vii

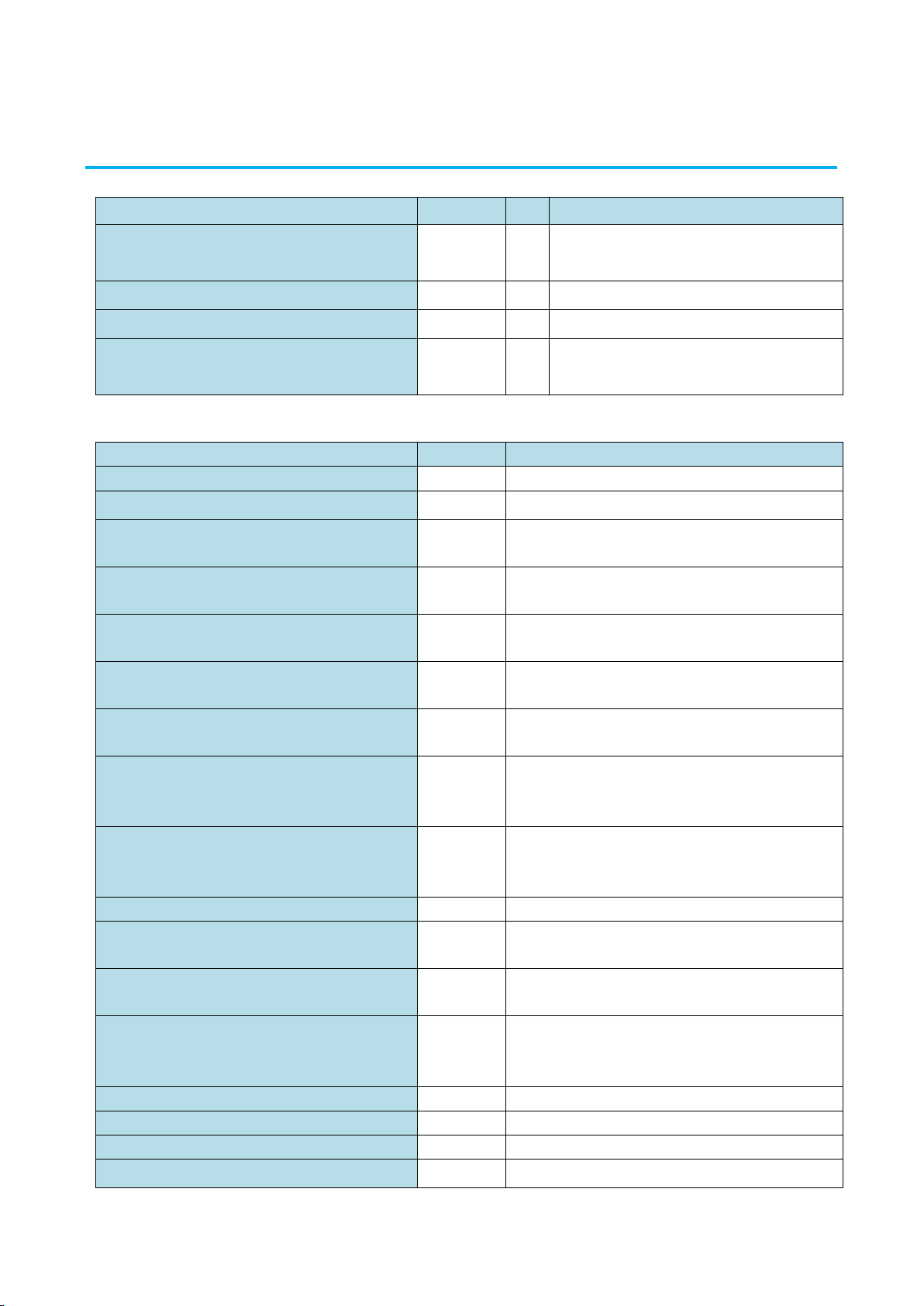

Table of Contents

List of Components ................................................................................................................................. i

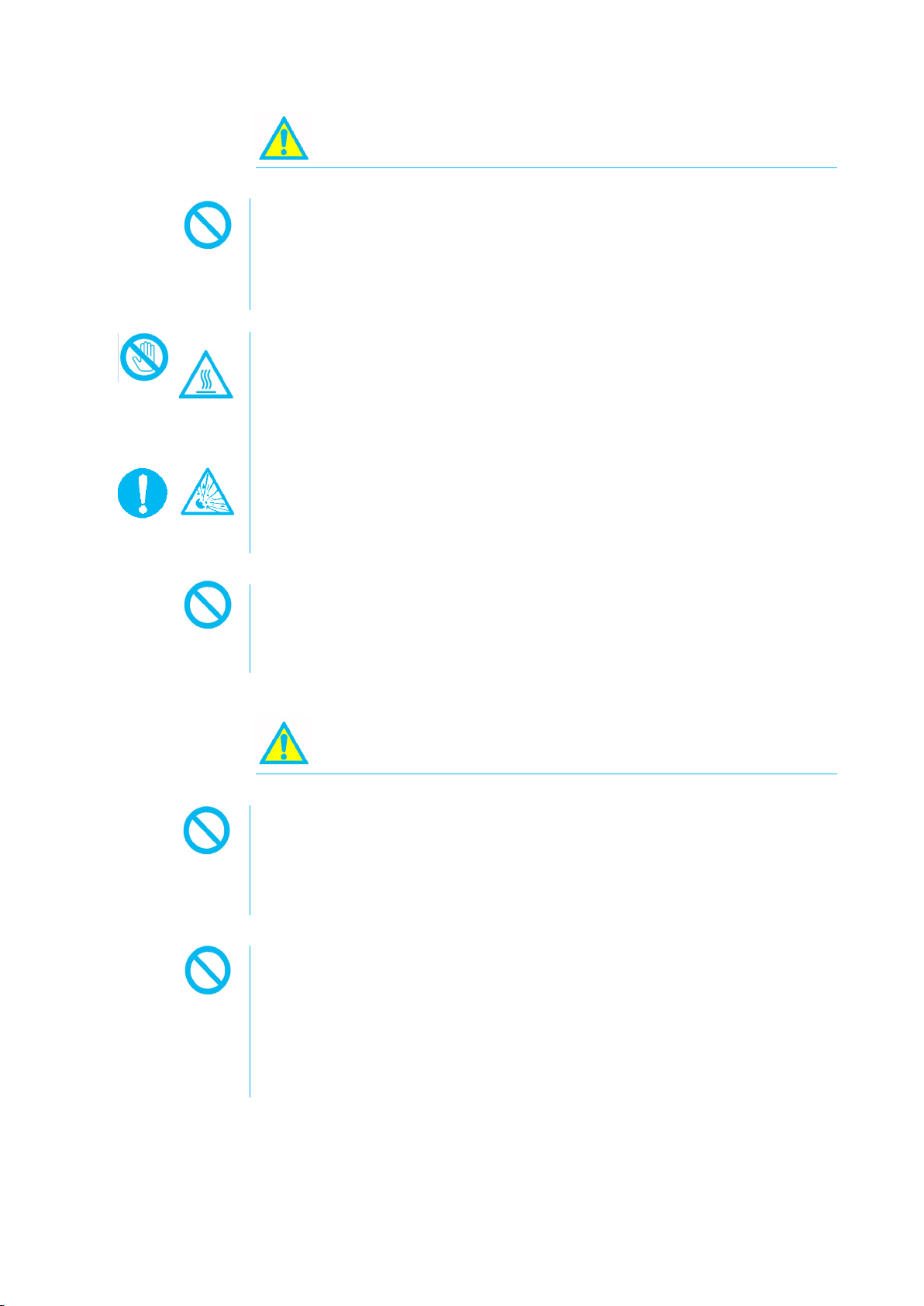

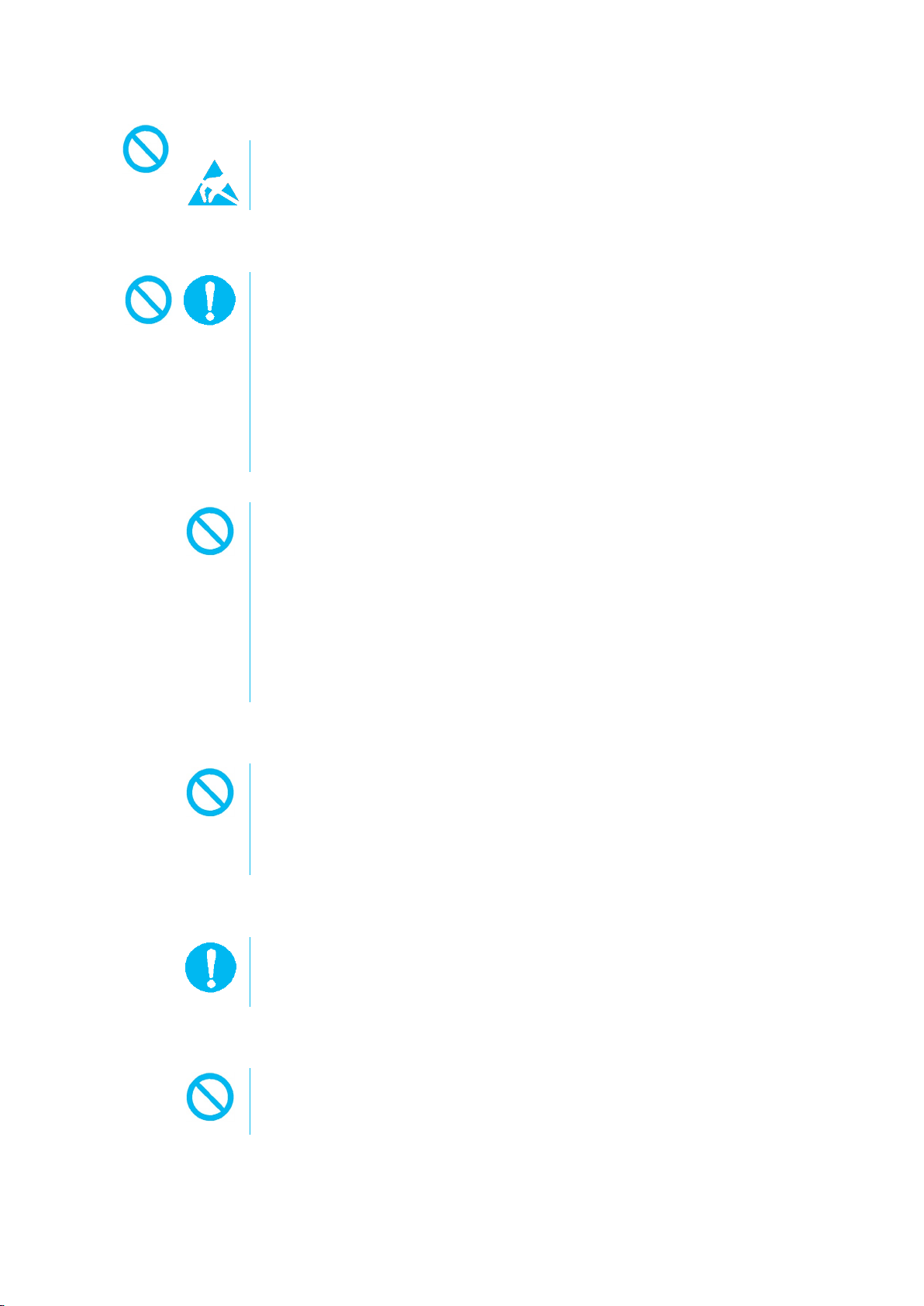

Important Safety Information............................................................................................................ iii

Table of Contents.................................................................................................................................. vii

1. Product Appearance .......................................................................................................................... 8

1-1.Part Names and Functions

............................................................................................................... 8

1-2.External Dimension

........................................................................................................................... 9

1-3. Mounting/Removing DIN Rail Fixing Base

.................................................................................... 10

2. How to Use ........................................................................................................................................ 11

2-1.Basic Usage

...................................................................................................................................... 11

2-2.Mounting/Removing the Probe

..................................................................................................... 12

2-3.Connecting the Cable to the Terminal Block

............................................................................... 13

2-4.Connecting Power Source

.............................................................................................................. 14

2-5.Connecting Analog Output

............................................................................................................. 15

2-6.Connecting the Communication Connector

................................................................................. 16

2-7.Connecting the Probe Fixing Jig (accessory)

.............................................................................. 17

3. Various Settings ............................................................................................................................... 19

3-1.Displayed Unit Setting

.................................................................................................................... 19

3-2.Air Velocity Analog Output Setting

............................................................................................... 20

3-3.Air Temperature Analog Output Setting

...................................................................................... 21

3-4.Humidity Analog Output Setting

................................................................................................... 22

4. Specifications.................................................................................................................................... 23

5. Probe/Standard Cable (Option) Specifications ......................................................................... 24

5-1.Probe Specifications

........................................................................................................................ 24

5-2.Standard Cable Specifications

....................................................................................................... 28

6. Troubleshooting ............................................................................................................................... 29

Probe Cleaning....................................................................................................................................... 30

7. Warranty and After-Sales Services.............................................................................................. 32

8. Contact Information........................................................................................................................ 33