Even small changes in the balance point make large

changes in stability. For your first flights we

recommend using a balance point at the forward

end of the center of gravity {C.G.} range, this

location will provide the most stability. As your

comfort and skill increase slowly move the C.G. aft

to increase the control response.

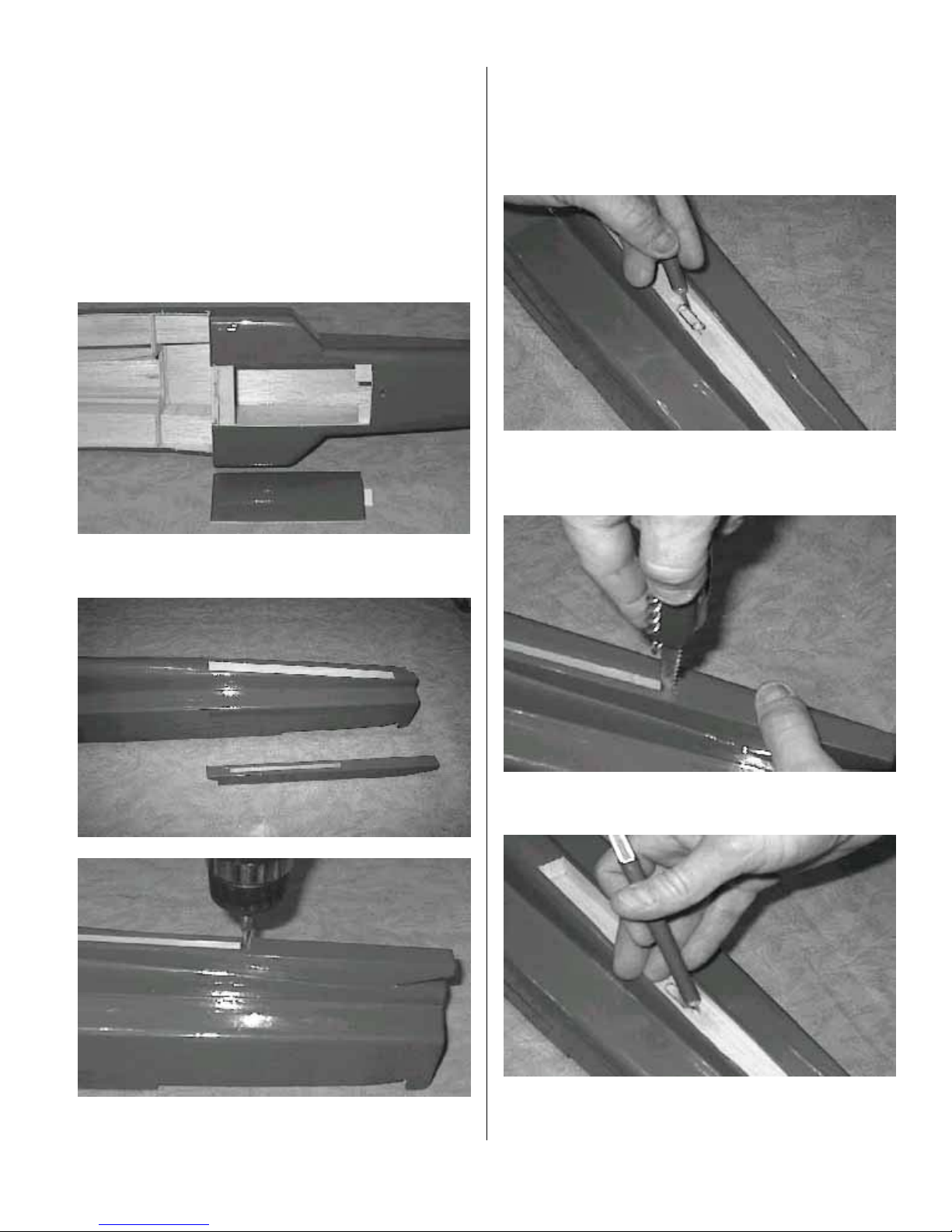

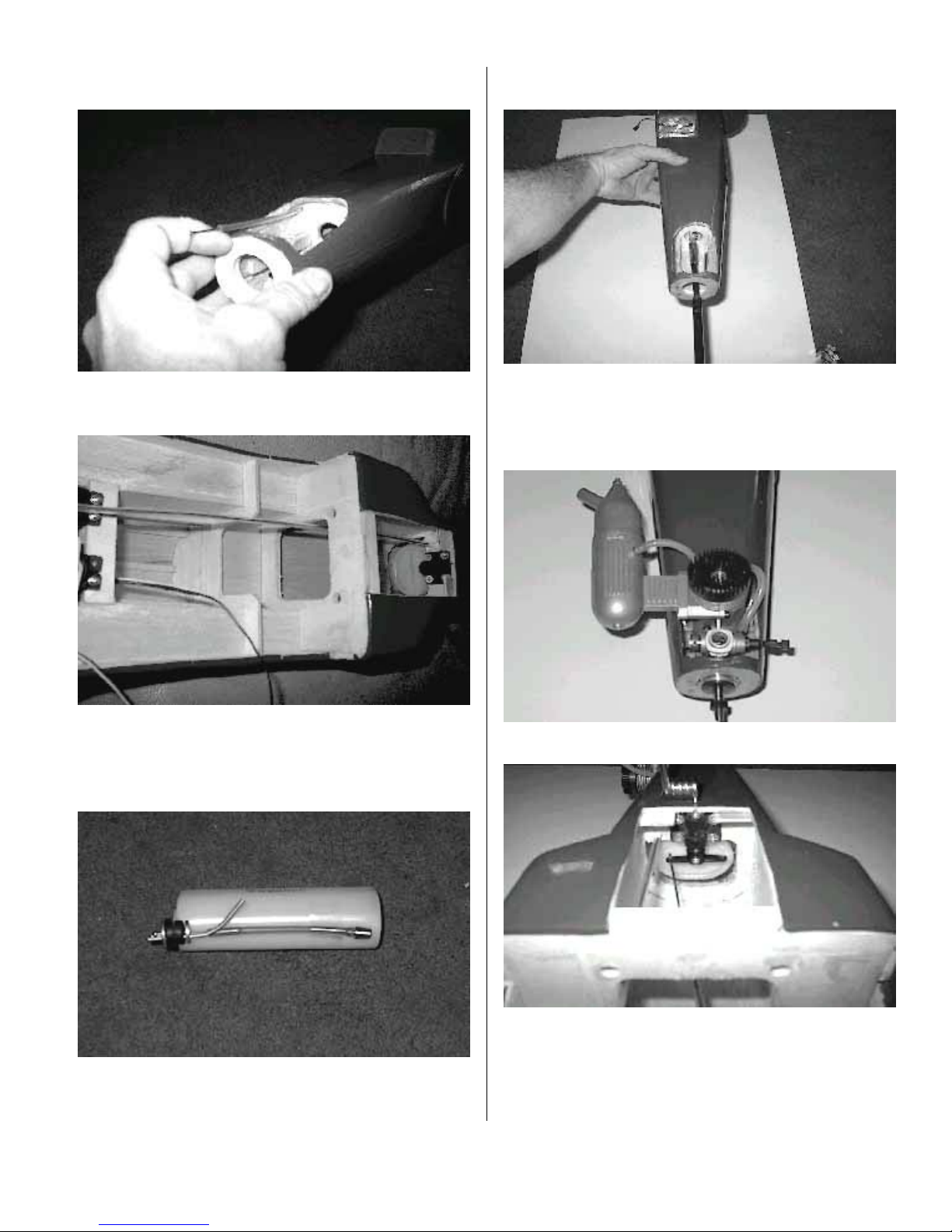

Lay a strip of masking tape along the top of each

wing as shown. Make two marks on the tape one 5

1/2-inches, one 6 1/4-inches back from the leading

edge of the wing. Repeat on the other side of the

fuselage. These marks represent the limits of the

C.G. range.

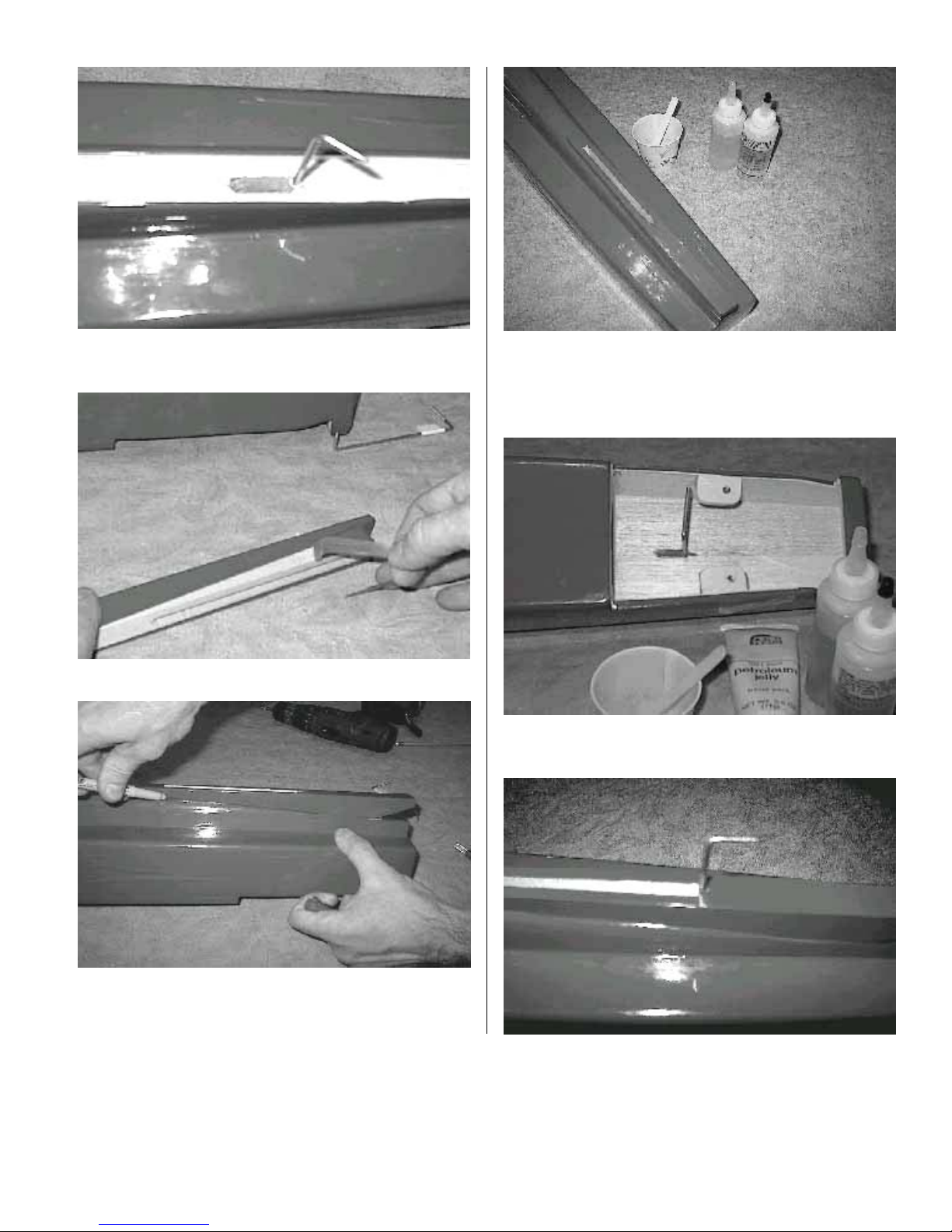

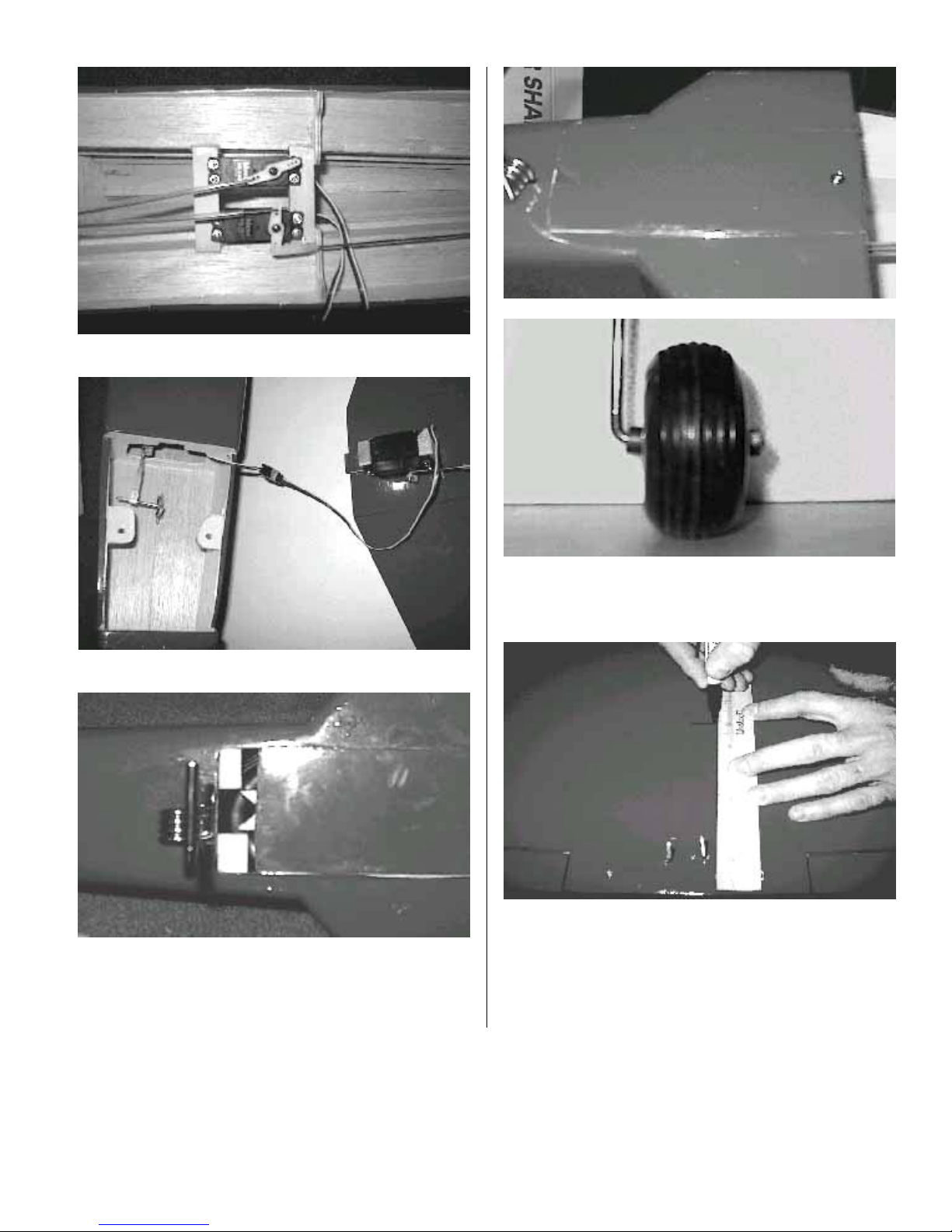

Turn the aircraft upside down and support it from

between the two marks. Slide the battery pack to a

position where the plane will balance level to

slightly nose heavy. Mount the battery inside the

fuselage at the determined location. Install the on

off switch in a convenient location per the

manufactures instructions. Reinstall the wing and

check the C.G. again. If necessary add weight to the

nose or tail.

CONTROL THROWS

Double check all controls move in the proper

direction

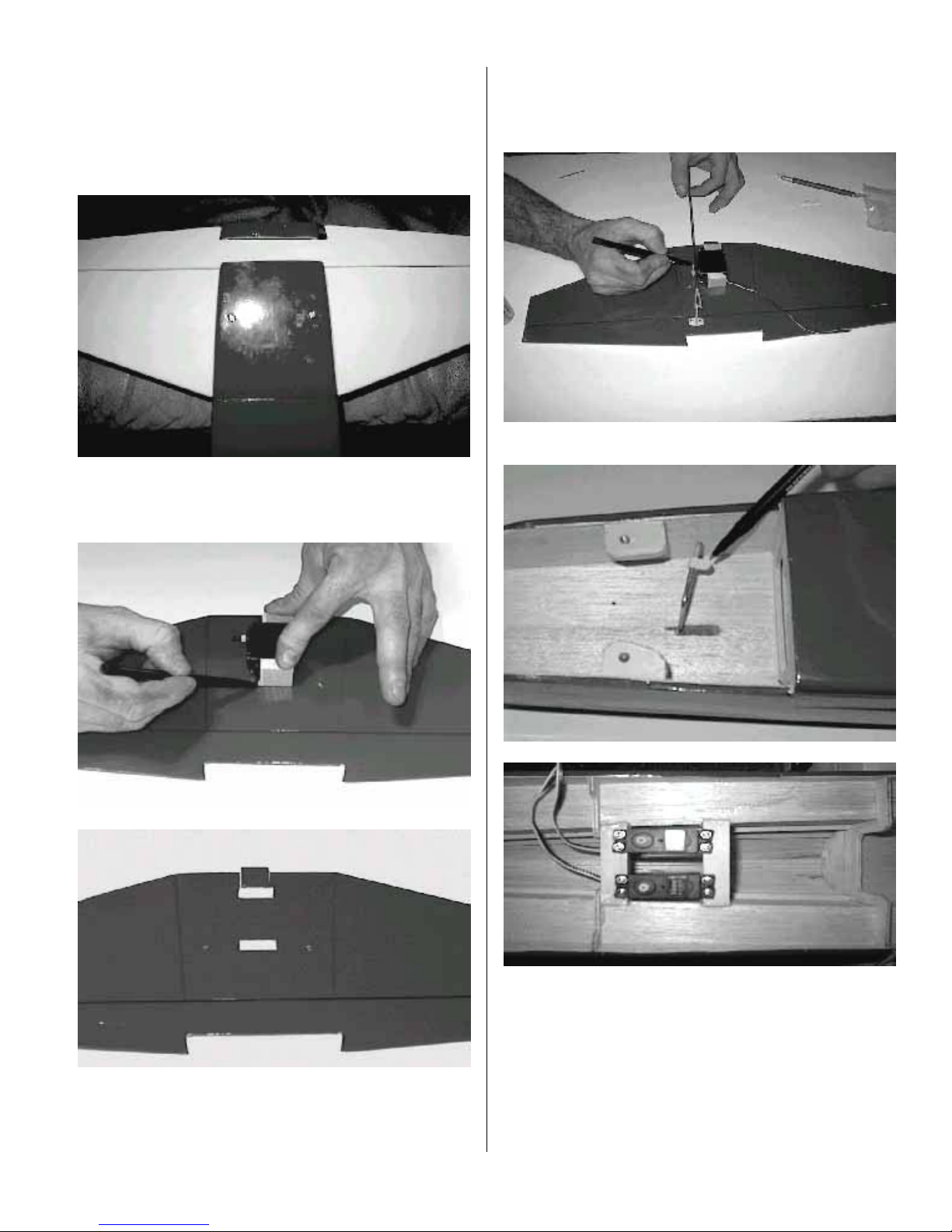

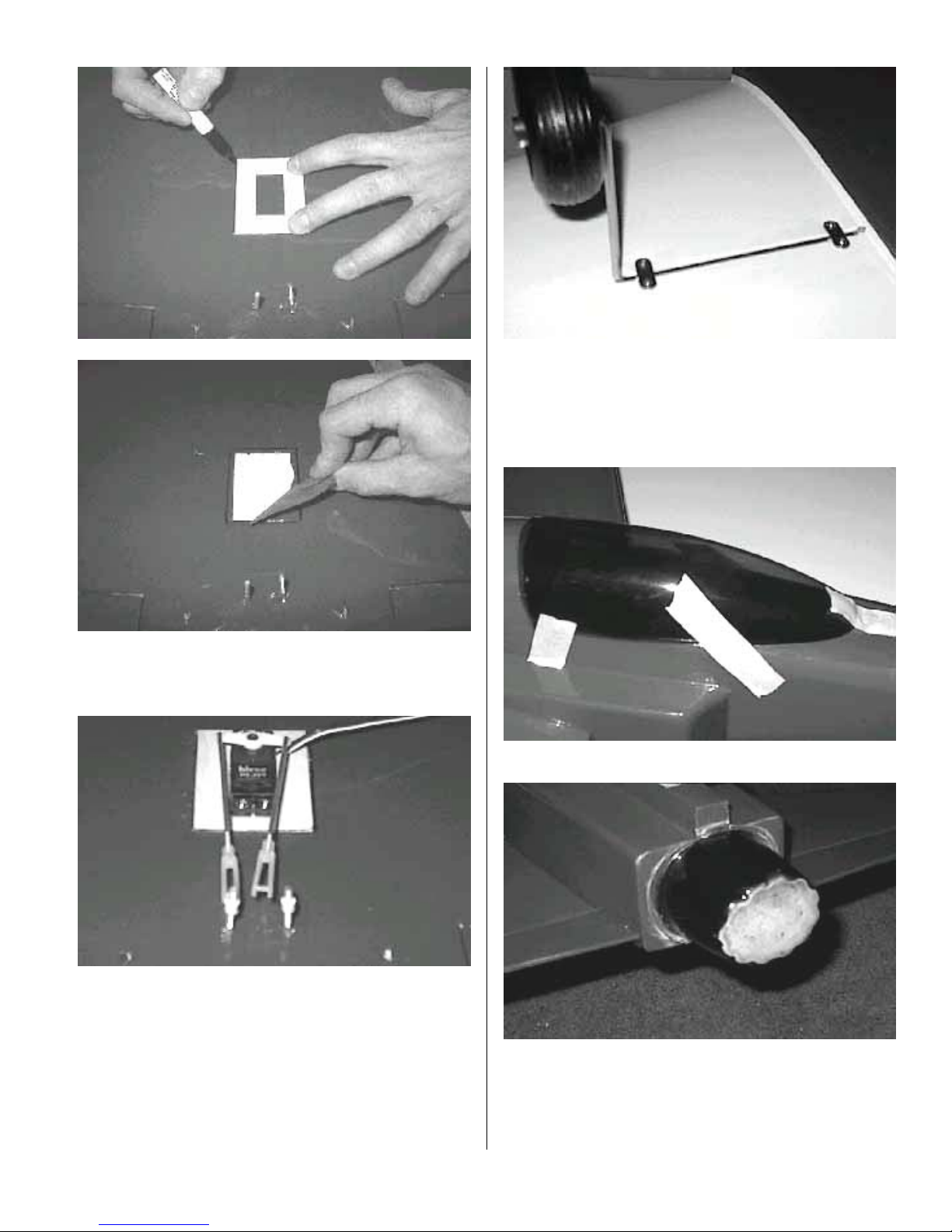

With your radio on, center all trims and adjust the

clevises so all control surfaces are straight. Measure

the control surface movement at the widest part of

each surface. Use the servo horns and bell crank

holes to adjust the control throw. For your first

flights the control throws should be set to the

following:

Elevator 1/2-inch up / down

Rudder 1 ½- inch right / left

Aileron 1/4-inch up / down

MOTOR SET UP

Be sure the motor is properly broken in using the

manufacture instructions. Set the throttle throw to

shut the motor off when the trim is pulled down and

idles reliably with the trim up.

After the motor is set, run one tank of gas at full

throttle, measure how much time it takes to run the

tank dry.

CONGRADULATIONS you are now ready for test

flights.

Before leaving for the field be sure your batteries

are fully charged and you have all the required

support equipment {fuel, starter, glow driver, etc.}.

Although the TIGER SHARK will fly well in wind,

wait for a nice day.

At the field have a helper hold the airplane,

following the radio manufactures instructions

perform a range check of the radio. Do this with the

motor off, start the motor and do it again. Perform

this test EVERY TIME YOU GO TO FLY!

TRIMING BASIC FLIGHT

The TIGER SHARK is NOT a trainer. A true

aerobatic aircraft, it goes only where you point it

and will not recover to level flight without control

input. If you do not have high performance

experience seek the help of someone who does.

Line up on the center of the runway and slowly

open the throttle, using the rudder to maintain

directional control. Once the tail is up apply a little

up elevator and allow the plane to gently lift off the

runway. Keep the climb angle and turns shallow

10