Elevator 1-inch up / down

Rudder 1 3/4- inch right / left

Aileron 1/2-inch up / down

Double check all controls move in the proper

direction.

MOTOR SET UP

Be sure the motor is properly broken in using the

manufacture instructions. Set the throttle throw to

shut the motor off when the trim is pulled down

and idles reliably with the trim up.

After the motor is set, run one tank of gas at full

throttle, measure how much time it takes to run

the tank dry.

CONGRADULATIONS you are now ready

for test flights.

Before leaving for the field be sure your batteries

are fully charged and you have all the required

support equipment {fuel, starter, transmitter,

ect.}.

Although the LASER 2000 will fly well in wind,

wait for a nice day.

At the field have a helper hold the airplane,

following the radio manufactures instructions

perform a range check of the radio. Do this with

the motor off, start the motor and do it again.

Perform this test EVERY TIME YOU GO TO

FLY!

TRIMING BASIC FLIGHT

The LASER 2000 is NOT a trainer. A true

aerobatic aircraft, it goes only where you

point it and will not recover to level flight

without control input. If you do not have

high performance experience seek the

help of someone who does.

Line up on the center of the runway and slowly

open the throttle, using the rudder to maintain

directional control. Once the tail is up apply a

little up elevator and allow the plane to gently lift

off the runway. Keep the climb angle and turns

shallow until you reach a safe altitude. Reduce

the throttle to about 60% power. With the

airplane flying away from you adjust the radio

aileron trim tab till the wing stays level. Turn and

line up the plane with the runway. Adjust the

elevator trim till the plane maintains level flight.

Once again with the airplane flying away from

you adjust the rudder trim till the fuselage tracks

straight {it may be necessary to correct the

aileron trim after this procedure}. Continue to fly

and trim until the aircraft is tracking well, land

before the fuel runs out. Carry a little power on

final approach until over the end of the runway,

then cut power to idle, hold the plane just off the

runway till the airspeed bleeds off and the plane

settles on. If the landing is too long add power go

around and try again, don’t try to force it to the

ground.

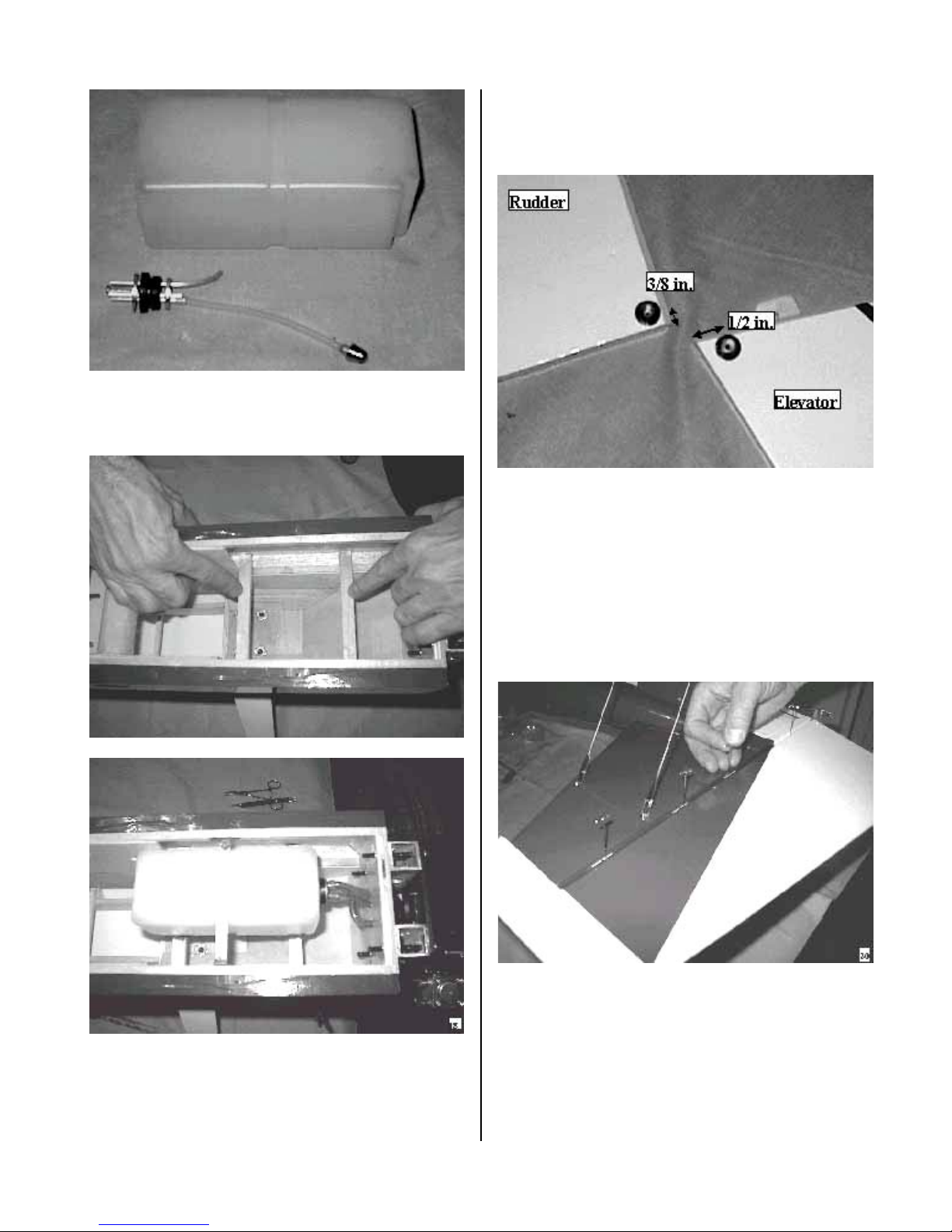

Now its time to zero out the trims. To do this

measure the control location, center the trim tab

on the radio and adjust the servo horn for large

changes, the control clevis for small changes. For

example if after the flight the rudder is 3/16 inch

to the right, center the radio trim and adjust the

clevis till the rudder once again measures 3/16

right. By doing this whenever you fly, setting the

radio trims at center will result in a well-trimmed

plane. Increase the control travel, as you become

more familiar with the flight characteristics until

loops take about 50 feet and knife edge can be

maintained with 80% stick deflection. Final roll

rate should be 300-360 degrees per second.

If you have followed the procedures in

this Manuel you will now be rewarded

with one of the finest flying sport models

available. All primary aerobatic

maneuvers are at your fingertips and the

aircraft will perform them with ease. No

further trim work will be required until you

are ready for unlimited and advanced 3-D

flight. Before attempting any of the

ADVANCED FLIGHT TRIM procedures you

must be completely comfortable with

inverted and knife-edge flight. The

following trim sequence is very time

consuming and you may not be able to

complete it in one day. Every change

made during this procedure will affect all

others so it will be necessary to start the

procedure from the beginning after each

adjustment.