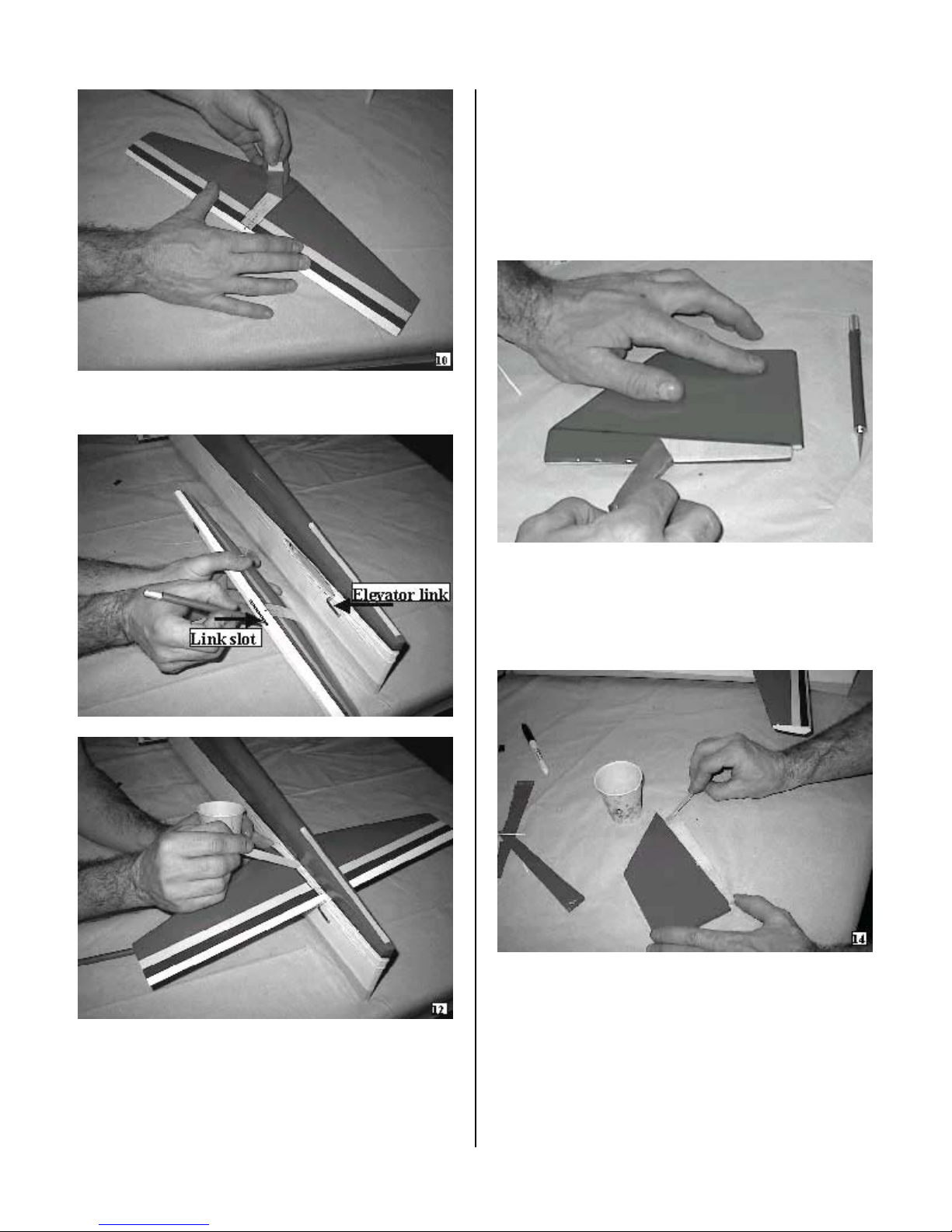

Gently bend the long tube up to point into the

“bubble” at the top of the tank. Push the flop

weight into one end of the silicone tube. Cut the

tube so that when the other end is pushed on the

short metal tube the flop weight will be

approximately 3/8-inch from the back of the tank.

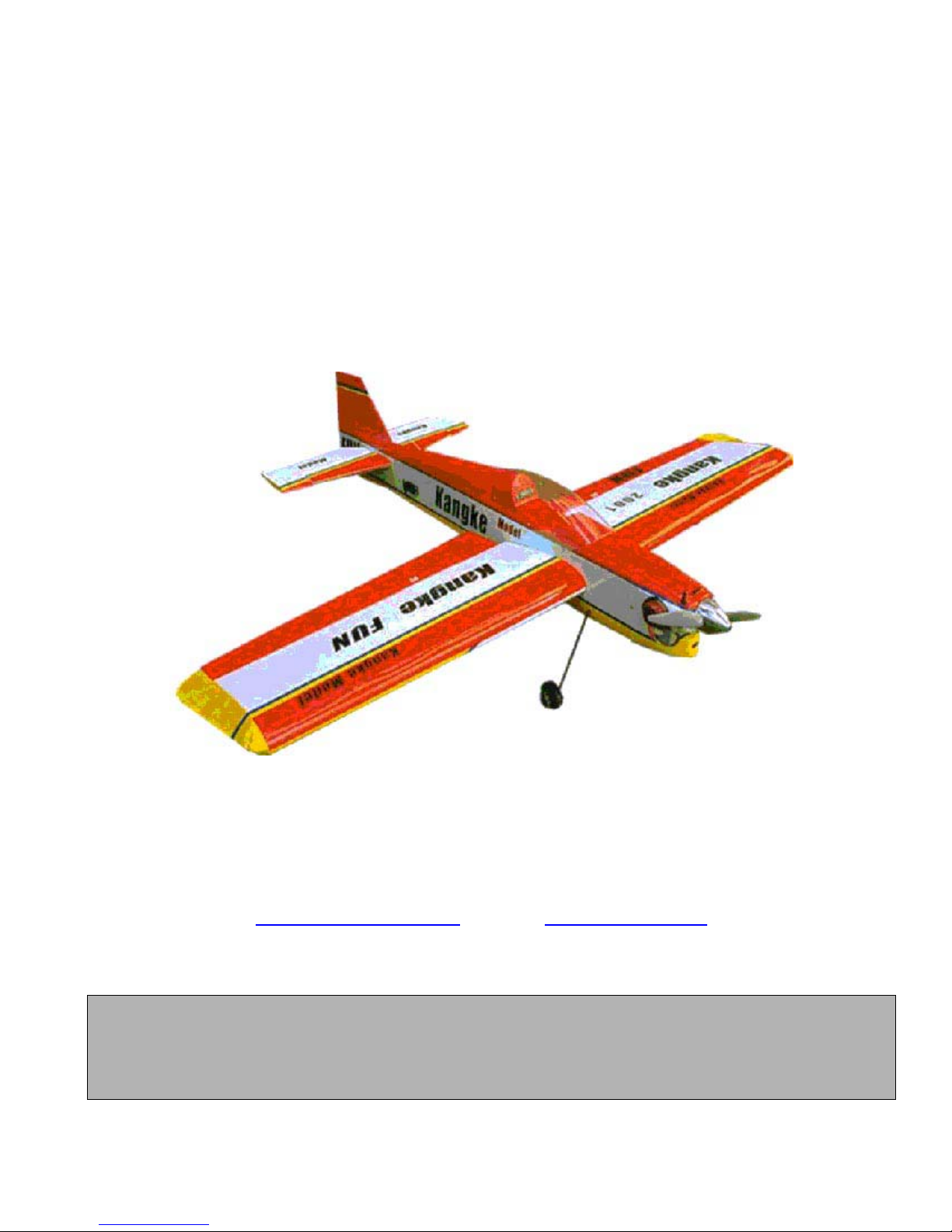

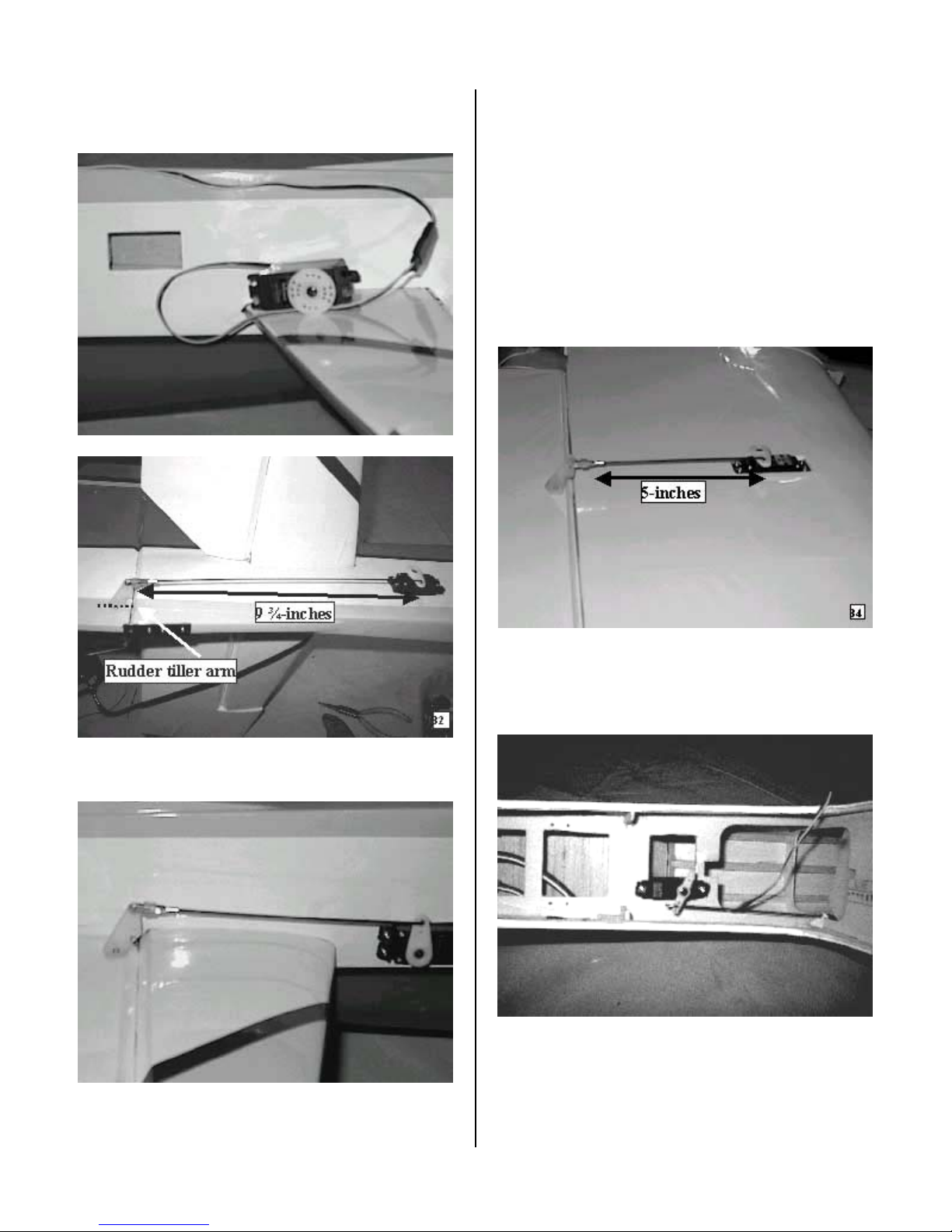

Slide the assembly into the tank, making sure to

get the vent tube in or near the top. Tighten the

screw until the stopper is tight in the opening. It is

best to label the vent and carb lines with a felt tip

marker on the outer plate to avoid confusion later.

Apply a 1/4-inch bead of RTV silicone around

the tank stopper.

Slide the fuel tank into position, wedge a piece of

foam in at the rear of the tank to hold it in

position. Allow the RTV to cure.

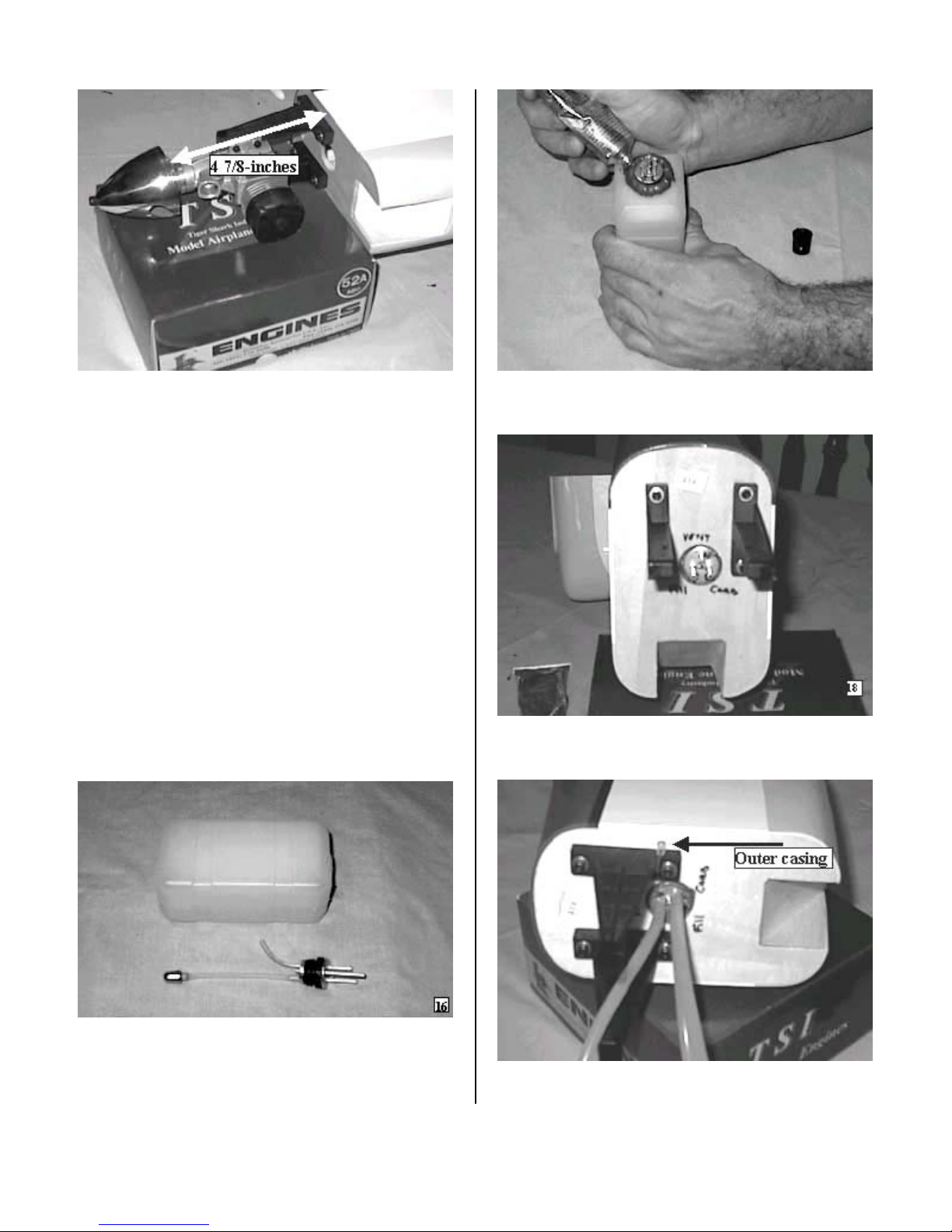

Drill a hole in the firewall and install the throttle

wire outer casing.

Install the fuel lines.

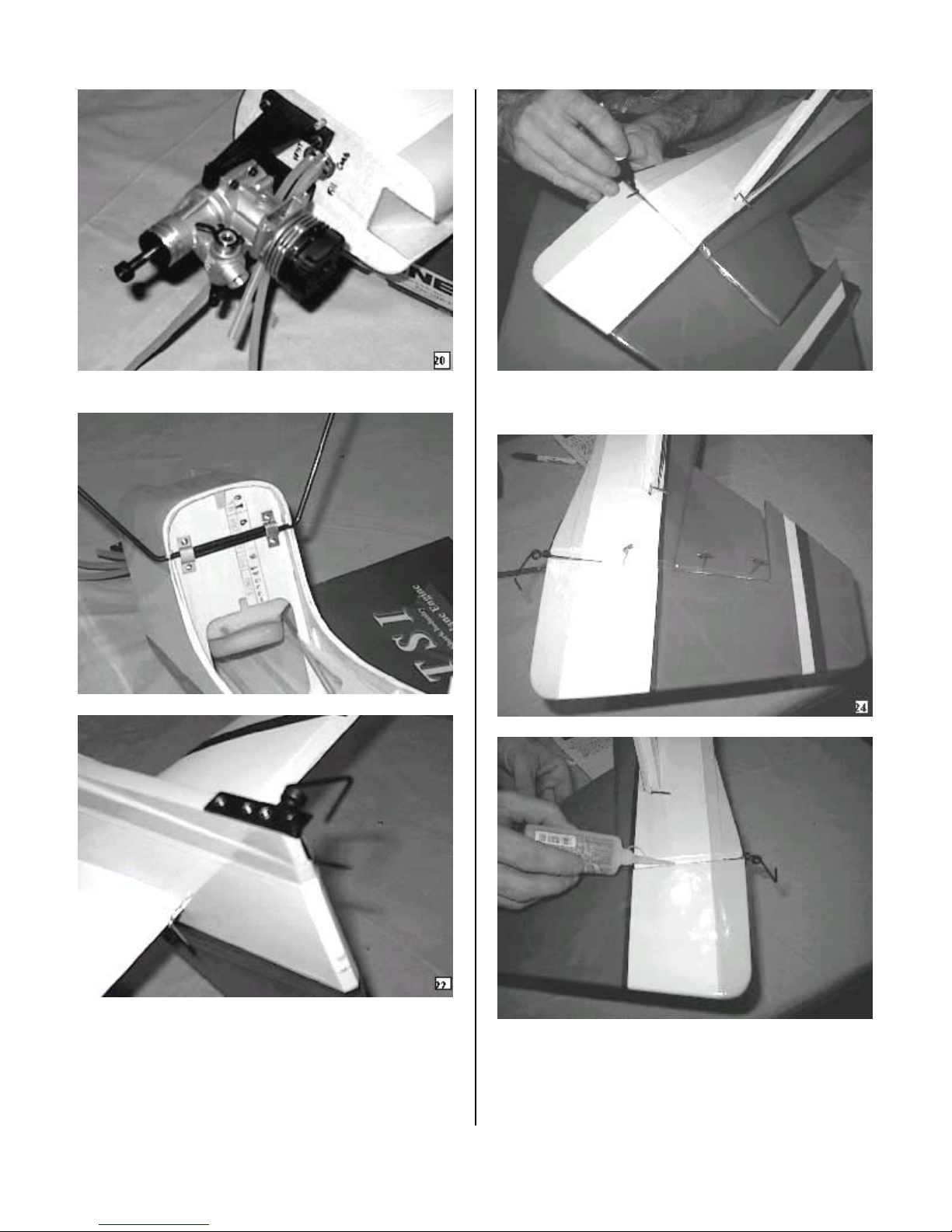

Install the engine with the supplied screws and

lock nuts.

6