Original Operating Manual

Contents Page

1. Introduction ............................................................................................................................................. 4

1.1 Working with this manual......................................................................................................... 4

1.2 Warning notes and symbols..................................................................................................... 4

1.3 Copyright.................................................................................................................................. 4

1.4 CE-Mark................................................................................................................................... 5

1.5 Qualified and authorised personnel ......................................................................................... 5

1.6 Warranty claims based on defects........................................................................................... 5

1.7 Limits of applicable use............................................................................................................ 5

2. Safety aspects......................................................................................................................................... 6

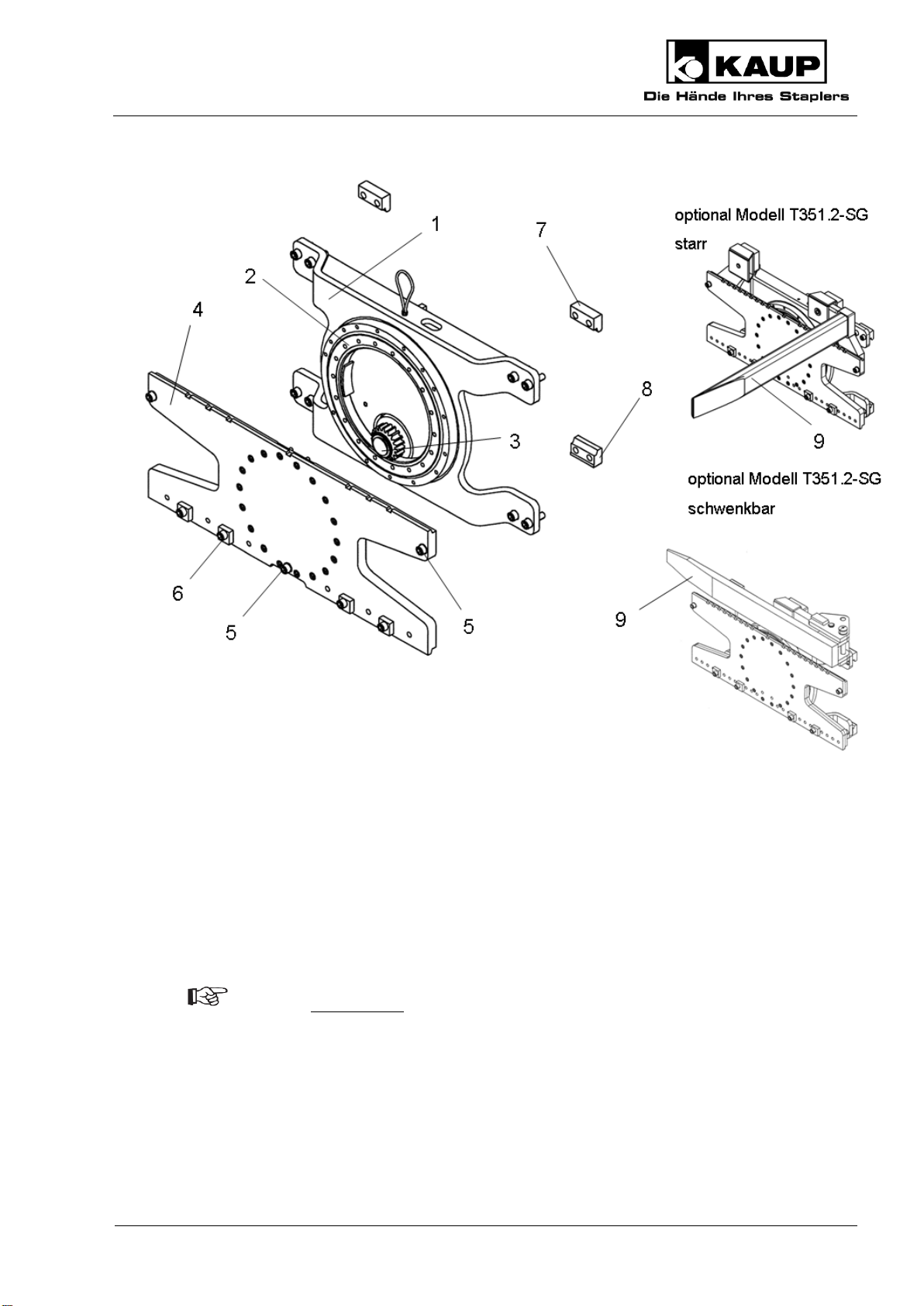

3. Design ...................................................................................................................................................... 7

3.1 Efficient equipment settings on electric vehicles ..................................................................... 7

3.2 Proper use of the equipment.................................................................................................... 7

3.3 Improper use............................................................................................................................ 8

3.4 Hydraulic oil flow required........................................................................................................ 8

4. Installation and checking out ................................................................................................................ 9

4.1 Installation................................................................................................................................ 9

4.1.1 Model T351.2 ............................................................................................................... 9

4.1.2 Fork carriage.............................................................................................................. 10

4.2 Installing the support fork (fixed)............................................................................................ 11

4.3 Installing / swivelling the support fork (swivelling) ................................................................. 12

4.4 Checking out .......................................................................................................................... 13

4.4.1 Bleeding the hydraulic system................................................................................... 13

4.4.2 Adjustment after putting into service.......................................................................... 13

5. Operation ............................................................................................................................................... 13

5.1 General................................................................................................................................... 13

5.2 Load handling......................................................................................................................... 14

5.3 Driving.................................................................................................................................... 14

5.4 Rotate..................................................................................................................................... 14