IMPORTANT: To reduce the risk of fire, bodily injury, and damage to the

equipment, read through Instruction Manual before operating ESC and

always follow all instructions.

KEEP OUT OF THE REACH OF CHILDREN.

Pay attention to the maximum voltage allowed:

KDE-UAS LV Series 7.4V (2S LiPo) –26.1V (6S LiHV) 26.5V Max.

KDE-UAS XF Series 7.4V (2S LiPo) –34.8V (8S LiHV) 35V Max.

KDE-UAS HVC Series 11.1V (3S LiPo) –52.2V (12S LiHV) 55V Max.

If model is not listed, maximum voltage is stated in specifications.

Operating outside of the listed voltage voids warranty.

All KDE Direct ESCs are opto-isolated and do not provide BEC power output for

the peripheral equipment and requires 3 to 12V applied to the control lead.

Never operate the ESC beyond the specifications stated on hardware. Serious

injury or property damage can result from misuse.

Ensure the polarity is correct with the power supply to the ESC power source

leads. Reverse polarity may cause fire and serious injury and will immediately

damage the ESC beyond warranty coverage.

Ensure the ESC is installed in a safe location and protected to prevent any

exposed connections and solder-locations from contacting conductive areas.

Always use electronics-grade solder and make sure to use proper soldering

techniques and equipment. Poor soldering technique is a common cause of in-

flight failure and ESC damage. Ensure all connectors are protected with

insulation and heat-shrink to prevent unwanted conduction and shorts.

Check all connectors for secure connection before flight. Disconnection due to

vibration and flight-conditions can result in a dangerous loss of control and

potential damage and serious injury.

Do not disassemble or open the ESC or DMA. Opening of the case or removal of

shrink-wrap may cause damage to the internal components, void all warranty

claims, and yield unsafe operation.

Install the ESC in a location with adequate airflow to maintain cool

temperatures and achieve the maximum performance rating.

An electric motor that is connected to the ESC can start unexpectedly and can

cause serious injuries. Always remove the propeller and disengage all gearing

when working on the system with power applied.

Do not allow full submersion of the ESC in water. Water can damage the ESC

and cause malfunction and failure of the electrical components.

KDE Direct is not responsible for the use of this Product(s) or for any

damages or injuries caused or sustained by its usage. Always observe all

laws and instructions regarding the use of this Product(s), and operation of

devices using this Product(s).

This is a high-power, electromechanical device with the potential to be very

dangerous –always handle with caution and be aware of proper operation.

This product may contain chemicals known to the State of California to cause

cancer and/or birth defects or other reproductive harm. Do not ingest or

attempt to ingest this product.

Disconnect brushless motor from ESC motor leads before programming ESC.

An electric motor that is connected to the ESC can start unexpectedly and

cause serious injuries or damage.

Before flight, ensure that all ESCs are operating on the same settings and

firmware.

Extending the ESC power leads is at your own risk and voids the warranty.

At low load we recommend you turn off Synchronous Rectification, low load

may result in discontinuity with the motor RPM.

REVISION PR012

For the latest instruction manual revisions, software updates, liability

policy, and warranty information, visit the KDE Direct website at:

http://www.KDEDirect.com.

All technical inquiries, review the KDE Resource Center.

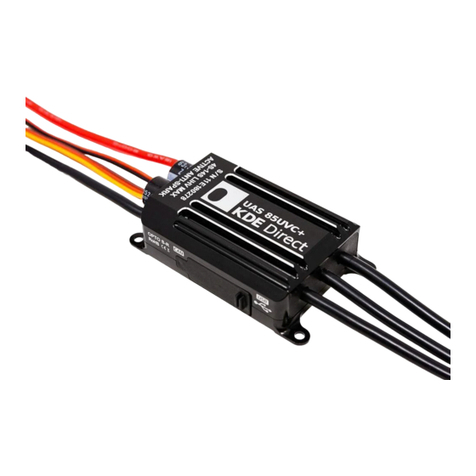

Pay close attention to proper wiring as shown in the diagram above. Ensure the

polarity is correct and proper soldering techniques are used when connecting

the power source and brushless motor to prevent damaging the ESC.

ESC INSTALLATION AND WIRING

(-) TO POWER SOURCE

(BLACK POWER LEAD)

TO FLIGHT CONTROLLER

(W-R-BLK CONTROL LEAD)

TO BRUSHLESS MOTOR

(BLACK MOTOR LEADS)

(+) TO POWER SOURCE

(RED POWER LEAD)

TO DEVICE MANAGER ADAPTER

(O-R-BRN PROGRAMMING LEAD)

1 2

The KDE Direct UAS ESC (Electronic Speed Controller) Series is specifically

designed for multi-rotor applications, and utilizes a proprietary algorithm

for up to 600Hz refresh rate communication and high-speed response for

optimal flight performance.