Qonnex

Quick start 2-Wire v3.0

EMM.630(M)CT-MID (1A of 5A CT) and

EMM.630MCT-RC (Rogowski coils)

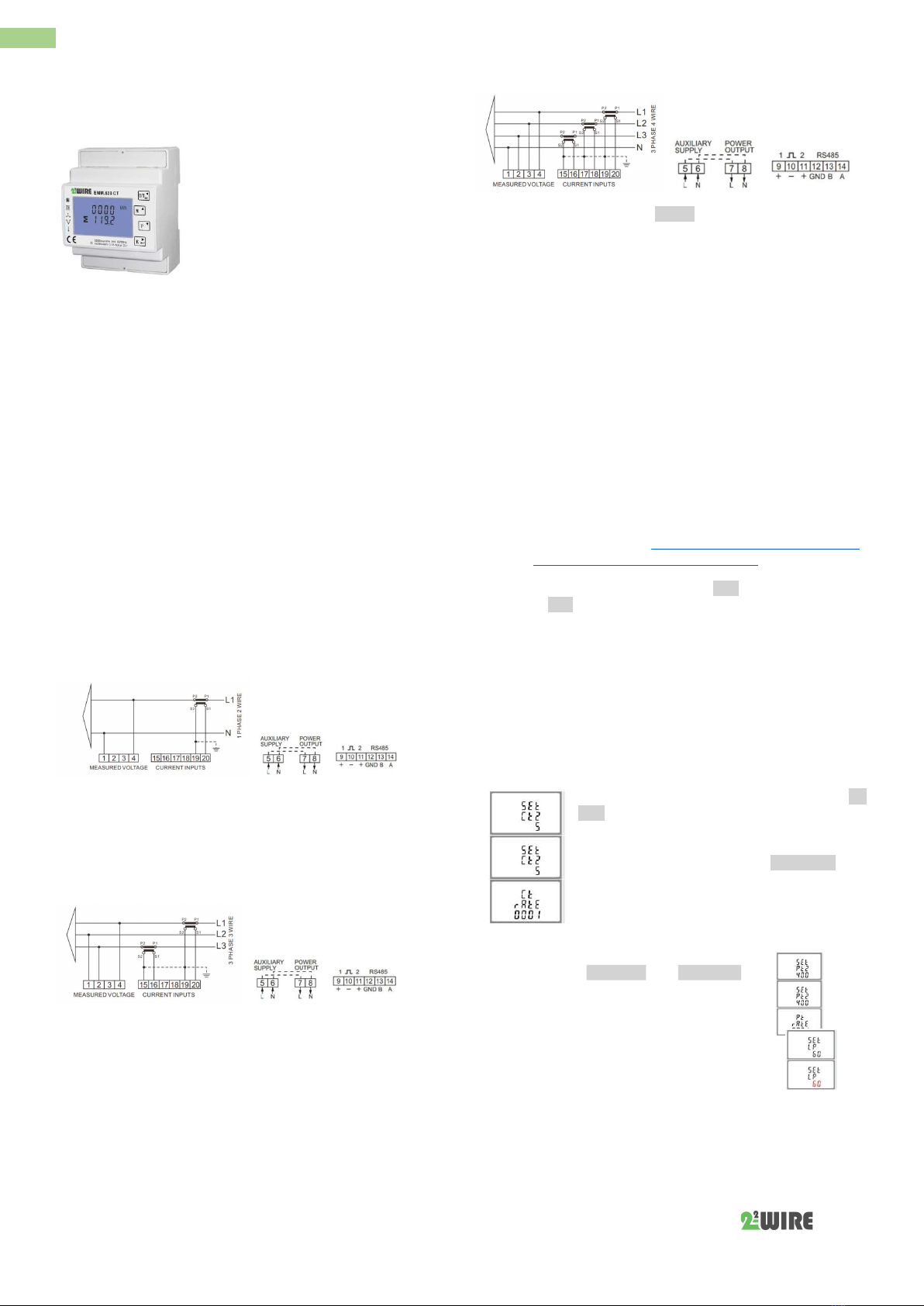

The EMM.630 (M)CT is an advanced 3 phase

energy monitor with direct connection to the

mains for measuring reference voltages and

3 connection for linking the current

transformers 1A or 5A CT or Rogowski coils

(EMM.630 MCT-RC) with which consumers

can be measured >100A. The configuration

of the meter is done via the touch keys on

the front panel and the LCD display. The bi-

directional measurement measures

consumption on mono, 3x230V or 3x380V+N

power supplies. Both active and reactive power are measured. The

readout of the consumption values can be done via the display or on the

linked web server. The module is packed in a 4 module wide DIN rail

housing. In addition to an RS485 connection, this energy meter also has 2

pulse outputs, of which 1 is configurable.

1. Connect:

Attention 1: To avoid voltage surge: first connect coil conductors to the

meter, only then clip coil around current conductors !! Install the power coil

only by a qualified electrician !!! Wear safety goggles during every operation

with the coils !!!

Attention 2: With the EMM.630 CT-MID, the type of coil can only be

entered once, see point 2. Configuration on display

Attention 3: After connecting the coils via display key "P" polarity check,

if negative power(Watt) or negative PF then open and turn coil, unless

there would be injection by solar panels!

Attention 4: The measured reference voltage and the measured current

must be at the same stage: ALWAYS test with voltmeter : Voltage

between conductor reference voltage and conductor flow pool must be

ZERO, otherwise you have a wrong measurement!! Here you can possibly

use the voltage drain terminals type UAD (see website)

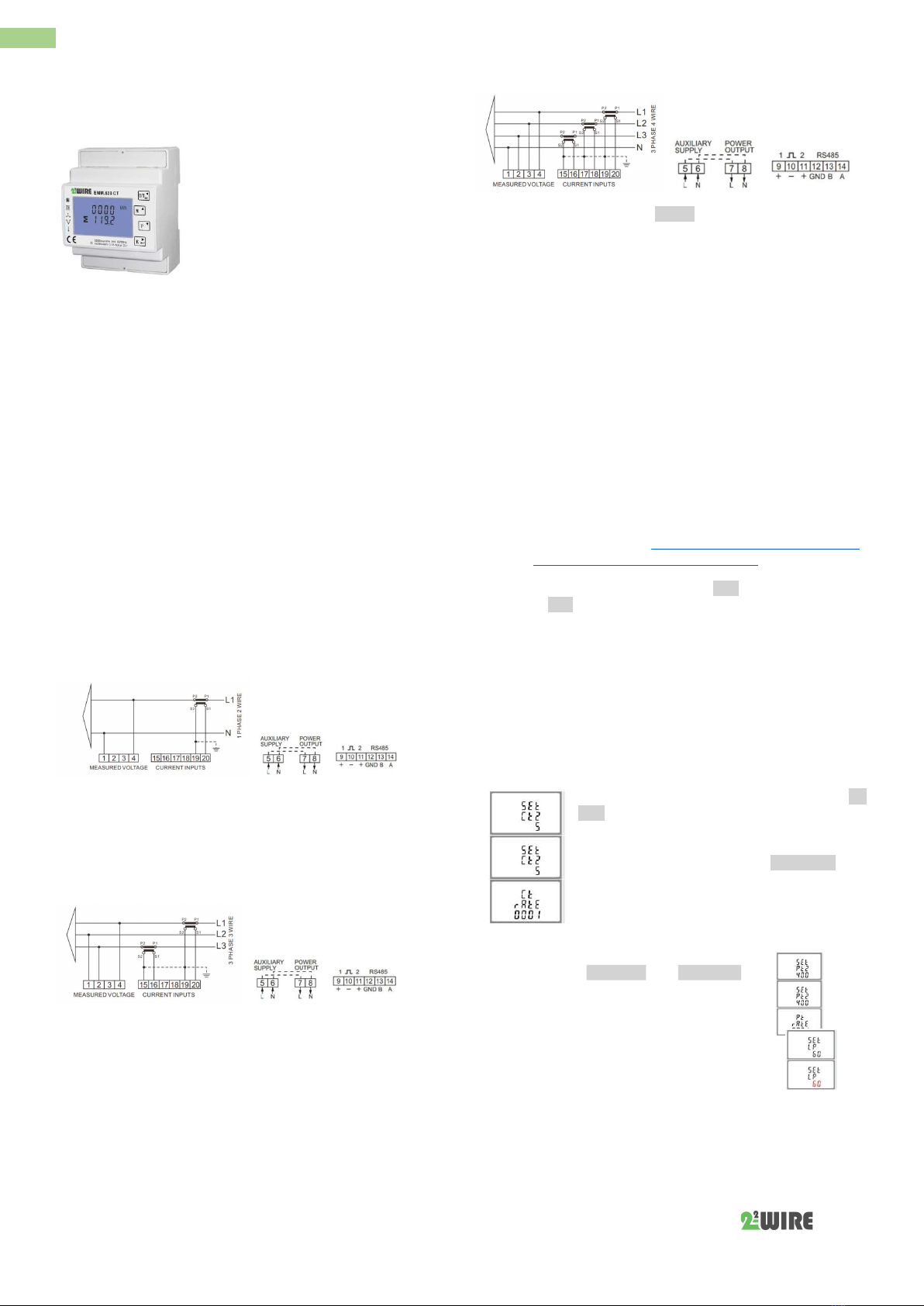

EMM.630 (M)CT: Mono-phase connection

On display: set as mono phase: SYS 1P2

Reference voltage: Neuter on Clamp 1; Phase on Clip 4

Flow coil: Keep flow arrow on coil, arrow points to Users! Black

conductor(=GND) on Clip 19; White conductor on Clip 20

Power voltage module: Neuter on Clamp 6,Phase on Clamp 5

Note: by-loop-Clamp to next meter Clamp 7= Clamp 5; Clip 8= Clamp6

Modbus connections: Clamp A (=13) and B (=14) and GROUND (=12 GND)

EMM.630 CT: 3x230V connection

On display: set as 3phase/3guider: SYS 3P3

Reference voltage: L1 on Clamp 4; L2 on Clamp 1; L3 on Clip 2

Flow coil: Keep current arrow on coil, arrow points to consumer!

Rinse L1: Black conductor (=GND) clamp 19; White conductor clamp 20

Rinse L2: Flow I2 (I1+I2+I3=0) is calculated, so does not need to be

measured and therefore no coil required! For this reason, no power is

logged in the Memo for this phase2.

Rinse L3:Black conductor (=GND) on clip 15; White conductor on clamp 16

Power supply voltage: Neuter on Clamp 6; Phase on Clip 5

Note : by-loop-Clamp to next meter:Clamp7= Clamp 5; Clip 8= Clamp6

Modbus connection: Clamp A (=14) and B (=13) and GROUND (=12 GND)

EMM.630 CT: 3x380V+N connection

On display: set as 3phase/3guider: SYS 3P4

Reference voltage: L1 on Clamp 4;; L2 on Clamp 3; L3 on Clamp 2;

N=Clamp 1

Flow coil: Keep current arrow on coil, arrow points to consumer!

Rinse L1: Black conductor (=GND) on Clip 19; White conductor on Clip 20

Rinse L2: Black conductor (=GND) on Clip 17; White conductor on Clip 18

Rinse L3: Black conductor (=GND) on Clip 15; White conductor on Clip 16

Power voltage module: Neuter on Clamp 6; Phase on Clip 5

Note: Loop-Clip to Next Meter Clip 7= Clip 5; Clip 8= Clamp6

Modbus connection: Clamp A (=14) and B (=13) and GROUND (=12 GND)

2: Configuration on the display:

This module is partly pre-configured and only needs to be entered:

a UNIQUE Modbus address, number between 1... 247

the type of power supply mono,3x230V,3x380V+N, standard at

3x380+N

the type of coil: be careful, this can only be done once and cannot

be adjusted afterwards!!!

How to get into SETUP:

(watch video tutorial) https://www.2-wire.net/en/product/3f-

energy-meter-ct-mid-modbus-emm-630-ct/)

Push the bottom button 4 (enter→)until PASS 0000 appears, fill in default

password PAS 1000 by pressing the button 2 (M↑) to 1, briefly press button

4 (enter) for next number or press enter for a long time to move to next

setting. Go through button 3 (P√) through the set values and adjust the

necessary Modbus values. Briefly press button 1 (U/I ←)) to leave menu.

Modbus parameters to be set: 9600 8N1

Modbus address : Id001... Id247

Baudrate: b 9600

Parity: Prty n (parity none)

Data: 8 bit

Stopbit: 1

Secondary current of the coil 1Ampere or 5Ampere: SET

Ct2 5 At the EMM.630CT-MID this can only be set

once!!

Multiplication factor = primary/ to secondary flow

strength of the coil, E.g. 100A/5A=20: Ct rATE 0020

With the EMM.630CT-MID this can only be set once!

In case Rogowski: CT1 should be set to 1kA, in the

EMM.630 MCT-RC meter you can still change settings

afterwards

ATTENTION:

1. The values SET Pt2 400 and Pt rAtE 0001 are

for high voltage and can only be adjusted once.

Leave it on DEFAULT! !

2. The backlight of the display can be set to

0/5/10/30/60/120.

0 stands for continuous, 5/10/30/60/120

means switch off after the set period . Here

better choose 5/10/30 to increase the service

life.

3: Configuration in the web server

In the web server, go to /configuration/modules: