Page 5

DOC1049R (22 February 2024 12:07)

www.keit.co.uk Back to Table of Contents

8. Fit ports either side of the IRmadilloNA’s install point to allow clean-in-place or flushing

with a suitable cleaning fluid.

1.3. Checking for warnings and checking the probe is clean

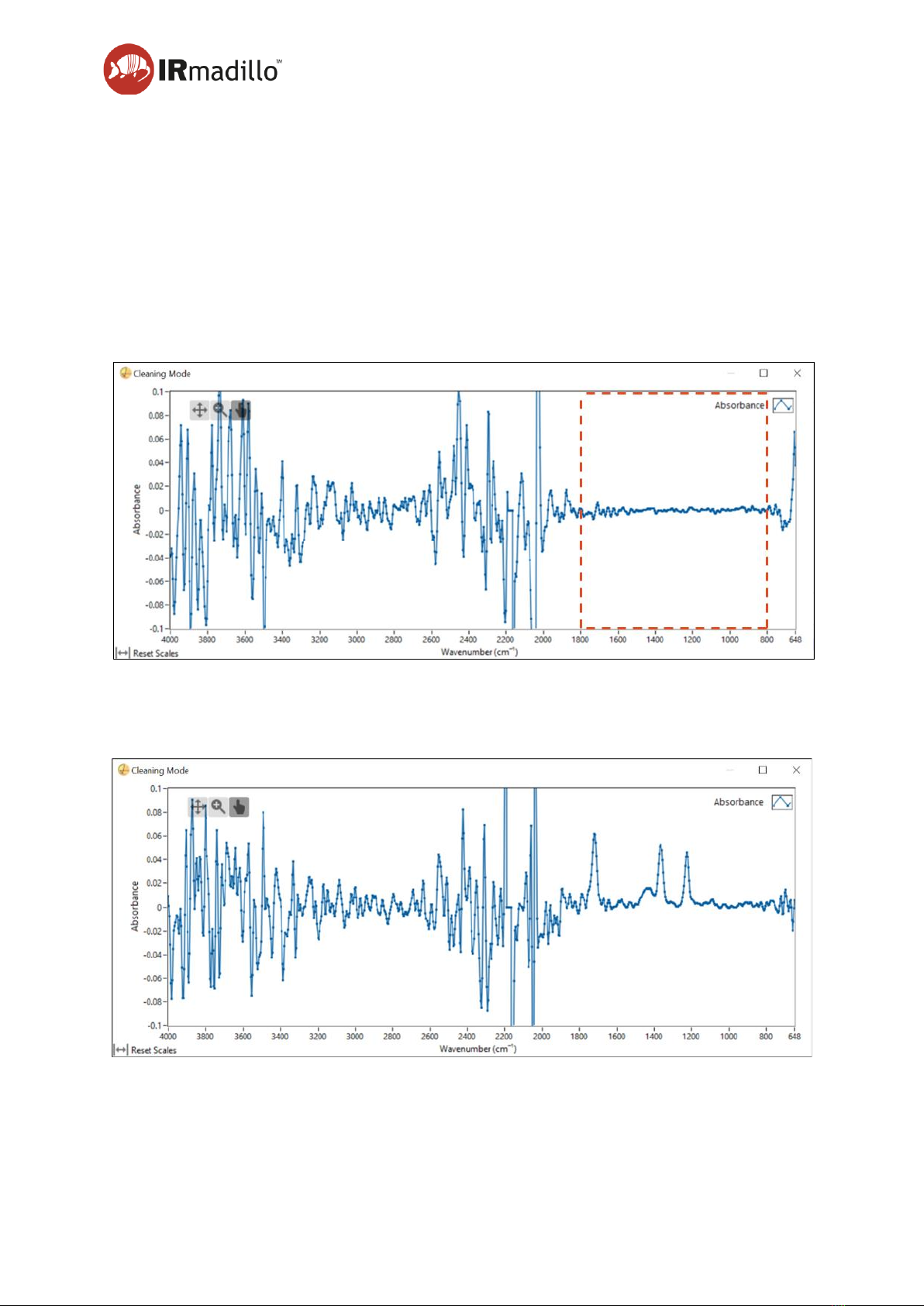

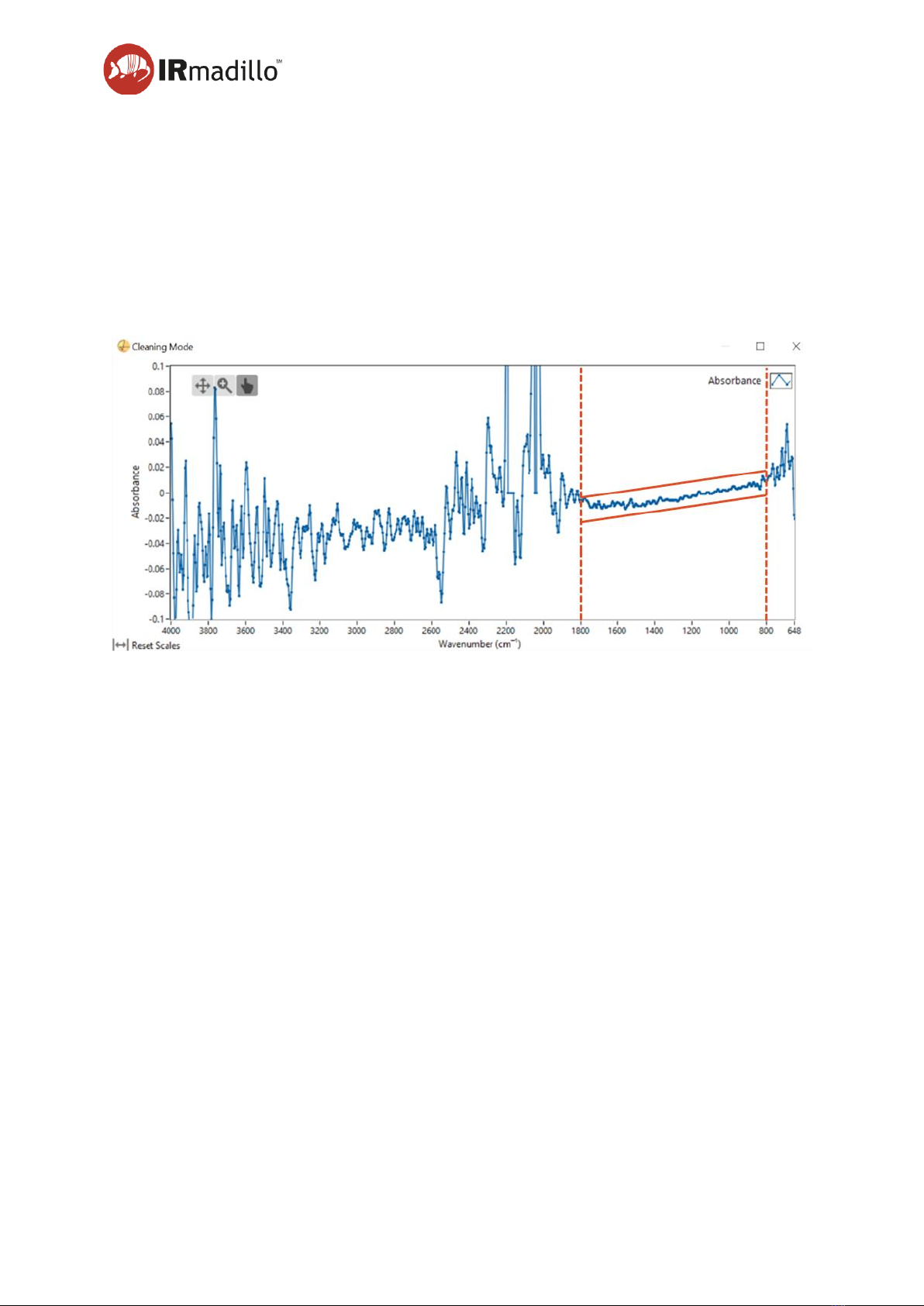

When you have connected to the powered-on IRmadilloNA the KeitSpec application should

load automatically (within 3 minutes). It is important to confirm that the system is working

without errors: information on IRmadilloNA warnings and errors can be found in DOC0893

KeitSpec Software User Manual, section 1, Getting Started.

Once the system is set up without errors, the probe tip must be cleaned, and a background

spectrum must be taken before insertion into the vessel or pipe. If the probe is guaranteed

clean, the factory background scan shipped with the instrument –and saved to the desktop of

the controller –can be used. Cleanliness of the probe tip is important to performance; if you

suspect fouling or scale build-up, perform a clean appropriate to your environment.

1.3.1. Cleaning instructions

Rinse the ATR element with a suitable solvent. The choice of solvent will depend on your

process. You may fully immerse the ATR in solvent if needed. The following are suitable:

•Water

•Acetone

•Alcohols

•Surfactant solutions

•Alkanes (hexane, cyclohexane etc…)

•Ethers

Once exposed to a suitable solvent, wipe the ATR with a clean cloth. The metal tube of the

probe can also be cleaned by wiping with a cloth.

For hard-to-remove fouling (such as biofilms or dried-on chemicals) Keit recommends an

oxidative acid clean. First, clean the ATR using the methods outlined above, then perform the

following: Souriau in-line plug

•If you have purchased one, place the PTFE sample cell on the end of the probe and

fill with ~4ml of 1 M nitric acid solution. If you have not purchased one then please

contact support@keit.co.uk for further information.

•Leave to soak for 1 hr

•Carefully remove the acid using a pipette and fill the sample cell with water

•Remove the water using a pipette

•Remove the sample cell and rinse the ATR again with water

•Carefully wipe the ATR with a cloth

It may be necessary to repeat the cleaning steps again if the contaminant has only been

partially removed.

In some cases, it may be necessary to perform an alkali clean on the probe. First clean the

ATR using the methods outline above, then perform the following:

•Place the PTFE sample cell on the end of the probe and fill with ~4ml of 1 M sodium

hydroxide solution

•Leave to soak for 1 hr

•Carefully remove the alkali using a pipette and fill the sample cell with water

•Remove the water using a pipette