1

KS1000 Assembly-and operating instructions

1. Summary

1Instruction of this manual--------------------------------------------------------------------3

1.1Product Description---------------------------------------------------------------------------3

1.2Application area--------------------------------------------------------------------------------5

1.3Technical parameters--------------------------------------------------------------------------5

1.4Security----------------------------------------------------------------------------------------- 5

2. Basic Assembly

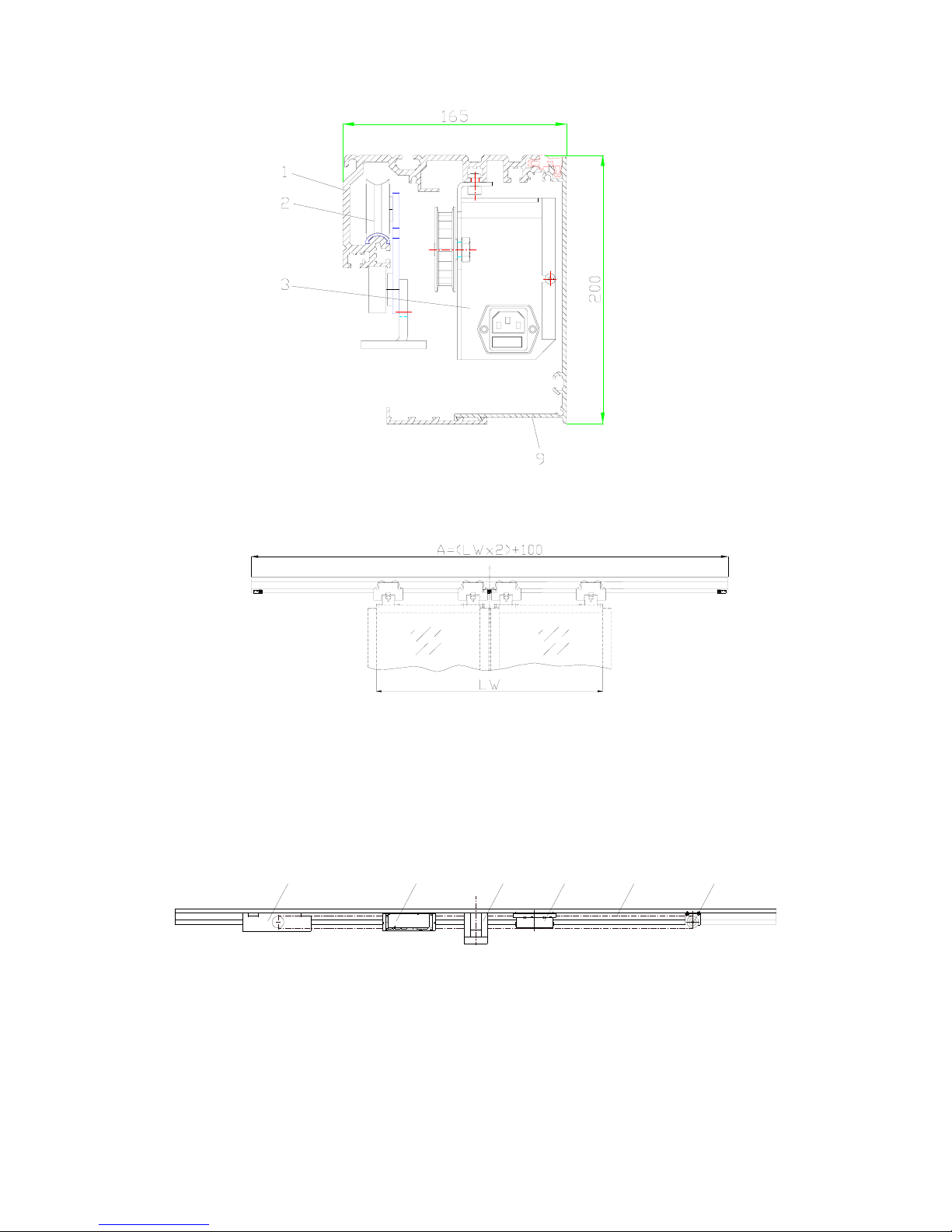

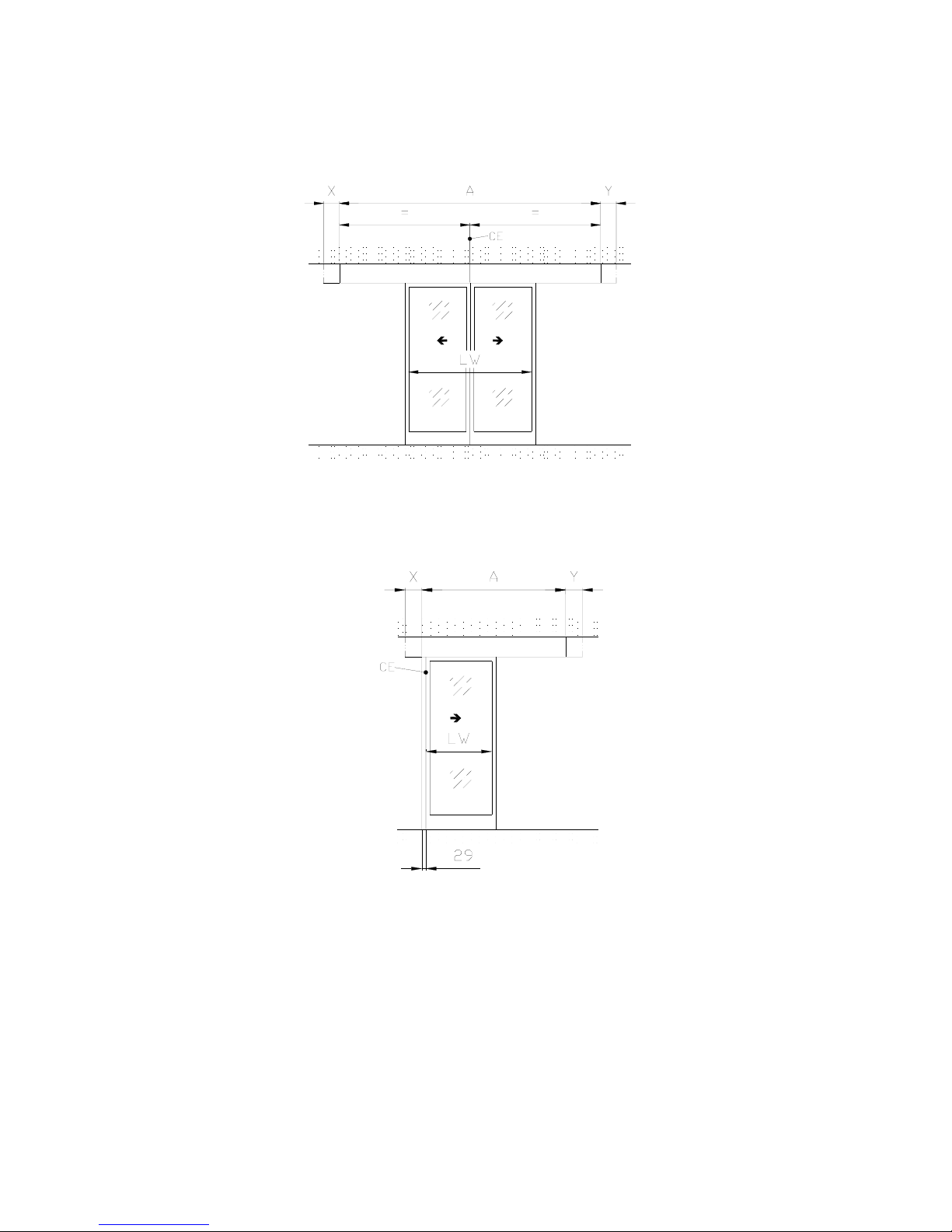

2.1 Assembly types ----------------------------------------------------------------------------------- 6

2.2.Assembly instruction -----------------------------------------------------------------------------7

3. Components Installation

3.1 Installation of running carriage subassembly --------------------------------------------- 11

3.2 Installation of drive Unit--------------------------------------------------------------------- 14

3.3 Installation of reverse wheels---------------------------------------------------------------- 14

3.4 Installation of toothed belt----------------------------------------------------------------- 15

3.5 Installation of control unit-------------------------------------------------------------------- 16

3.6 Installation of control elements--------------------------------------------------------------16

4. Adjustment

4.1 Preparation before operation------------------------------------------------------------------17

4.2 Electrical settings-------------------------------------------------------------------------------17

4.3 System start-up----------------------------------------------------------------------------------18

4.4 Interruption of self-inspection-----------------------------------------------------------------18

Functions of operating device

5.1 General--------------------------------------------------------------------------------------------19

5.2 PSA controller(Option)---------------------------------------------------------------------19

5.2.1 Operating Functions(1st level)---------------------------------------------------19

5.2.2 Setting functions(2nd level)------------------------------------------------------ 20

5.2.3 Programming function(3rd level)----------------------------------------------------21

5.2.4 problem indication(4th level)-----------------------------------------------------26

5.3Security Device--------------------------------------------------------------------------------29

5.4Main input & output terminal functions----------------------------------------------------29

5.5Interlock functions-----------------------------------------------------------------------------30

5.6Attention details--------------------------------------------------------------------------------31

3

3

5

5

5

6

7

11

14

14

15

16

16

17

17

18

18

19

19

19

20

21

26

29

29

30

31