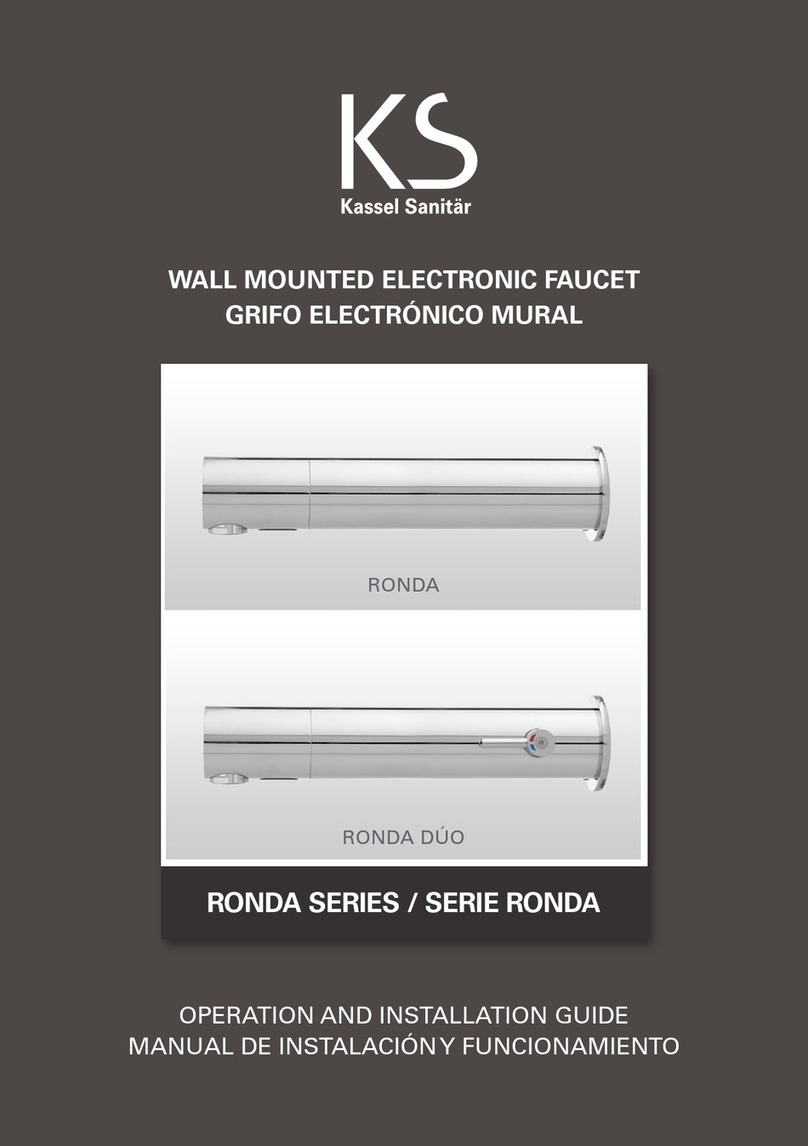

11

10

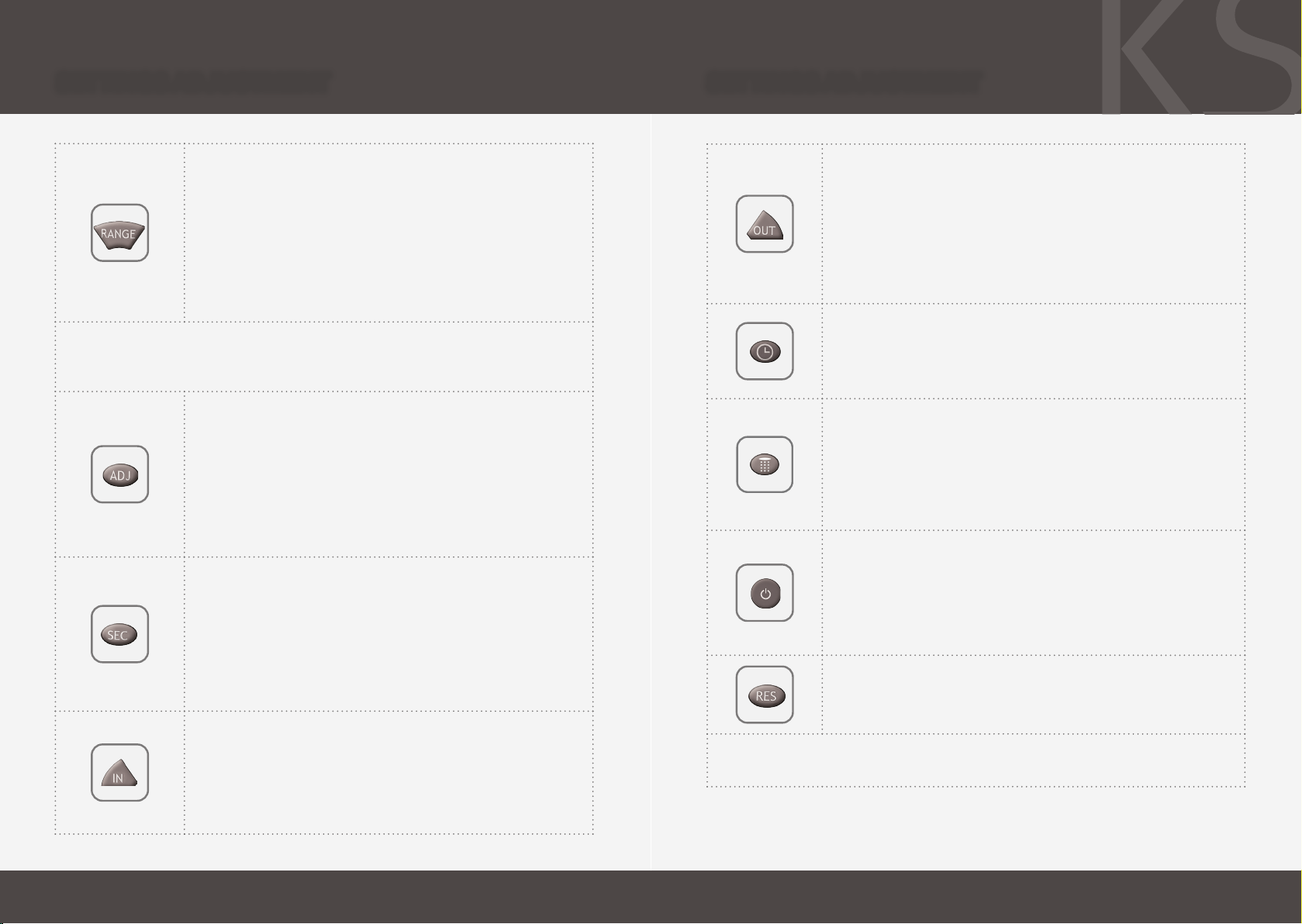

SETTINGS ADJUSTMENTSETTINGS ADJUSTMENT

DETECTION RANGE: This faucet was supplied with a self

adjusting sensor.The ideal detection range for the specific

location will be set automatically.

Only if necessary, use the remote control to adjust the sensor

range as follows:

Press the RANGE button. Wait until a quick flashing of the LED

in the sensor eye is perceived.Then, press + to increase the

range and – to reduce it. Every push will increase or decrease

one level.

Note: Once you have changed the detection range with the remote control,

the distance will be remembered by the sensor, even if the power source is

disconnected.To get back to the self adjustment mode, use the ADJ button only.

ENTRANCETOTHE SELF ADJUSTMENT MODE: Check that no

objects are in front of the sensor. Press the ADJ button. Once

a quick flashing of the LED of the sensor eye is perceived,

remove your hand holding the remote control and move away

from the sensor area.The ideal sensor range for the specific

location will be set automatically. Once the self adjustment has

taken place, the solenoid valve will be opened and closed for 1

second as an indication that the ideal sensor range was set and

the product is ready for use.

SECURITYTIME:The Security time, prevents continuous

running of water due to reflections or vandalism. By default,

if the sensor is covered for more than 90 seconds the water

flow will shut automatically.To resume regular operation any

obstruction must be removed.

Press the SEC button. Wait until a quick flashing of the LED

in the sensor eye is perceived.Then, press + to increase the

security time and – to reduce it.

DELAY INTIME: It is recommended to change the delay in

time for flush valves for urinals or toilets only.

If required, the delay in time can also be modified in faucets

as follows:

Press the IN button. Wait until a quick flashing of the LED in

the sensor eye is perceived.Then, press + to increase the

delay in time and – to reduce it.

DELAY OUTTIME:This button allows modifying the water

flow time after the user removes his hands from the

faucet. A delay out time close to 0 will save more water.

An increased delay out time will make the user experience

more comfortable.

If required, the delay out time can be modified as follows:

Press the OUT button. Wait until a quick flashing of the LED

in the sensor eye is perceived.Then, press + to increase the

delay out time and – to reduce it.

24 HOUR HYGIENE FLUSH:This model includes a 24 hours

hygiene flush which is disabled.To activate the hygiene flush,

press the clock button. Wait until a quick flashing of the LED

in the sensor eye is perceived.Then press + to activate the

hygiene flush.To disable it again, press – to deactivate it.

COMFORT FLUSH: If your model includes a Comfort flush

setting, it can be activated by pressing the flush button.

When the button is pressed, one blink of the LED in the

sensor eye is perceived.The pre-programmed flush cycle will

take place then.

The Comfort flush cannot be interrupted or deactivated by

pressing any button until it is over.

TEMPORARY OFF FUNCTION:This function is ideal to

perform any kind of activity in front of the sensor without

operating the system (for example, cleaning).

The faucet will remain shut for 1 minute when this button

is pressed once.To cancel this function and to return to

normal operation press the On/Off button again or wait 1

minute.

RESET BUTTON:This function restores all the factory

settings except for the sensor range. If required, press the

Reset button and without releasing it, press the + button

once.

NOTE: To enter the self adjusting mode, use the ADJ button.To change the

sensor range, use the RANGE button.