Evolution3 FreeHand User Guide

The world’s finest cutting machines

www.keencut.com

+44 (0) 1536 263158

+1 (716) 748 6203

Scan the QR code or

click here to view this document online >

Page 2 of 43

Contents

1. Introduction 3 .........................................................................................................................................................

1.1 The Evolution3 FreeHand user guide 3 ........................................................................................................................

2. Get to know your cutter 4 .........................................................................................................................................

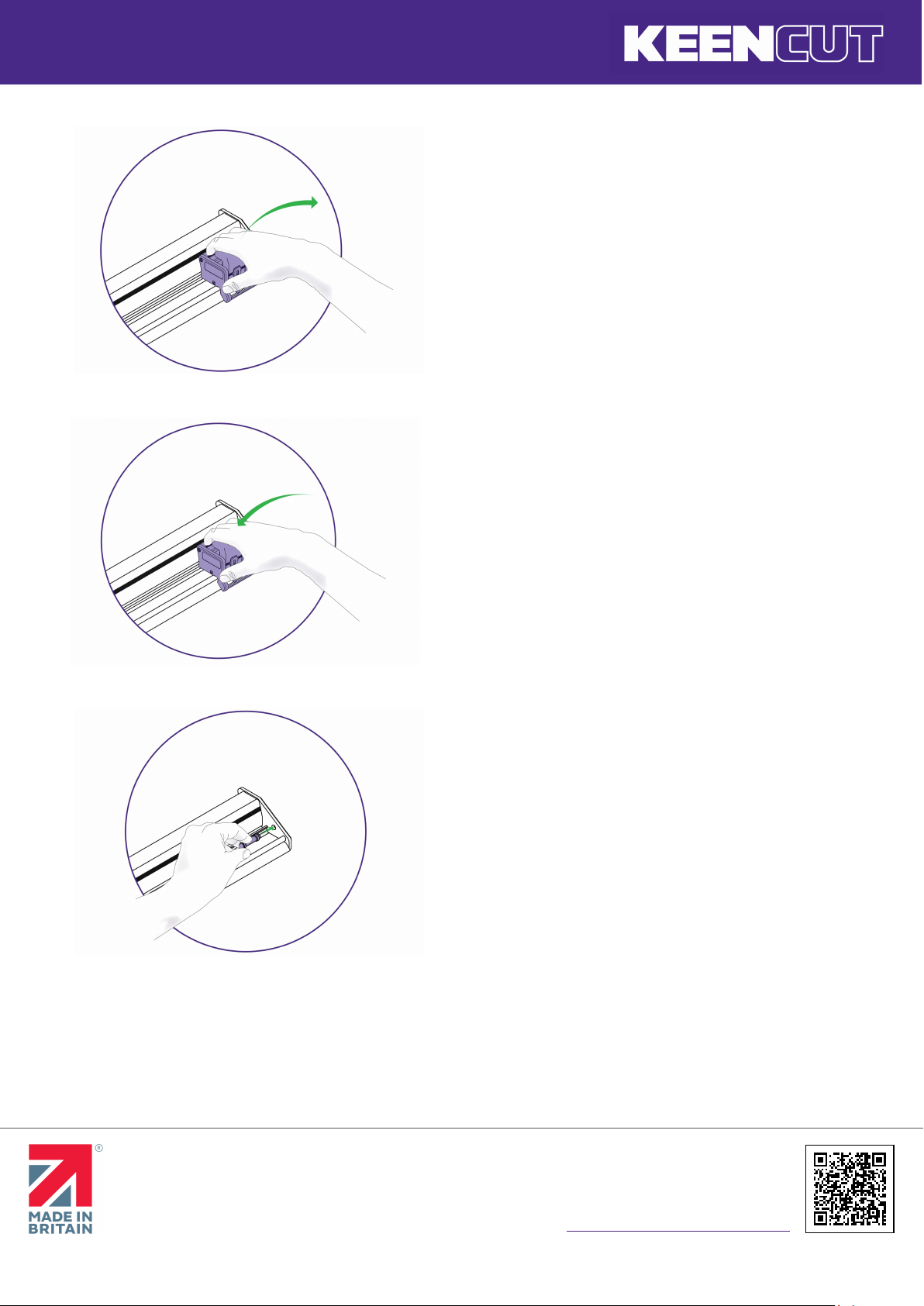

2.1 Swapping tool heads 4 ...........................................................................................................................................

3. Make your first cut 6 ................................................................................................................................................

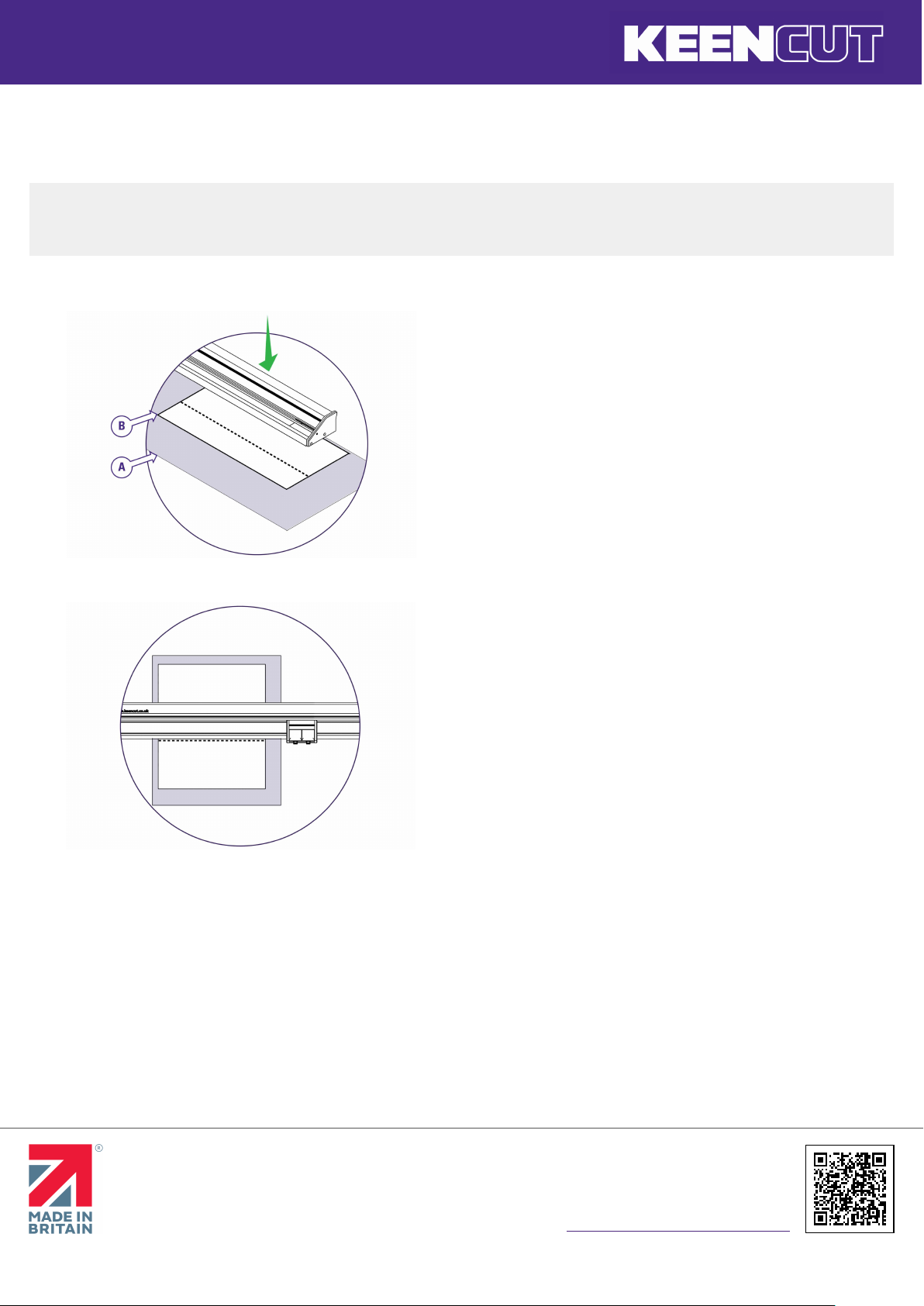

3.1 Align and clamp the material 6 .................................................................................................................................

3.2 Introduction to the Double Graphik tool head 7 .............................................................................................................

3.3 Insert Graphik blades into the Double Graphik tool head 8 ...............................................................................................

3.4 Double Graphik tool head cutting technique 10 .............................................................................................................

3.5 Using a cutting station 12 .......................................................................................................................................

4. Using the Double Graphik tool head 14 .......................................................................................................................

4.1 Change the Graphik blades 14 ..................................................................................................................................

4.2 Adjust the blade depth and direction 16 ......................................................................................................................

4.3 Advanced cutting techniques 18 ...............................................................................................................................

5. Using the Fabric tool head 21 ....................................................................................................................................

5.1 Change the Fabric tool head blade 21 .........................................................................................................................

5.2 Use the Fabric tool head with a cutting mat 23 .............................................................................................................

5.3 Adjust the Fabric tool head blade pressure 24 ...............................................................................................................

5.4 Use the Fabric tool head blade guard 25 ......................................................................................................................

5.5 Fabric tool head cutting technique 26 .........................................................................................................................

6. Using the Creaser tool head 28 ..................................................................................................................................

6.1 Different creasing wheels 28 ...................................................................................................................................

6.2 Change the creasing wheels 29 ................................................................................................................................

6.3 Creasing technique 31 ............................................................................................................................................

7. Using the Rocker tool head 33 ...................................................................................................................................

7.1 The Rocker tool head 33 .........................................................................................................................................

7.2 Fit or change the Rocker tool head blade 34 .................................................................................................................

7.3 Rocker tool head cutting technique 35 ........................................................................................................................

8. Care and maintenance 38 .........................................................................................................................................

8.1 Clean your machine 38 ...........................................................................................................................................

8.2 Maintain the bearing track 39 ..................................................................................................................................

8.3 Change the sightline strip 40 ....................................................................................................................................