3

Operation Manual Supply Unit KeDrive D3-DP BG3 and BG4

ID no.: 1804.201B.0-00 Date: 08/2021

3.2 Mounting clearances ..........................................................................................17

3.3 Cooling the devices ............................................................................................18

3.4 Installation of the devices for wall mounting........................................................18

3.4.1 Dimensions, wall mounting model (housing with heat sink) ................19

3.5 Installation of devices for liquid cooling...............................................................20

3.5.1 Dimensions, liquid cooling model .......................................................21

3.6 Cooling circuit connection .................................................................................22

4 Electrical installation .............................................................. 23

4.1 Before you start .................................................................................................23

4.2 Effective EMC installation ..................................................................................23

4.3 Overview of the connections ..............................................................................25

4.3.1 PE connection according to DIN EN 61800-5-1 ..................................26

4.3.2 Connection principle ...........................................................................27

4.4 Electrical isolation concept.................................................................................27

4.5 AC mains connection (power supply) ................................................................29

4.5.1 Layout, X01A ......................................................................................29

4.5.2 Residual current device ......................................................................31

4.5.3 Mains fuses ........................................................................................32

4.6 Operation on TT, TN and IT system ...................................................................32

4.6.1 Operation of the KeDrive D3-DP supply unit on

TN and TT system ............................................................................32

4.6.2 Operation of the KeDrive D3-DP supply unit on IT system ................32

4.7 24 V control supply ............................................................................................33

4.7.1 Control supply with switched-mode power supply (in preparation) .....33

4.7.2 Control supply via external 24 V power supply unit ............................33

4.8 Busbars for the supply voltages .........................................................................36

4.8.1 DC link supply ....................................................................................36

4.8.2 Overview of busbars in the group........................................................37

Table of contents

1 General .................................................................................... 5

1.1 Target group .......................................................................................................5

1.2 Prerequisites.......................................................................................................5

1.3 Pictograms .........................................................................................................5

1.4 Disclaimer...........................................................................................................5

1.5 Reference documents ........................................................................................6

1.6 Order code .........................................................................................................6

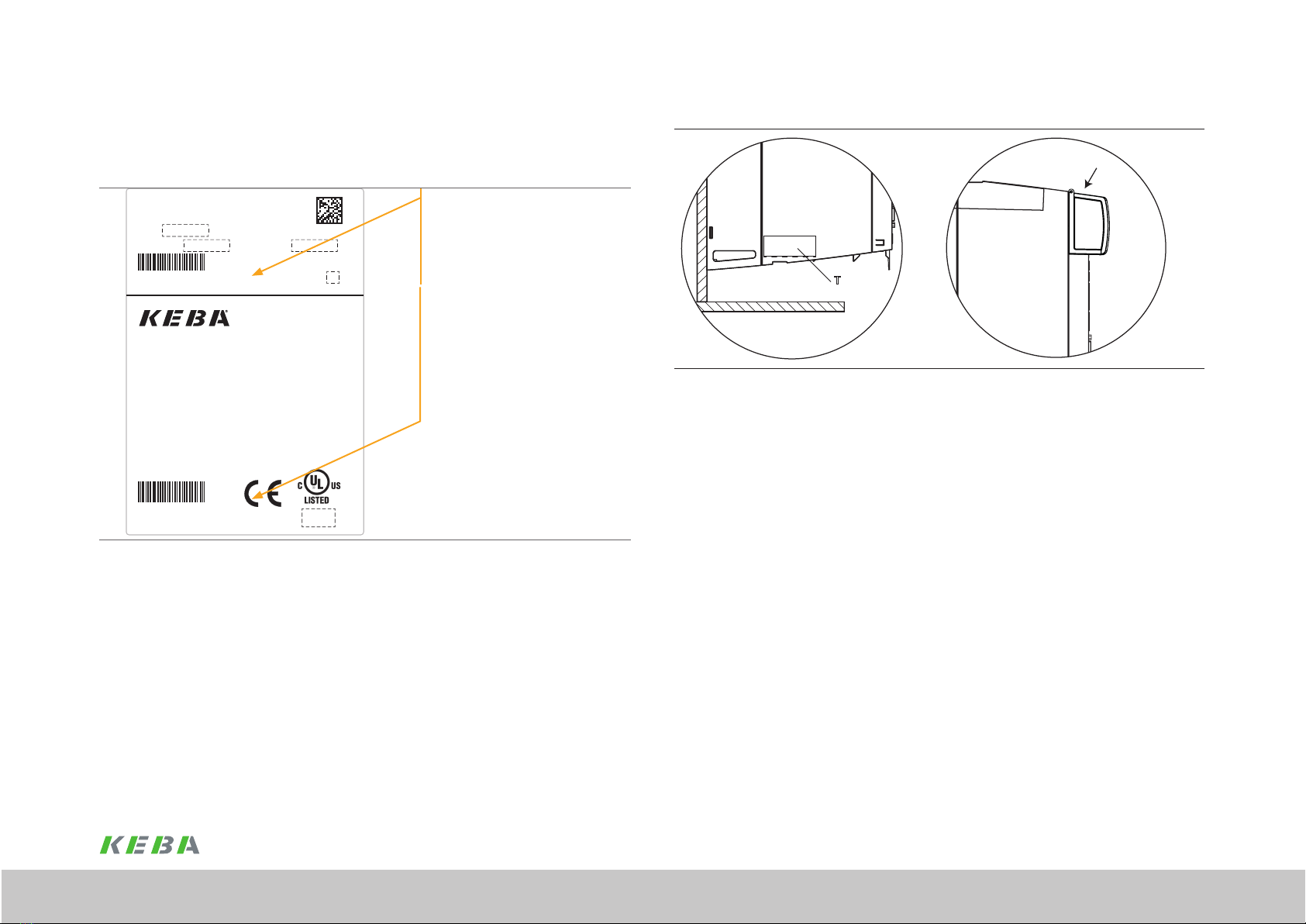

1.7 Rating plate .......................................................................................................7

1.8 Brief description ................................................................................................8

1.9 Scope of supply .................................................................................................8

1.10 Disposal .............................................................................................................8

1.11 S up po r t .............................................................................................................9

2 Safety .....................................................................................11

2.1 O v e r v i e w ............................................................................................................11

2.2 Measures for your safety ....................................................................................11

2.3 General safety instructions and warnings ...........................................................12

2.4 Intended use.......................................................................................................12

2.4.1 Repair..................................................................................................12

2.5 Misuse................................................................................................................13

2.6 Responsibility .....................................................................................................13

2.7 Relevant laws, standards and directives applied ...............................................13

2.8 Declaration of conformity ...................................................................................14

3 Mechanical installation ........................................................... 15

3.1 Notes for installation ...........................................................................................15

3.1.1 Order and arrangement.......................................................................15