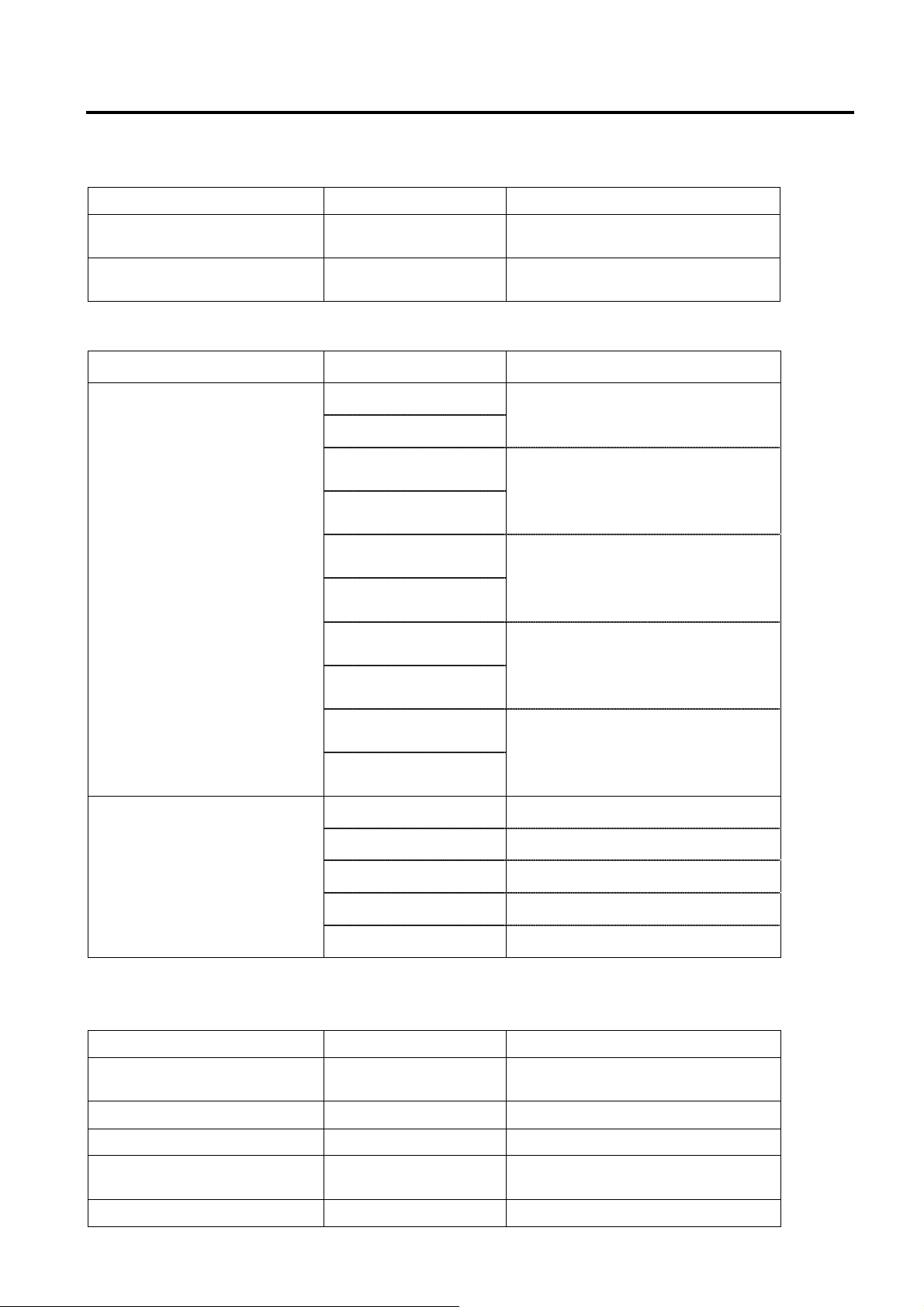

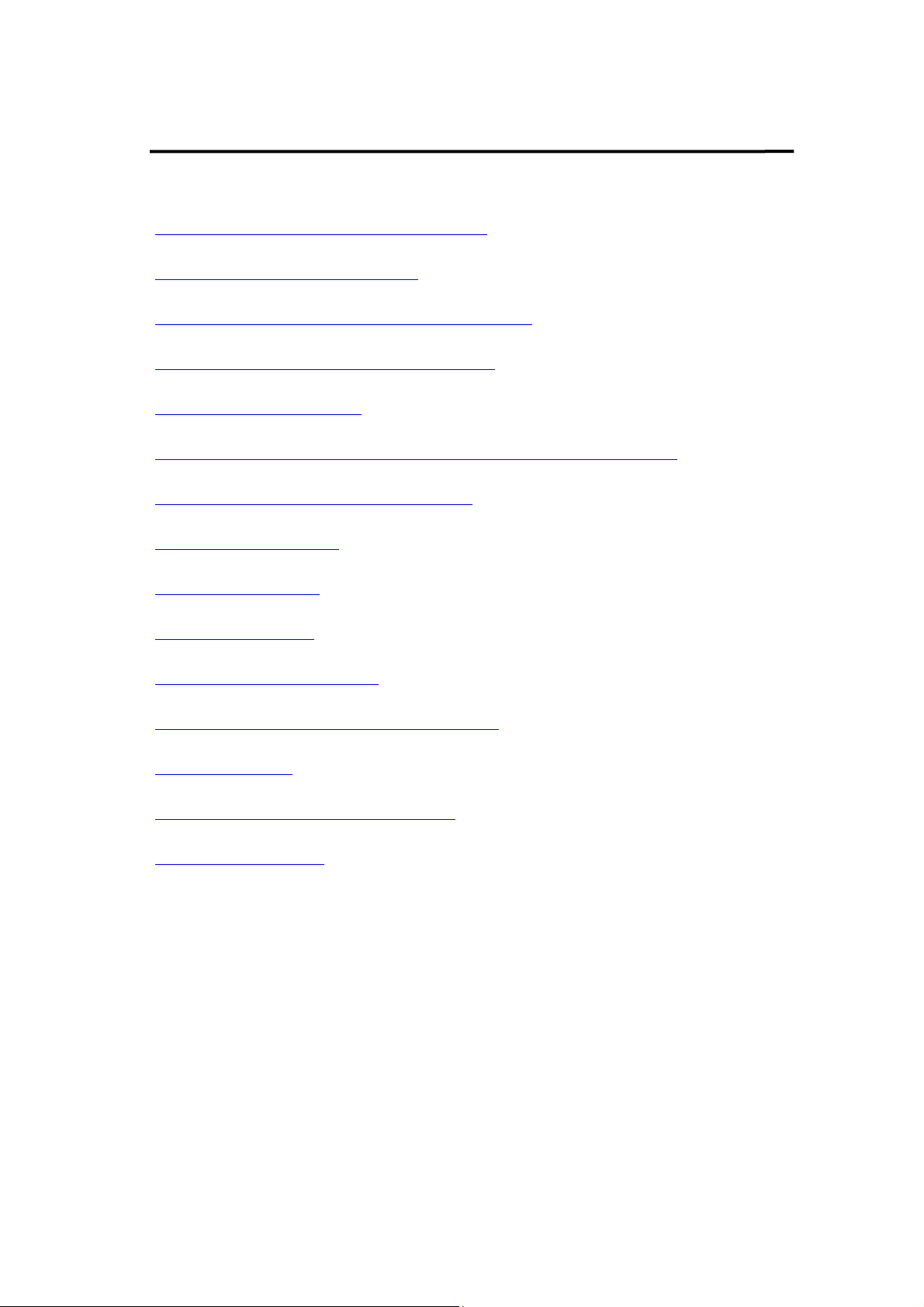

Table of Contents

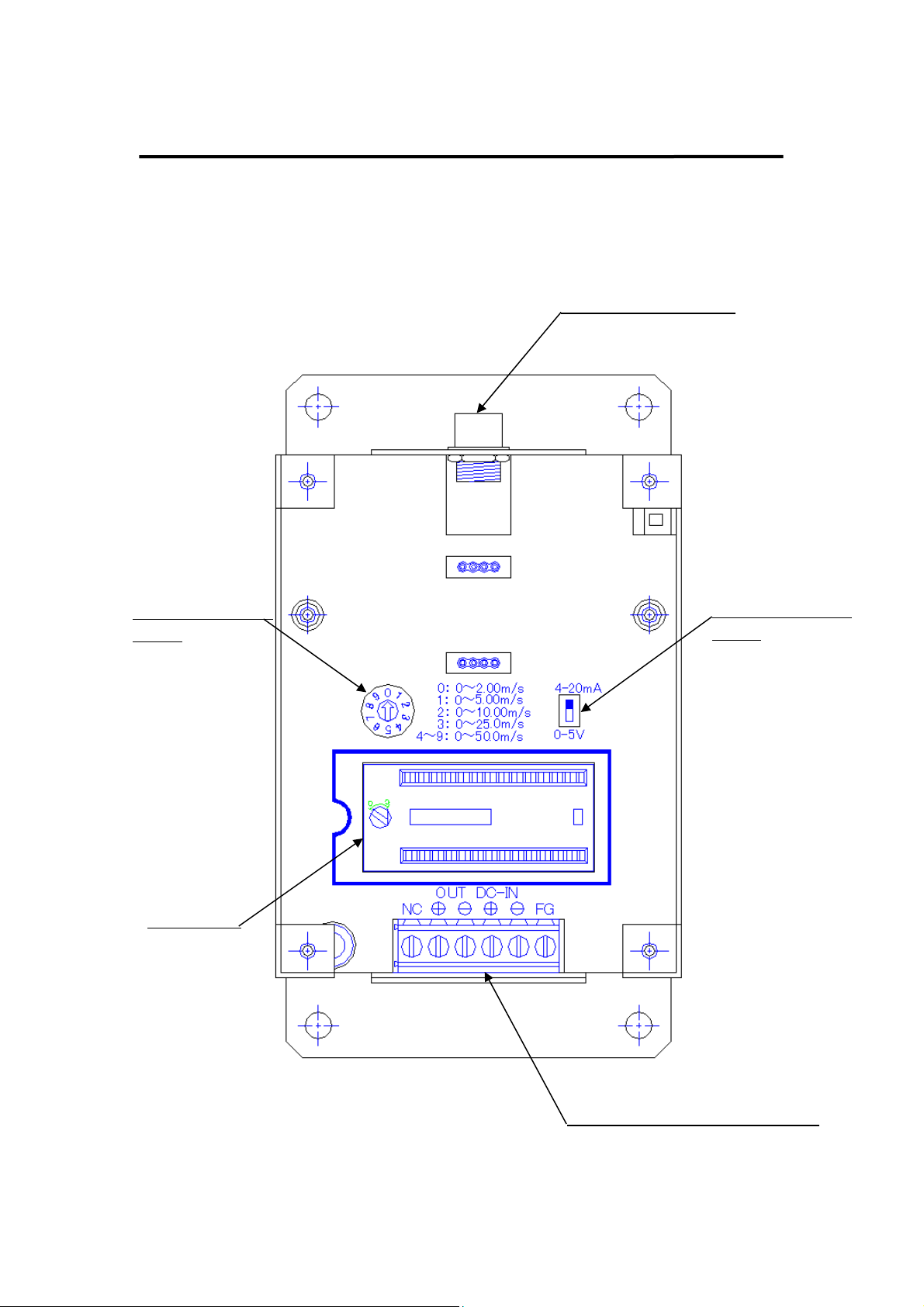

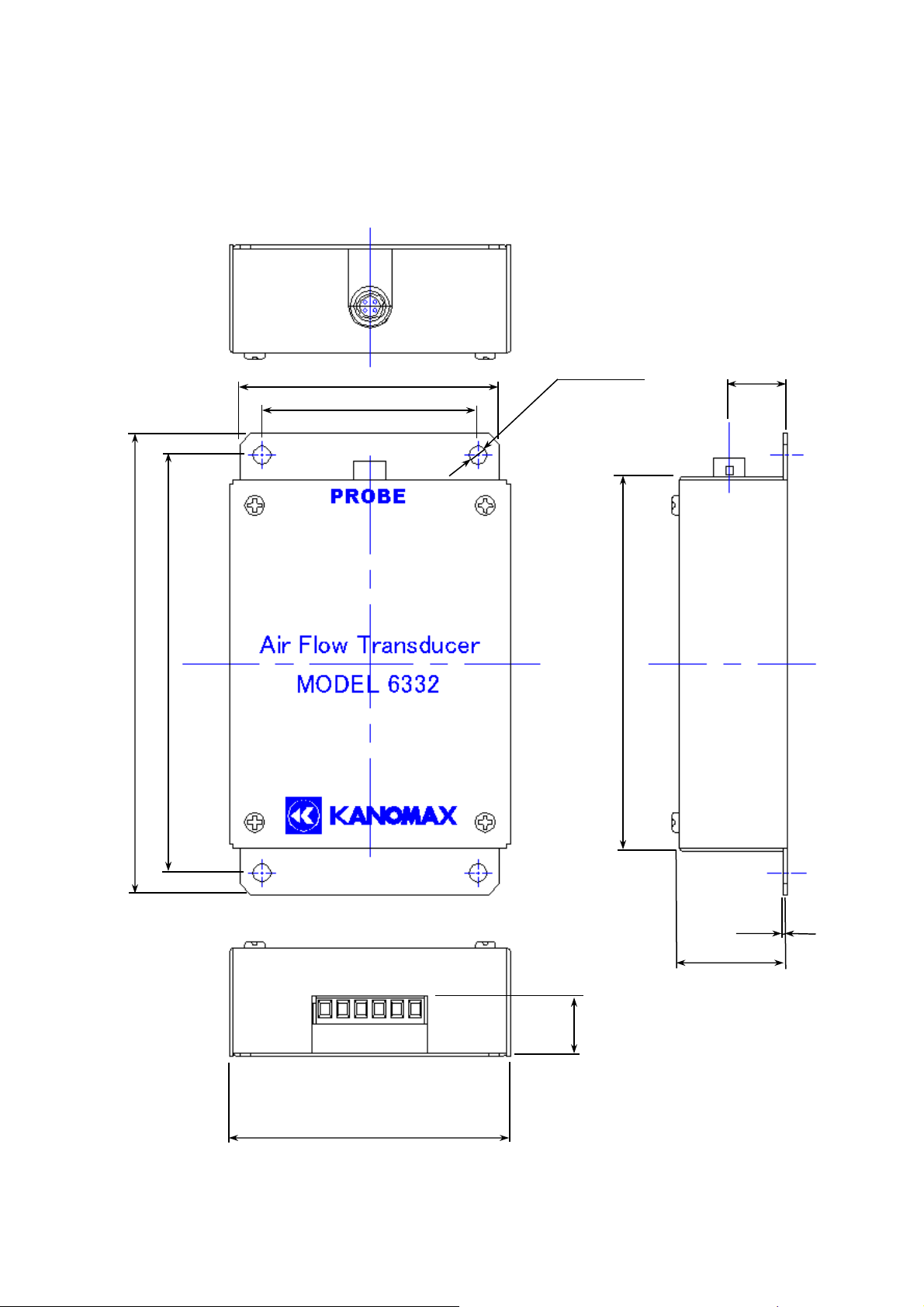

Names and Dimensions of Components........................................................ 1

System Configuration Example ..................................................................... 5

Connecting the Probe Cable to the Main Unit............................................... 6

Connecting the Probe Cable to the Probe ...................................................... 6

Installing the Data ROM................................................................................. 7

Switching Output (Setting Current/Voltage and Output Range).................. 8

Connecting Output and Power Supply......................................................... 10

Measurement Method................................................................................... 11

Optional Accessory....................................................................................... 12

Cleaning the Probe........................................................................................ 13

Specification of Main Unit ........................................................................... 14

Specification of Probes (Sold Separately) ................................................... 15

Troubleshooting ............................................................................................ 17

Product Warranty and After Service............................................................ 18

Contact Information...................................................................................... 19